Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the world of transportation, maintaining the integrity of temperature-sensitive goods is paramount. This is where truck refrigeration units come into play, ensuring that products such as food, pharmaceuticals, and flowers remain fresh during transit. What is a truck refrigeration unit? It’s a specialized system designed to provide consistent cooling in vehicles, often referred to as reefer trucks or simply refrigerated trucks.

The Importance of Truck Refrigeration

Truck refrigeration is crucial for businesses that rely on the timely delivery of perishable items. Without effective temperature control, products can spoil quickly, leading to significant financial losses and potential health hazards. Understanding what a truck reefer does not only helps businesses comply with safety regulations but also enhances customer satisfaction through reliable service.

Types of Refrigeration Units Available

When it comes to refrigeration units for trucks, there are several options available to suit various needs and budgets. From large-scale refrigerated trailers to compact van refrigeration units designed for urban deliveries, each type has its unique advantages. Small truck refrigeration units are particularly popular among local businesses due to their versatility and efficiency in navigating tight spaces while maintaining optimal cooling conditions.

Benefits of Investing in Quality Units

Investing in high-quality truck refrigeration units pays dividends in terms of performance and reliability. A well-built unit can drastically reduce energy consumption while ensuring that goods remain at the desired temperature throughout their journey—how does a truck fridge work? It circulates refrigerant through coils that absorb heat from inside the cargo area, effectively keeping everything chilled. Moreover, choosing reputable brands often results in better support and maintenance options down the line.

Understanding Truck Refrigeration Units

Key Features of Modern Units

Modern truck refrigeration units come equipped with a variety of advanced features that enhance their performance and efficiency. For instance, many units include digital thermostats for precise temperature control, allowing operators to monitor conditions in real-time. Additionally, insulation technology has improved significantly; high-quality materials help maintain consistent temperatures within the cargo area, whether you're using small truck refrigeration units or larger models.

Another standout feature is the integration of energy-efficient compressors that minimize fuel consumption while delivering powerful cooling capabilities. This is particularly important for businesses looking to reduce operational costs without sacrificing product quality. Furthermore, some models offer remote monitoring capabilities via smartphone apps, providing users with peace of mind and control over their refrigerated transport.

How Truck Refrigeration Works

So how does a truck fridge work? At its core, a truck refrigeration unit operates on the principles of thermodynamics and vapor compression cycles. The process begins with a refrigerant that absorbs heat from inside the cargo area and releases it outside through evaporators and condensers.

As the refrigerant circulates through the system, it changes states from liquid to gas and back again—essentially acting as a heat sponge that keeps your goods cool during transit. This continuous cycle ensures that perishable items remain at optimal temperatures throughout their journey while also maintaining humidity levels suitable for various types of cargo.

Truck Refrigeration Unit Efficiency

Efficiency in truck refrigeration units is not just about keeping things cold; it's also about doing so without wasting resources. Many modern refrigeration units for trucks are designed with energy conservation in mind—using advanced technologies to optimize performance while minimizing fuel usage. This efficiency becomes even more critical when considering long-haul deliveries where maintaining consistent temperatures over extended periods can be challenging.

