Introduction

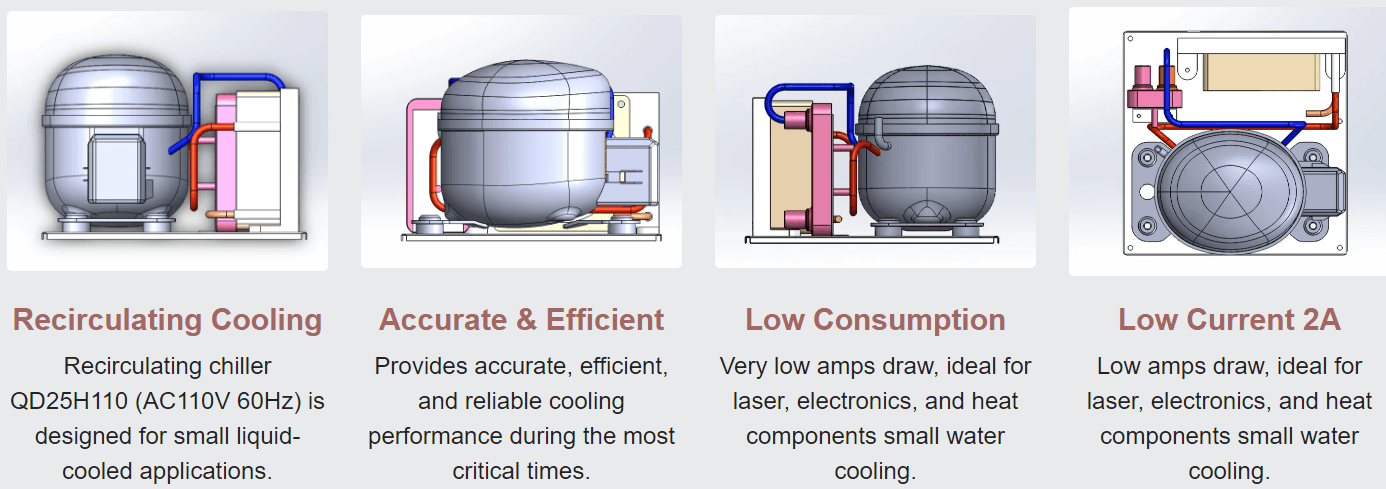

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

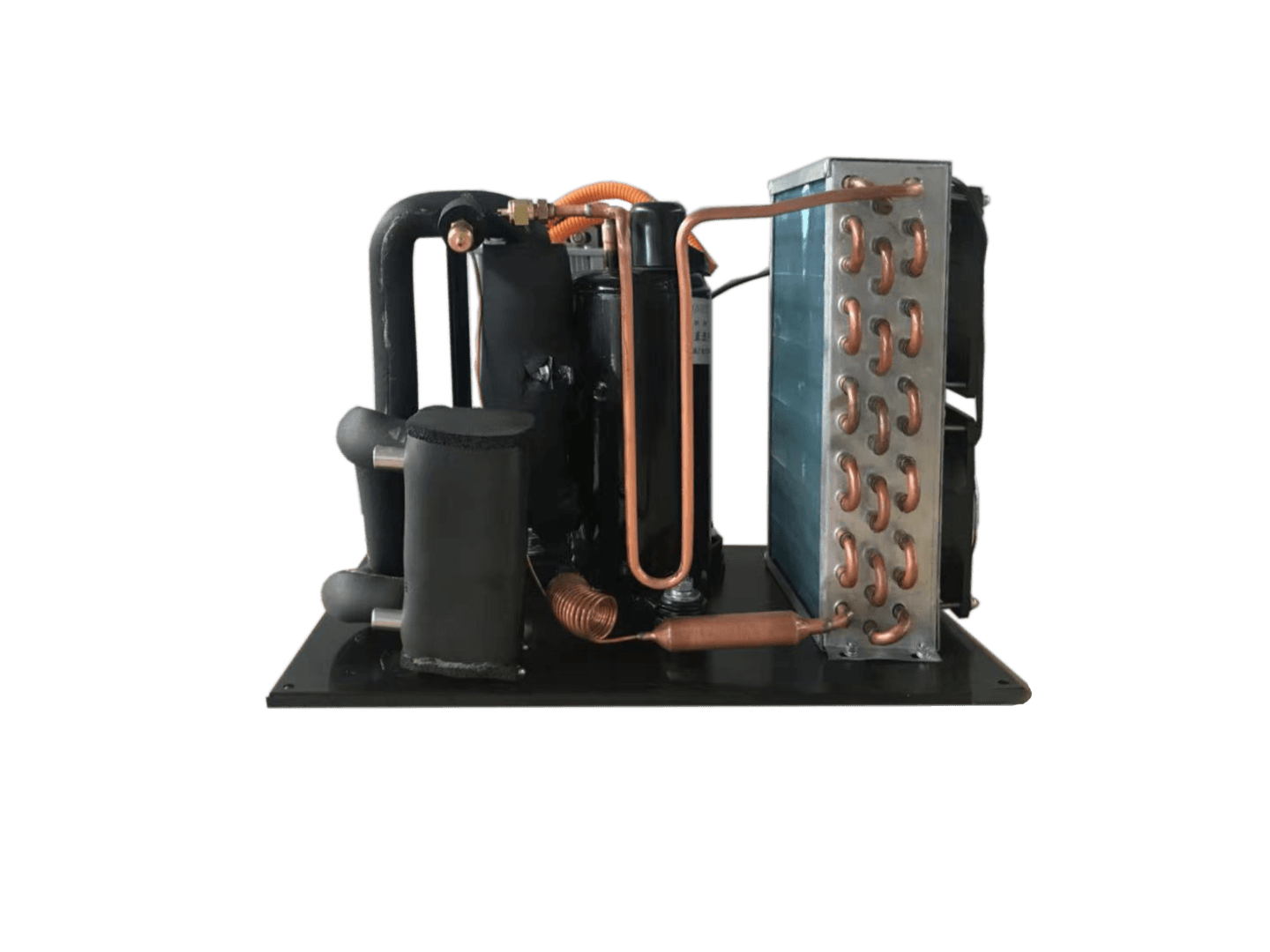

Understanding Water Cooled Condensing Units

A water cooled condensing unit operates by using water as a medium for heat exchange, providing effective cooling in various commercial applications. Unlike air cooled units that rely on ambient air to dissipate heat, these systems utilize circulating water to maintain optimal temperatures. This fundamental difference not only improves performance but also allows for more compact installations in environments where space is at a premium.

Benefits of Water Cooled Systems

The adoption of water cooled systems brings forth numerous advantages, particularly in energy efficiency and cost savings. With their ability to operate effectively even in high ambient temperatures, these units reduce the load on compressors and lead to lower energy bills over time. Additionally, the reduced footprint for installation makes them an ideal choice for businesses looking to maximize space while maintaining powerful refrigeration capabilities.

Key Components of Refrigeration Systems

At the heart of any effective refrigeration system lies its key components: the compressor, condenser unit compressor, evaporator coil, and expansion valve. In a water cooled condensing unit setup, the condenser plays a pivotal role in expelling heat absorbed from the refrigerant during its cycle. Understanding how each component interacts within the system helps ensure optimal performance and longevity of your refrigeration solutions.

Water Cooled Condensing Unit Explained

Water cooled condensing units are essential components in commercial refrigeration systems, providing efficient cooling through a unique method of heat exchange. Unlike air cooled systems that rely on ambient air, these units utilize water to absorb and dissipate heat, making them particularly effective in environments where space is at a premium or cooling demands are high. By harnessing the power of water, these condensing units can operate more efficiently and effectively under various conditions.

What is a Water Cooled Condensing Unit

A water cooled condensing unit is a type of refrigeration system that uses water as the medium for heat transfer instead of air. This unit consists of several key components including a condenser coil, compressor, and evaporator, all working together to remove heat from the refrigerant circulating through the system. The design allows for more compact installations and improved efficiency compared to traditional air cooled units.

