Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

Walk-in coolers are essential components in the world of cold storage and cold chain logistics. These large refrigerated spaces are designed to maintain specific temperatures for various products, from perishable foods to pharmaceuticals. Understanding the main components of walk-in coolers, including their refrigeration systems and cooling fans, is crucial for ensuring optimal performance and efficiency.

Overview of Walk-in Coolers

Walk-in coolers serve as a cornerstone in many industries that require precise temperature control for their products. These cold storage rooms not only provide ample space for storing goods but also ensure that items remain fresh and safe from spoilage. With advancements in refrigeration technology, modern walk-in coolers are equipped with sophisticated features that enhance their functionality.

Importance of Components

The effectiveness of walk-in coolers heavily relies on their individual components working harmoniously together. Key elements such as condensing units, refrigeration compressors, and cold storage fans play significant roles in maintaining the desired climate within these spaces. Each component contributes to the overall efficiency and reliability of the cooling system, making it vital to understand their functions.

How They Work Together

In a well-designed walk-in cooler, every component has a specific role that contributes to its overall operation. For instance, the refrigeration compressor pumps refrigerant through the system while the condensing unit dissipates heat outside the cooler environment. Meanwhile, fans for cooling circulate air throughout the space, ensuring even temperature distribution—highlighting how these elements collaborate seamlessly to uphold optimal conditions within cold storage rooms.

Basic Structure of Walk-in Coolers

Walk-in coolers are designed with a robust structure that plays a crucial role in maintaining the desired temperature for perishable goods. The main components of walk-in coolers include insulation panels, wall and ceiling designs, and various floor types, all working together to create an efficient cold storage environment. Understanding these elements not only helps ensure proper functionality but also highlights the importance of choosing high-quality materials from reputable suppliers.

Insulation Panels

Insulation panels are the backbone of any effective walk-in cooler, providing thermal resistance that keeps cold air inside while blocking heat from the outside. Made from materials like polyurethane or polystyrene, these panels minimize energy loss and enhance overall efficiency—key factors for any cold storage room. When selecting insulation panels, consider options from leading cold storage fans manufacturers who also offer integrated solutions for refrigeration technology.

Wall and Ceiling Designs

The design of walls and ceilings in walk-in coolers is essential for maximizing space and ensuring optimal airflow throughout the structure. Smooth surfaces are preferred as they facilitate easy cleaning and maintenance while preventing bacteria buildup—a critical factor in food safety compliance. Additionally, incorporating features such as reinforced corners can help support heavy condensing units that house refrigeration compressors necessary for maintaining consistent temperatures.

Floor Types

Choosing the right floor type is vital for both functionality and durability in a walk-in cooler setting. Floors must be designed to withstand heavy loads while being resistant to moisture accumulation; common materials include concrete or epoxy coatings that provide excellent durability and ease of cleaning. Proper flooring not only supports equipment like cold storage fans but also ensures a safe environment by preventing slips or accidents within the cold chain logistics.

Refrigeration Systems

Refrigeration systems are the heart of walk-in coolers, ensuring that temperatures remain consistently low for optimal storage conditions. A well-designed refrigeration unit not only maintains the required temperature but also enhances energy efficiency, ultimately contributing to lower operational costs. Understanding the components of these systems is crucial for anyone involved in cold storage and cold chain logistics.