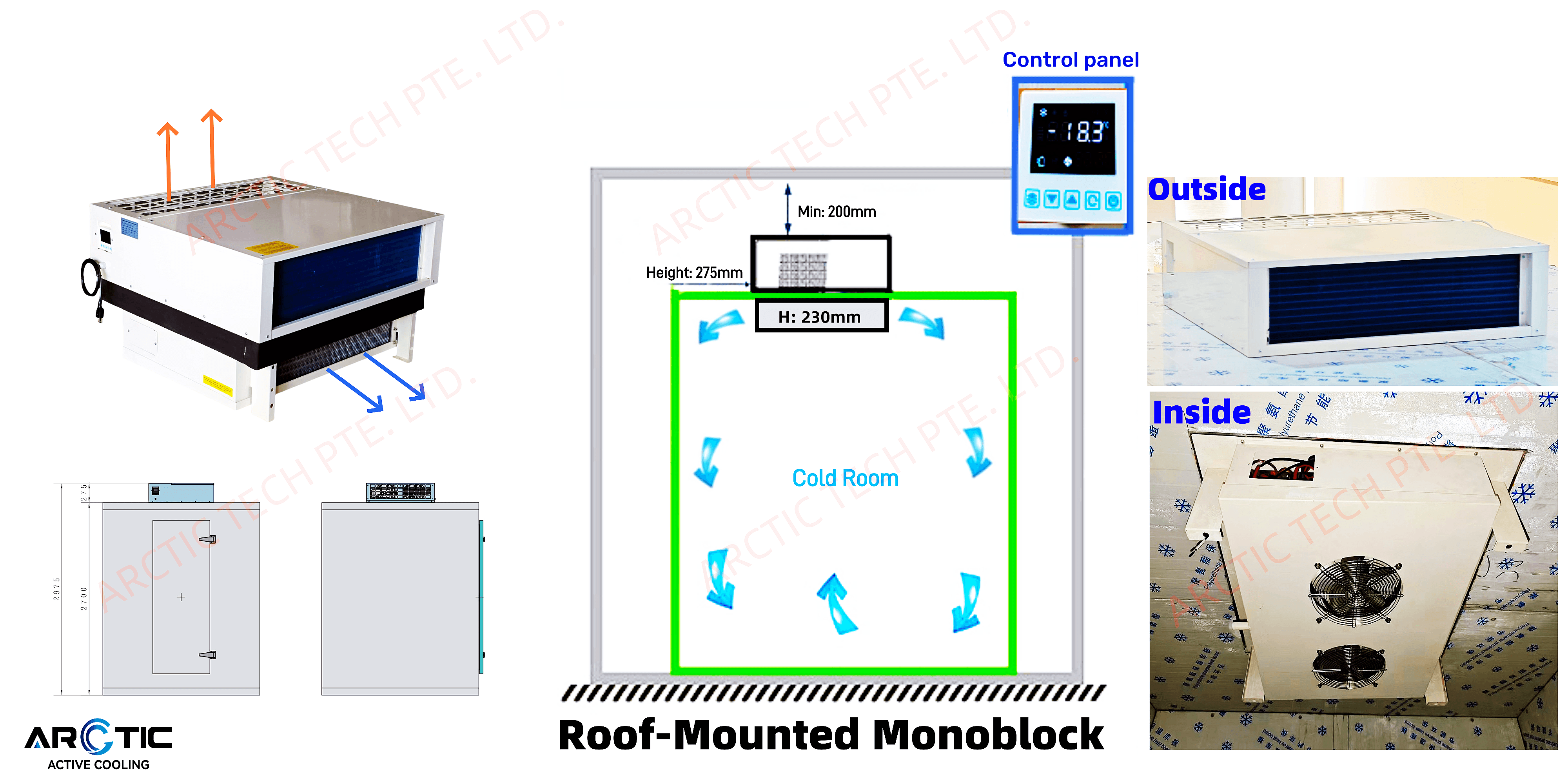

In addition to energy-efficient designs like those found in Arctic Active Cooling's Top-Mounted Monoblock Refrigeration Unit—which excels in commercial applications—regular maintenance plays a significant role in ensuring optimal efficiency as well. Keeping components clean and well-maintained helps prevent breakdowns and maximizes cooling performance across various applications like food delivery or floristry.

The Role of Trailers in Refrigeration

In the world of refrigerated transport, trailers play a crucial role in ensuring that temperature-sensitive goods arrive at their destinations safely and efficiently. When comparing refrigerated trailers to standard trailers, it's essential to understand the significant differences in design and functionality. A truck refrigeration unit is integrated into refrigerated trailers, allowing them to maintain optimal temperatures for perishable goods during transit.

