Introduction

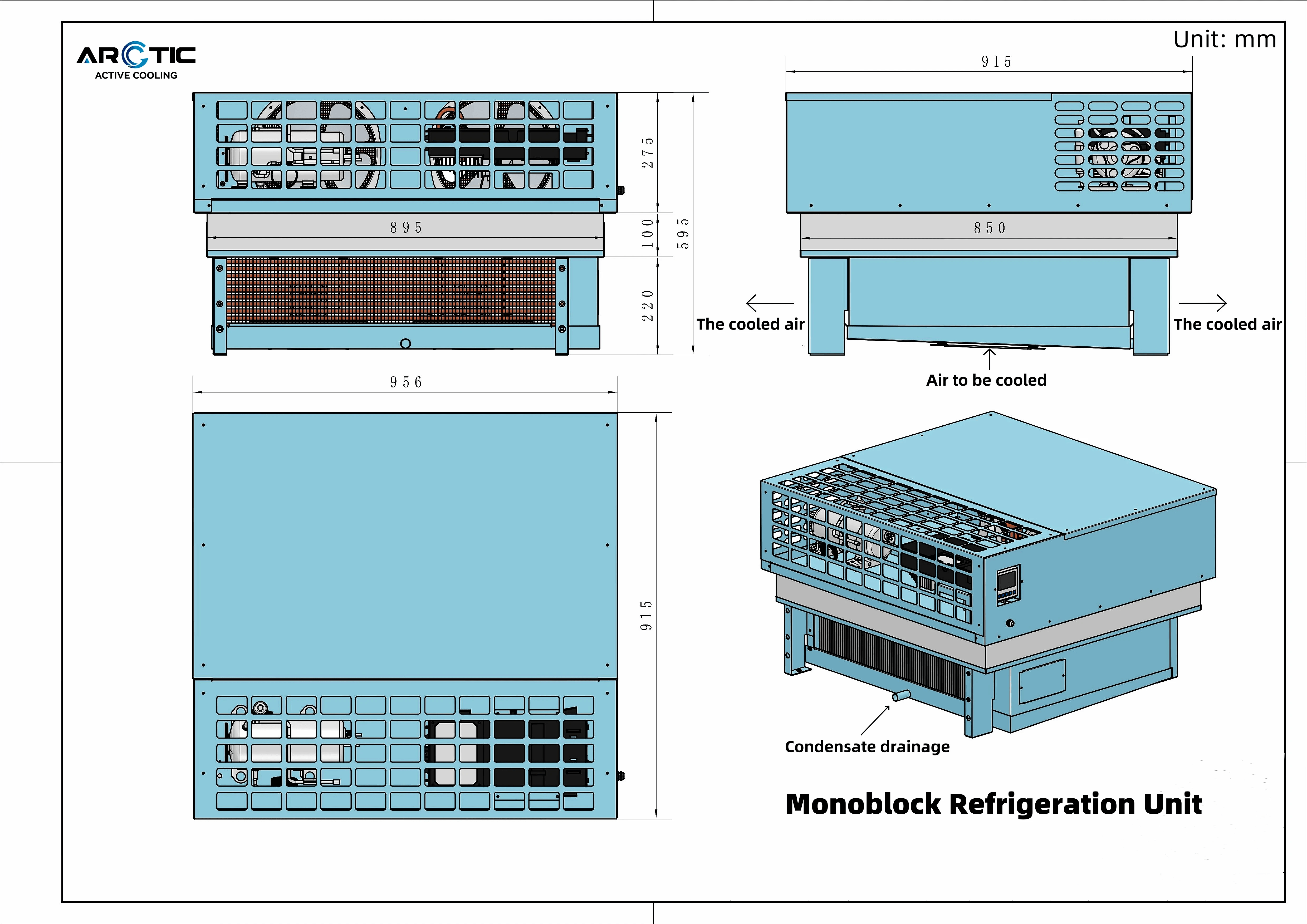

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the world of HVAC, understanding the intricacies of refrigeration systems is essential for both efficiency and effectiveness. At the heart of these systems lies the liquid line in refrigeration systems, a critical component that ensures proper refrigerant flow and temperature regulation. This introduction will explore the essentials of refrigeration systems, highlight common components, and provide an overview of liquid line functions to set the stage for a deeper dive into its significance.