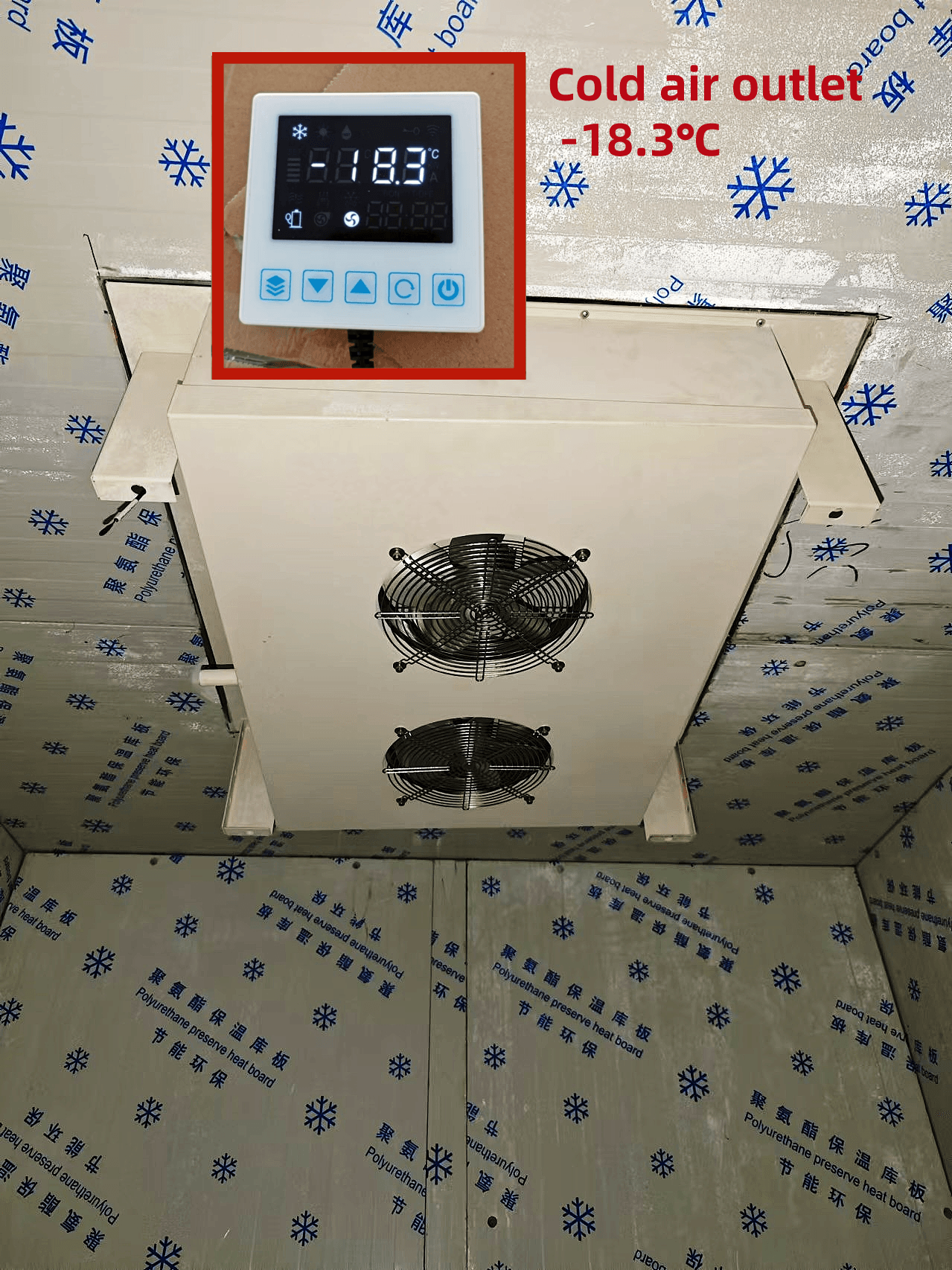

Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit

The Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit stands out as a premier choice for businesses looking to optimize their cold storage room operations. This innovative unit is engineered to deliver exceptional performance while maintaining optimal humidity and temperature levels, making it ideal for diverse applications—from keeping fresh flowers vibrant at florists to ensuring food products stay safe and fresh. Its all-in-one design combines a condensing unit and refrigeration compressor, simplifying installation and maintenance processes while maximizing efficiency.

Key Features of Refrigeration Units

When evaluating refrigeration units, several key features should be considered to ensure they meet specific needs in cooling and refrigeration technology. High-quality refrigeration compressors play a vital role in maintaining consistent temperatures by effectively managing refrigerant flow within the system. Additionally, advanced controls enable precise monitoring of temperature settings, while robust insulation panels enhance overall energy efficiency—making these units indispensable main components of walk-in coolers.

Importance of Energy Efficiency

Energy efficiency is not just a buzzword; it’s a critical factor in the sustainability of any cold storage operation. By investing in high-efficiency refrigeration systems like those from leading cold storage fans manufacturers, businesses can significantly reduce their energy consumption without sacrificing performance or reliability. This commitment to energy-efficient solutions not only lowers operating costs but also contributes positively to environmental conservation efforts within the cold chain industry.