Refrigerated Trailers vs. Standard Trailers

Refrigerated trailers, often referred to as reefer trailers, are specifically designed for transporting temperature-sensitive products like food and pharmaceuticals. Unlike standard trailers that lack insulation and cooling systems, refrigerated options utilize a truck refrigeration unit to maintain consistent temperatures regardless of external conditions. This makes them indispensable for businesses relying on cold chain logistics, where even minor temperature fluctuations can spoil valuable cargo.

When asking What is a truck refrigeration unit? it’s clear that these units come equipped with advanced technology tailored for efficient cooling and energy conservation. By investing in a refrigerated trailer over a standard one, companies can ensure compliance with health regulations while also enhancing product quality during transportation. Ultimately, the choice between these two types of trailers can significantly impact operational efficiency and customer satisfaction.

Popular Brands of Trailer Refrigeration Units

There are several reputable brands known for their reliable trailer refrigeration units that cater to various needs within the industry. Companies like Carrier Transicold and Thermo King lead the pack with innovative solutions that focus on energy efficiency and performance reliability. These brands offer an array of models suitable for different sizes of trucks—ranging from small truck refrigeration units ideal for local deliveries to larger systems designed for long-haul transport.

Another notable player is Arctic Active Cooling, recognized for its Top-Mounted Monoblock Refrigeration Unit which provides unparalleled efficiency tailored to commercial needs. This innovative system not only enhances cooling performance but also simplifies maintenance due to its all-in-one design—making it an attractive choice among fleet operators looking for reliability in their trailer refrigeration units. With so many options available, selecting the right brand often comes down to specific operational requirements and budget considerations.

Maintenance Tips for Trailers

Maintaining refrigerated trailers is critical not just for longevity but also for ensuring they perform at peak efficiency when transporting sensitive goods like fresh produce or pharmaceuticals. Regular checks on the truck refrigeration unit are essential; this includes monitoring coolant levels, inspecting seals and gaskets, and testing temperature controls frequently to avoid any unexpected breakdowns during transit.

Additionally, keeping the exterior clean helps prevent dirt buildup which can impede airflow around the condenser coils—this is especially important during warmer months when cooling demands increase significantly. Lastly, scheduling routine professional inspections can help catch potential issues before they become costly repairs or lead to product spoilage due to inadequate cooling performance.

Van Refrigeration Solutions

Benefits of Using Refrigerated Vans

Refrigerated vans provide numerous advantages over traditional delivery vehicles, primarily by maintaining consistent and controlled temperatures. This is essential for products like fresh produce, dairy, and meats that require specific conditions to prevent spoilage. Additionally, using a truck refrigeration unit can help businesses comply with health regulations while reducing waste due to spoilage—everyone wins!

Another key benefit is the versatility offered by van refrigeration units; they can be customized for various sizes and configurations to suit different business needs. Whether you’re looking at small truck refrigeration units or larger models, there’s an option available that fits your requirements perfectly. Plus, with advancements in technology, many modern refrigerated vans are equipped with energy-efficient systems that save on fuel costs while keeping your goods cool.

Best Refrigeration Units for Delivery Vans

Choosing the right refrigeration unit for your delivery van is crucial for ensuring optimal performance and reliability. Among the top contenders are the Arctic Active Cooling Monoblock Units which offer unparalleled efficiency tailored for commercial applications. With their innovative design and ability to maintain precise temperature control, these units stand out as some of the best options available.

For those seeking smaller alternatives, several manufacturers offer compact truck refrigeration units ideal for urban delivery routes where space may be limited. These small truck refrigeration units are designed without compromising on cooling performance while maximizing cargo space—perfect for city dwellers! It's important to assess your specific needs before making a decision; whether you require a robust system or something more streamlined will depend on what you're transporting.

Case Studies of Successful Refrigerated Vans

Many businesses have thrived by incorporating refrigerated vans into their logistics operations; one notable example is a local bakery that transitioned from standard delivery vehicles to refrigerated ones. By utilizing efficient van refrigeration units, they were able to expand their product range significantly without worrying about spoilage during transit—a sweet success story indeed! Customers began noticing fresher products upon arrival which directly led to increased sales and loyalty.