How it Works in Commercial Refrigeration

In commercial refrigeration applications, the water cooled condensing unit operates by circulating refrigerant through its system while simultaneously using water to cool the condenser coils. As the refrigerant absorbs heat from inside the refrigerated space, it changes from a liquid to a gas before entering the condenser unit compressor. The compressor then pressurizes this gas and sends it to the condenser where it releases heat into the flowing water before returning to its liquid state—ready to continue cooling.

Common Applications in Various Industries

Water cooled condensing units find their place in numerous industries due to their efficiency and reliability. Common applications include supermarkets where large volumes of refrigerated goods require constant temperature control; industrial settings that need robust cooling solutions for machinery; and food processing facilities that prioritize hygiene alongside effective temperature management. These versatile systems prove indispensable across sectors such as hospitality, pharmaceuticals, and manufacturing.

Advantages of Using Water Cooled Units

Water cooled units are gaining traction in the commercial refrigeration sector for a multitude of reasons. These systems are not only efficient but also offer significant savings and a smaller physical footprint, making them ideal for various applications. Let's delve into the specific advantages that make water cooled condensing units a top choice for businesses.

Energy Efficiency and Cost Savings

One of the standout features of water cooled condensing units is their impressive energy efficiency, which directly translates to cost savings for businesses. By utilizing water as a cooling medium, these systems can operate at lower temperatures compared to air cooled counterparts, resulting in reduced energy consumption. Over time, this efficiency can lead to substantial reductions in operational costs, making water cooled systems an economically sound investment.

Additionally, many commercial refrigeration setups face high cooling demands during peak hours; water cooled units excel in these scenarios by maintaining performance without excessive energy use. This ability to deliver consistent cooling not only helps preserve product quality but also minimizes electricity bills month after month. In essence, choosing a water condensing unit is a strategic move that pays off in both immediate and long-term financial benefits.

Reduced Footprint for Installation

Another compelling advantage of water cooled condensing units is their reduced footprint during installation compared to traditional air cooled systems. The compact design allows these units to fit into tight spaces where air-cooled alternatives might struggle or require extensive modifications to the area. This space-saving characteristic makes them particularly appealing for urban environments where every square foot counts.

Moreover, because they rely on water rather than air circulation, there’s no need for extensive ductwork or large outdoor condenser installations that can clutter up valuable real estate outside your facility. This streamlined setup not only enhances aesthetics but also simplifies the overall installation process—saving time and labor costs associated with complex configurations. In short, opting for a water cooled condenser means maximizing usable space while minimizing installation hassles.

Minimal Maintenance Requirements

Since these systems operate using a closed-loop system that relies on circulating chilled water rather than ambient air exposure, there’s significantly less wear and tear on components like filters and coils over time. This durability translates into fewer service calls and lower maintenance costs—a win-win situation for any business owner.

Additionally, because they are less susceptible to dust buildup and environmental contaminants found in outdoor settings, the longevity of key components such as the condenser unit compressor is enhanced significantly when using a water cooled system. Regular checks are still necessary but tend to be less frequent than those required by air-cooled counterparts—allowing staff more time to focus on core business operations instead of worrying about refrigeration issues. Ultimately, investing in a reliable water condensing unit means enjoying peace of mind with minimal disruption from maintenance needs.

Comparing Water Cooled and Air Cooled Systems

Performance Differences

Water cooled condensing units are known for their superior efficiency in heat exchange compared to air cooled systems. By utilizing water as a cooling medium, these units can maintain lower operating temperatures, which translates to better energy performance in commercial refrigeration settings. In contrast, air cooled systems rely on ambient air that can fluctuate in temperature and humidity, potentially leading to reduced efficiency during hot weather.

Moreover, water cooled condensers typically operate more quietly than air cooled units since they are often installed indoors or in less exposed locations. This makes them particularly appealing for businesses concerned about noise pollution affecting their environment or customer experience. Additionally, because they use water for cooling instead of relying solely on outside air, water cooled systems can perform consistently well even in extreme weather conditions.

Installation Considerations

When it comes to installation considerations for water cooled versus air cooled systems, there are several factors at play that could influence your decision-making process. Water cooled condensing units generally require more complex plumbing and infrastructure compared to simpler air cooled installations that only need adequate airflow around the unit. This means that while the initial installation cost may be higher for water cooled systems due to additional piping and equipment requirements, they may offer long-term benefits through increased efficiency.