Cold Storage Fans

Cold storage fans play a critical role in maintaining the efficiency and effectiveness of walk-in coolers. These fans are essential for ensuring that cold air is evenly distributed throughout the cold storage room, preventing hot spots and maintaining consistent temperatures. By facilitating proper airflow, they help optimize refrigeration technology, which is vital for preserving perishable goods.

Role of Cold Storage Fans

The primary function of cold storage fans is to circulate air within the cold storage room, ensuring that all items receive uniform cooling. This circulation prevents condensation build-up and minimizes the risk of spoilage, making them one of the main components in walk-in coolers. Additionally, well-placed fans can enhance the performance of condensing units and refrigeration compressors by allowing them to operate more efficiently.

Cold storage fans also contribute to energy savings by reducing the workload on refrigeration systems. When air circulates effectively, it helps maintain desired temperatures without overburdening cooling equipment. This balance not only prolongs the life of refrigeration units but also aligns with modern sustainability goals in cold chain management.

Leading Cold Storage Fans Manufacturer

As a leader in refrigeration technology, Arctic Active Cooling offers a variety of fan solutions that cater to different sizes and types of cold storage rooms. Their commitment to energy efficiency ensures that businesses can maintain temperature control without incurring excessive operational costs. Furthermore, their expertise extends beyond just manufacturing; they provide comprehensive support for installation and maintenance.

Choosing a reputable manufacturer like Arctic Active Cooling guarantees that your cooling systems will be equipped with high-performance fans designed for longevity and reliability. With an emphasis on innovation and customer satisfaction, they stand out as a trusted partner in the world of cold chain logistics.

Proper Fan Placement for Optimal Circulation

Proper placement of cold storage fans is crucial for achieving optimal circulation within any walk-in cooler or refrigerator system. Strategically positioning these fans allows them to distribute cool air effectively across all areas of the space while avoiding dead zones where warm air might linger unchallenged. Typically located near ceilings or high-traffic areas ensures maximum airflow throughout the entire room.

In addition to placement height considerations, it's essential to evaluate how many fans are necessary based on room size and configuration—more extensive spaces may require multiple units working together harmoniously for effective temperature regulation. Collaborating with professionals during installation can help determine ideal fan layouts tailored specifically for each unique environment.

Finally, regular maintenance checks should include fan functionality assessments—ensuring blades are clean and unobstructed contributes significantly toward efficient operation over time. By prioritizing proper fan placement alongside routine upkeep practices, businesses can achieve long-lasting benefits from their investment in cooling technology while preserving product integrity within their cold storage environments.

Temperature Control Mechanisms

Temperature control is a critical aspect of maintaining the integrity of products stored in walk-in coolers. Proper temperature regulation ensures that perishable goods remain fresh and safe for consumption, making it essential for businesses operating within the Cold Chain. The main components of walk-in coolers work in harmony to achieve optimal conditions, with thermostats, digital monitoring solutions, and consistent temperature maintenance playing pivotal roles.

Thermostats and Controls

Thermostats are the brain behind any effective refrigeration system, including walk-in coolers. They regulate the operation of the Condensing Unit and Refrigeration Compressor by maintaining set temperature levels within the cold storage room. These controls not only allow for manual adjustments but also enable automatic responses to fluctuations in temperature, ensuring that products remain at their ideal storage conditions.

The integration of advanced controls allows operators to monitor and adjust temperatures easily, providing peace of mind that their goods are protected. When it comes to efficiency, modern thermostats can optimize energy consumption by adjusting cooling cycles based on current needs—an essential feature given today's focus on sustainability in refrigeration technology. By choosing reliable cold storage fans manufacturer products alongside these systems, businesses can further enhance their cooling capabilities.

Digital Monitoring Solutions

In today’s tech-savvy world, digital monitoring solutions have revolutionized how we manage temperature control in cold storage environments. These systems provide real-time data about temperature fluctuations and humidity levels within walk-in coolers, allowing for immediate corrective actions if necessary. Many solutions include alerts or notifications sent directly to mobile devices or computers when temperatures deviate from set parameters.