Another case study involves a floral shop that adopted Arctic Active Cooling's Monoblock Units in their fleet of refrigerated vans. This allowed them not only to transport flowers at optimal humidity but also enhanced their reputation within the industry as providers of high-quality blooms—talk about blooming success! The ability to deliver fresh flowers consistently has transformed how they approach logistics and inventory management.

Advanced Technology in Refrigeration

In the world of truck refrigeration, advancements in technology have revolutionized how we keep perishable goods fresh during transport. From sophisticated cooling systems to energy-efficient designs, modern refrigeration units for trucks are not only enhancing performance but also addressing sustainability concerns. Understanding these innovations is crucial for anyone involved in cold chain logistics or seeking to invest in a reliable truck refrigeration unit.

The Arctic Active Cooling Monoblock Unit

One standout innovation is the Arctic Active Cooling Monoblock Unit, which offers unparalleled efficiency and reliability for various cooling applications. This advanced unit is specifically engineered for commercial refrigerators and freezers, making it an excellent choice for businesses that require optimal temperature control. Whether you’re transporting delicate flowers or perishable food items, this all-in-one solution ensures that your cargo remains at the right temperature and humidity levels throughout its journey.

The Arctic Monoblock unit is particularly effective in maintaining optimal conditions for storing fresh flowers, making it a favorite among florists and wholesale flower markets. Its design allows seamless integration into refrigerated trailers or vans, showcasing its versatility across different vehicle types. When considering what is a truck refrigeration unit that meets high standards of performance and convenience, the Arctic Active Cooling Monoblock stands out as an exceptional option.

How Technology Enhances Efficiency

Modern truck refrigeration units are equipped with cutting-edge technology that significantly enhances their efficiency compared to older models. Features such as digital temperature controls allow drivers to monitor conditions in real-time, ensuring that goods remain within specified temperature ranges during transit. Additionally, many units now come with automated defrost cycles and improved insulation materials that reduce energy consumption while maintaining optimal cooling performance.

Understanding how does a truck fridge work can help operators maximize their investment; efficient units lead to lower operating costs over time due to reduced fuel consumption and maintenance needs. Moreover, advancements like variable speed compressors adjust cooling output based on load requirements, further improving energy efficiency without compromising on performance. In essence, investing in modern refrigeration units for trucks means you're not just buying equipment; you're enhancing your operational capabilities.

Innovations in Energy Conservation

As environmental concerns continue to rise globally, innovations aimed at energy conservation are becoming increasingly important within the trucking industry. Many manufacturers are now focusing on creating small truck refrigeration units that consume less power while still providing robust cooling capabilities necessary for transporting sensitive goods like pharmaceuticals or perishables. These innovations not only help businesses save money but also contribute positively to reducing their carbon footprint.

For instance, some newer models incorporate solar panels or hybrid systems designed to use renewable energy sources when available—an excellent way of answering the question: what is truck reefer technology doing for sustainability? Furthermore, improved insulation techniques minimize thermal loss during transport so less energy is required overall. By embracing these advancements in energy conservation technologies within their fleets, companies can enjoy both economic benefits and enhanced reputations as environmentally responsible operators.

Industry Applications for Refrigerated Vehicles

Refrigerated vehicles are essential in various industries, ensuring that temperature-sensitive goods reach their destinations safely and efficiently. The versatility of truck refrigeration units makes them indispensable in food delivery, logistics, and even niche markets like floristry. Understanding how these vehicles operate can help businesses maximize their investment in refrigerated transport.

Food and Beverage Delivery Needs

When it comes to food and beverage delivery, the reliability of a truck refrigeration unit is paramount. These units maintain the necessary temperatures to preserve freshness, preventing spoilage during transit. Whether it's a small truck refrigeration unit for local deliveries or larger reefer trucks for long hauls, having the right equipment ensures that products arrive in prime condition.