Another aspect worth noting is space requirements; water cooled units often have a smaller footprint than their air-cooled counterparts because they do not need extensive outdoor venting or clearance space around them. This compact design allows businesses with limited real estate options to maximize available space without sacrificing cooling performance or efficiency. However, proper planning is crucial as you must ensure access to a reliable source of cooling water.

Operational Costs and Lifespan

Operational costs are a vital consideration when comparing water cooled condensing units with air-cooled systems; generally speaking, water-cooled units tend to have lower operational costs over time due to their enhanced energy efficiency capabilities. With reduced energy consumption thanks to better heat exchange processes, businesses can enjoy significant savings on utility bills while maintaining optimal refrigeration conditions within their facilities.

In terms of lifespan, both types of condensing unit compressors can last several years if properly maintained; however, many users report longer lifespans for well-cared-for water-cooled systems due primarily to less strain placed on components like compressors from consistent operating temperatures. Regular maintenance practices for both types should not be overlooked—cleaning coils and checking refrigerant levels are essential tasks regardless of your system type but may differ slightly based on specific requirements unique to each setup.

Ultimately choosing between a water condensed unit or an air-cooled system will depend on various factors including budget constraints and specific operational needs—each has its pros and cons worth weighing carefully before making your final decision.

The Role of the Condenser Unit Compressor

In any water cooled condensing unit, the condenser unit compressor plays a pivotal role in ensuring efficient operation and optimal performance. This component is responsible for compressing refrigerant gas, raising its pressure and temperature before it enters the condenser. Without a well-functioning compressor, the entire refrigeration cycle can falter, leading to inefficiencies and increased operational costs in commercial refrigeration systems.

Types of Compressors Used

The most prevalent include reciprocating compressors, scroll compressors, and screw compressors. Each type has its unique advantages; for instance, scroll compressors are known for their quiet operation and efficiency while screw compressors excel in larger applications due to their robustness and reliability.

Importance in Overall System Efficiency

The efficiency of a water cooled condensing unit largely hinges on the performance of its condenser unit compressor. A high-efficiency compressor not only reduces energy consumption but also enhances cooling capacity, which is crucial for commercial refrigeration applications. By selecting an efficient compressor that matches the specific needs of your water cooled system, businesses can significantly lower operational costs while maximizing cooling output.

How to Choose the Right Compressor

Choosing the right compressor for your water condensing unit involves considering several key factors such as capacity requirements, energy efficiency ratings, and application-specific needs. It's essential to evaluate whether you need a variable speed or fixed speed compressor based on your operational demands; variable speed options provide greater flexibility and efficiency during fluctuating load conditions. Additionally, consulting with experts or manufacturers can help ensure that you select a condenser unit compressor that aligns perfectly with your overall system design.