Digital monitoring not only enhances operational efficiency but also supports compliance with health regulations that require strict adherence to specific temperature ranges for food safety or pharmaceutical storage. By integrating these technologies with high-quality fans for cooling, businesses can create an environment where temperature stability is prioritized without sacrificing energy efficiency or performance. The synergy between advanced monitoring systems and reliable refrigeration units helps maintain a seamless Cold Storage experience.

Importance of Consistent Temperatures

Maintaining consistent temperatures is crucial for preserving product quality in any cold storage room setting. Fluctuations can lead to spoilage or degradation of sensitive items such as perishables or pharmaceuticals—consequences that no business wants to face! Regularly monitored temperatures ensure that items are kept within safe parameters while maximizing shelf life.

Moreover, consistent temperatures contribute significantly to operational efficiency by reducing wear and tear on refrigeration components like the Condensing Unit and Refrigeration Compressor; this ultimately leads to lower maintenance costs over time. Businesses investing in high-quality cold storage fans manufacturer equipment will find that proper airflow complements their cooling efforts by preventing hot spots and ensuring uniformity throughout the space—key factors in achieving optimal performance across all aspects of Cold Chain management.

Access and Security Features

Access and security features are critical components in the design of walk-in coolers, ensuring that both the stored items and the facility remain protected. From entry systems to surveillance measures, these elements work together to create a secure environment for cold storage. In addition, compliance with health regulations is paramount for businesses dealing with perishable goods.

Doors and Entry Systems

The doors of walk-in coolers are often designed with insulation in mind to maintain optimal temperatures within cold storage rooms. These entry systems can vary from standard hinged doors to more advanced options like sliding or roll-up doors, which provide ease of access while minimizing temperature fluctuations. High-quality seals around these doors enhance energy efficiency by preventing cold air from escaping, which is essential when using refrigeration compressors and condensing units.

Security Locks and Surveillance

Security locks are an indispensable feature for walk-in coolers, ensuring that only authorized personnel have access to valuable inventory. Many modern systems incorporate advanced locking mechanisms along with surveillance cameras to monitor entries and exits continuously. For businesses relying on cold chain logistics, such security measures not only protect assets but also help maintain compliance with industry regulations regarding food safety.

Compliance with Health Regulations

Compliance with health regulations is crucial for any business operating a cold storage room, especially those in the food service or pharmaceutical sectors. Walk-in coolers must adhere to strict guidelines regarding temperature control, sanitation, and security protocols; failure to comply can lead to significant penalties or loss of licenses. By investing in high-quality equipment—such as reliable refrigeration technology from reputable cold storage fans manufacturers—businesses can ensure they meet these essential requirements while maintaining product integrity.

Conclusion

In summary, walk-in coolers are essential for various industries, providing efficient cold storage solutions that maintain the integrity of perishable goods. Understanding the main components of these systems, including refrigeration compressors and condensing units, is crucial for optimizing performance and longevity. The interplay of advanced technology and quality materials ensures that businesses can rely on their cold storage rooms to meet stringent temperature requirements.

Key Components of Walk-in Coolers

The main components of walk-in coolers include insulation panels, refrigeration systems, and cold storage fans. Each element plays a vital role in maintaining a stable environment for stored items while minimizing energy consumption. For instance, high-quality cold storage fans from reputable manufacturers help circulate air evenly, preventing hot spots that could compromise the quality of goods.

Benefits of Modern Refrigeration Systems

Modern refrigeration systems, such as the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit, offer numerous advantages for businesses reliant on Cold Chain logistics. These units provide unparalleled efficiency and reliability while ensuring optimal humidity levels for sensitive products like fresh flowers in florists or wholesale markets. With energy-efficient designs and advanced control mechanisms, businesses can significantly reduce operational costs while enhancing product preservation.

Importance of Regular Maintenance

Regular maintenance is essential to ensure that all components—such as the refrigeration compressor and condensing unit—function effectively over time. Neglecting routine checks can lead to decreased efficiency and unexpected breakdowns in your cold storage room, which could jeopardize your inventory's safety. By partnering with a trusted cold storage fans manufacturer and adhering to maintenance schedules, businesses can extend the lifespan of their cooling systems while ensuring compliance with health regulations.