The demand for quality refrigerated transport has never been higher, especially with consumers increasingly favoring fresh produce and gourmet items. A well-functioning truck fridge not only keeps food safe but also enhances customer satisfaction by delivering top-notch products. In this competitive market, investing in quality refrigeration units for trucks can set businesses apart from the rest.

Cold Chain Logistics Essentials

Cold chain logistics play a crucial role in maintaining product integrity from point A to point B. What is a truck refrigeration unit? Simply put, it's an integral part of cold chain logistics that ensures temperature-sensitive goods remain within required temperature ranges throughout transportation. For companies relying on these systems, understanding how does a truck fridge work is essential for optimizing routes and minimizing losses due to spoilage.

Advanced technology has made it possible to monitor temperatures in real-time using van refrigeration units equipped with smart sensors. This feature allows businesses to respond quickly if any deviations occur during transit—effectively safeguarding their investments. With the rise of e-commerce and online grocery shopping, efficient cold chain logistics have become more vital than ever before.

Unique Uses in Floristry and Beyond

Refrigerated vehicles aren't just about transporting food; they also serve unique applications like floristry! The delicate nature of flowers requires specific climate conditions that only specialized truck reefer units can provide. Maintaining optimal humidity and temperature is crucial for keeping blooms fresh during transit—something that Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit excels at.

These innovative units are designed not just for standard cooling but also cater specifically to the needs of flower markets by preserving freshness through controlled environments. With features tailored to small business needs or larger operations alike, they represent a smart investment for florists looking to enhance their service offerings. From wedding bouquets to wholesale flower deliveries, understanding what is a refrigerator truck called helps clarify its importance in this niche market.

Conclusion

In the world of logistics and transportation, selecting the right truck refrigeration unit is crucial for maintaining product integrity. With various options available, including small truck refrigeration units and advanced van refrigeration units, businesses must carefully evaluate their needs. A well-chosen refrigeration unit can enhance efficiency, reduce spoilage, and ultimately contribute to a company's bottom line.

Choosing the Right Refrigeration Unit

When pondering What is a truck refrigeration unit? it's essential to consider factors such as size, capacity, and the specific goods being transported. Whether you need a robust truck reefer for large shipments or smaller units for niche markets, understanding your requirements will guide your decision-making process. Remember that investing in quality refrigeration units for trucks not only ensures freshness but can also lead to long-term savings.

For those wondering What is a refrigerator truck called?, it’s often referred to as a reefer truck or refrigerated van. These vehicles are designed with specialized insulation and cooling systems that keep products at optimal temperatures during transit. By analyzing features like temperature control capabilities and energy efficiency ratings, you can make an informed choice tailored to your business's unique demands.

Future Trends in Truck Refrigeration

The future of truck refrigeration looks promising with trends leaning towards sustainability and technological advancements. Innovations such as Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit are setting new standards in performance while maintaining environmental responsibility. As businesses increasingly prioritize energy conservation, these modern solutions will play a pivotal role in shaping efficient cold chain logistics.

Additionally, advancements in smart technology are enhancing how we monitor and manage temperature controls within refrigerated vehicles. With real-time tracking capabilities becoming more prevalent, companies can ensure compliance with cold chain requirements effortlessly. This shift towards automation not only simplifies operations but also opens doors to new possibilities in refrigerated transport.

Maximizing Investment in Refrigerated Transport

To maximize your investment in refrigerated transport, regular maintenance of your chosen truck refrigeration unit is key. Routine checks on components like compressors and evaporators ensure optimal performance over time while preventing costly breakdowns during critical deliveries. Moreover, training staff on best practices for operating these units reinforces their longevity and reliability.

It's also wise to stay updated on emerging technologies that could enhance your existing systems—like integrating energy-efficient van refrigeration units or exploring options for small truck refrigeration units designed specifically for urban deliveries. By being proactive about improvements and maintenance strategies, you can maintain high service levels while minimizing operational costs effectively.