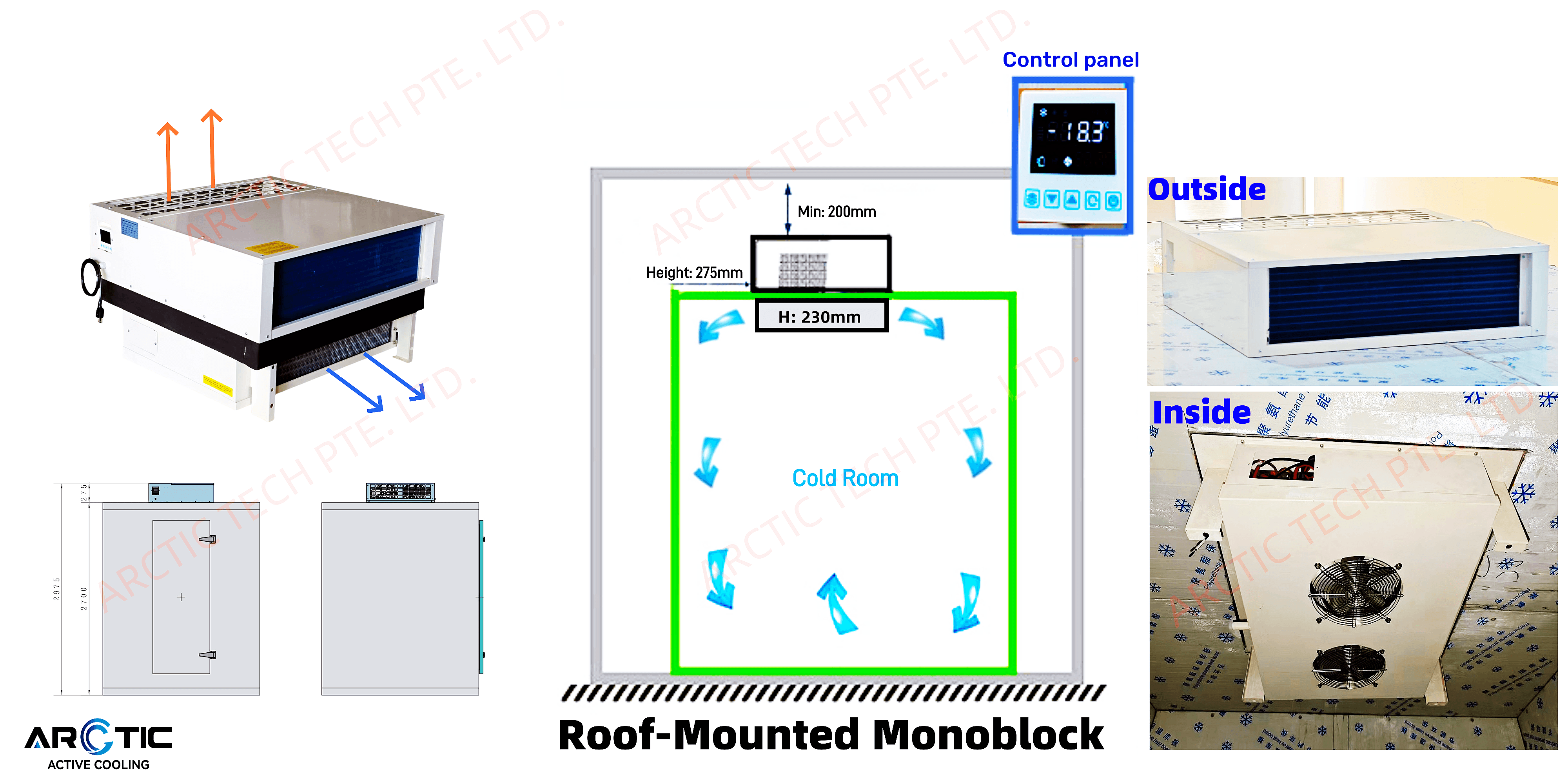

Integrating Arctic Active Cooling Solutions

In the realm of commercial refrigeration, the integration of advanced technologies is pivotal for enhancing efficiency and performance. Arctic Active Cooling Solutions offers innovative products like the DC Condensing Unit, which exemplifies how modern engineering can improve water cooled systems. By focusing on features that optimize functionality, these units are setting new standards in the industry.

Features of Arctic Active Cooling DC Condensing Unit

The Arctic Active Cooling DC Condensing Unit boasts a range of features designed to elevate its performance in various commercial refrigeration applications. Its compact design allows for easy installation in tight spaces, making it an ideal choice for businesses looking to maximize their area without sacrificing cooling capabilities. Additionally, this unit uses advanced materials and technology to ensure durability and reliability, crucial elements for any water cooled condensing unit.

Moreover, the integration of smart technology enables real-time monitoring and adjustments based on operational demands, allowing users to optimize energy consumption effectively. This feature not only enhances the efficiency of water cooled units but also contributes to significant cost savings over time. With a focus on sustainability and performance, Arctic’s condensing unit compressor is engineered to meet the diverse needs of today’s businesses.

Benefits of Direct Expansion Systems

Direct expansion (DX) systems present numerous advantages when integrated with water cooled condensers in commercial refrigeration setups. One significant benefit is their ability to provide precise temperature control while using less energy compared to traditional systems. By employing a direct expansion system alongside a water condensing unit, businesses can achieve optimal cooling without excessive energy expenditure.

Furthermore, DX systems are known for their quick response times when adjusting temperatures based on load changes, ensuring that products remain at ideal temperatures throughout storage and display periods. This responsiveness is particularly vital in industries where product quality depends heavily on consistent cooling conditions—such as food service or pharmaceuticals—making them an excellent match for water cooled units. The synergy between direct expansion technology and water cooled systems leads to improved overall system efficiency.

Simplified Installation Processes

One of the standout features of integrating Arctic Active Cooling solutions into your commercial refrigeration setup is the simplified installation process they offer. With user-friendly designs and straightforward guidelines, contractors can install these units with minimal disruption to business operations—a crucial factor for busy establishments relying on continuous refrigeration services. The combination of well-thought-out engineering and clear instructions makes it easier than ever to incorporate a reliable water chilled solution into existing frameworks.

Additionally, because these units are designed with compactness in mind, they minimize space requirements while maximizing cooling output—a win-win scenario for any business owner looking at space management critically! This ease-of-installation aspect not only reduces labor costs but also shortens downtime during setup—allowing businesses to get back up and running quickly with their new water cooled condensing unit.

In conclusion, integrating Arctic Active Cooling Solutions into your commercial refrigeration strategy brings numerous benefits—from advanced features that enhance efficiency to simplified installation processes that save time and money—all while utilizing effective direct expansion technology within your chosen water cooled units.

Conclusion

In the ever-evolving landscape of commercial refrigeration, water cooled condensing units stand out as a beacon of efficiency and reliability. These systems not only optimize energy consumption but also enhance operational performance across various industries. As businesses increasingly prioritize sustainability, the adoption of water cooled units is likely to surge, making them an excellent choice for modern refrigeration needs.

Maximizing Efficiency with Water Cooled Condensing Units

Water cooled condensing units are designed to maximize efficiency by utilizing water as a cooling medium. This allows for more effective heat exchange compared to air cooled systems, leading to lower energy costs and improved performance in commercial refrigeration applications. By investing in a high-quality water cooled condenser, businesses can reap significant long-term savings while reducing their carbon footprint.

Moreover, the compact nature of water cooled units means they require less space than traditional air cooled alternatives. This is particularly advantageous for urban settings where every square foot counts; therefore, businesses can allocate space more efficiently without compromising on cooling capacity. Additionally, with minimal maintenance requirements associated with these systems, operators can focus on core business functions rather than worrying about frequent repairs or replacements.

Future Trends in Refrigeration Technology

The future of refrigeration technology is leaning heavily towards enhanced energy efficiency and sustainability—two areas where water condensing units excel. Innovations such as smart controls and IoT integration are set to revolutionize how these systems operate and interact with other building management tools. As technology advances, we can expect even greater efficiencies from water cooled systems that will further solidify their place in commercial refrigeration.

Furthermore, the industry is seeing a shift towards environmentally friendly refrigerants that align with global climate goals. Water cooled condensers are well-positioned to adapt to these changes due to their inherent design flexibility and compatibility with various refrigerant types. As regulations tighten around refrigerant usage and emissions standards rise, choosing a water cooled unit could be a proactive step toward compliance.

Why Choose Water Cooled Systems for Your Business

Choosing water cooled systems for your business comes down to several compelling benefits that enhance both performance and cost-efficiency. These units not only provide superior cooling capabilities but also contribute significantly to lowering operational costs over time—an essential factor for any commercial operation looking to maximize profits while minimizing expenses. The reliability of a well-designed condensing unit compressor further ensures that your system operates smoothly under varying load conditions.

Additionally, the reduced footprint required for installation makes water cooled units ideal for facilities where space is at a premium; they pack powerful cooling capabilities into more compact designs than their air-cooled counterparts. With minimal maintenance demands compared to traditional options, businesses can enjoy peace of mind knowing that their investment will remain productive without constant oversight or intervention needed from technicians.

Ultimately, opting for a water condensing unit means embracing innovation while positioning your business at the forefront of efficient refrigeration solutions—a decision that pays off in both immediate performance gains and long-term sustainability goals.