The Essentials of Refrigeration Systems

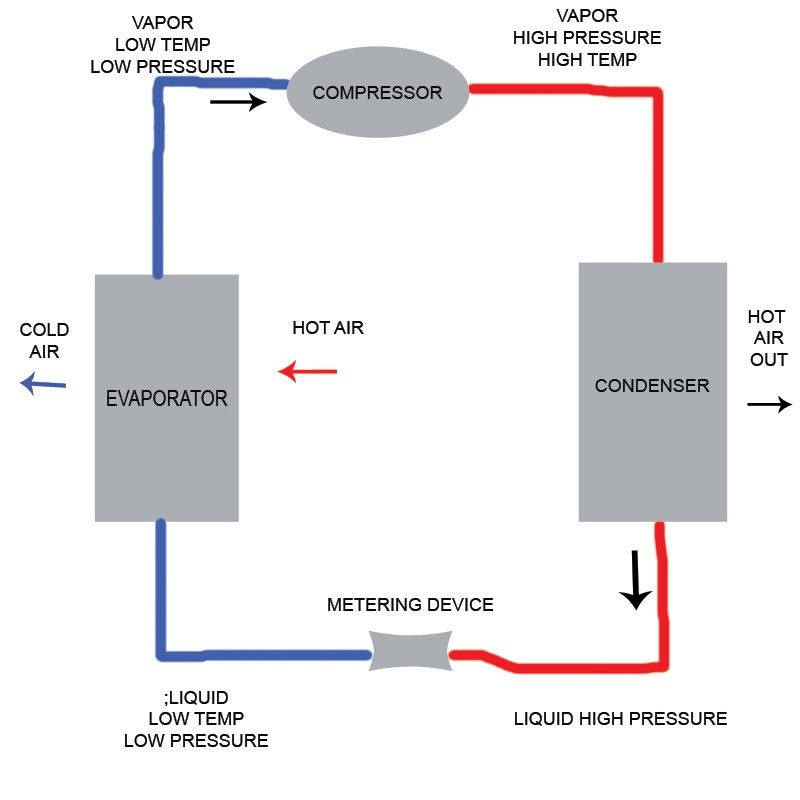

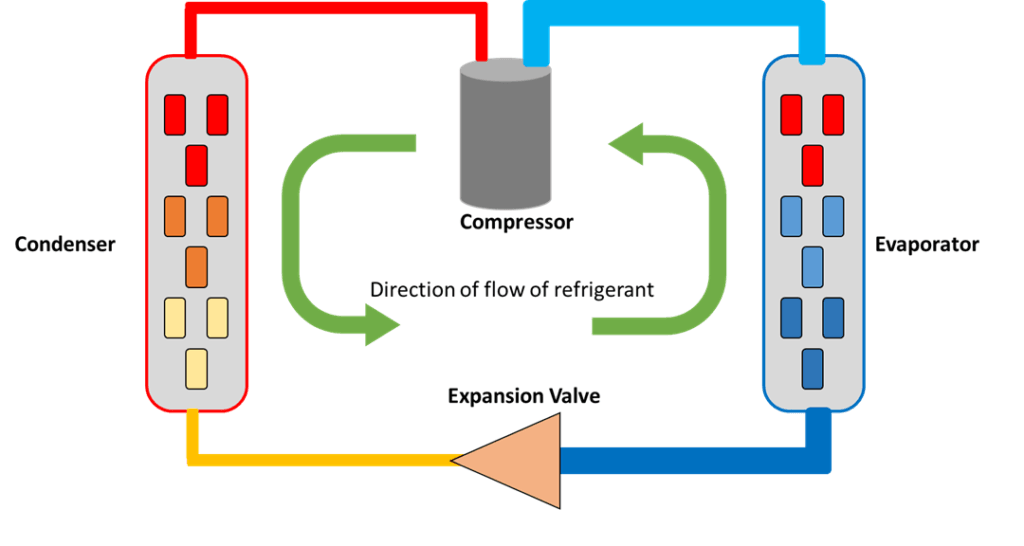

Refrigeration systems operate on fundamental principles that involve heat transfer and phase changes in refrigerants. These systems typically consist of various components working harmoniously to achieve cooling effects, including compressors, evaporators, condensers, and notably, the liquid line in refrigeration systems. Understanding how these elements interact is crucial for optimizing performance and ensuring longevity in HVAC applications.

Common Components of Refrigeration

Among the most vital components are the compressor, which compresses refrigerant gas; the evaporator, where heat absorption occurs; and the condenser that releases heat outside. However, one cannot overlook the importance of lines such as the liquid line and suction line in facilitating refrigerant movement throughout these components. Each plays a distinct role; thus understanding what is the difference between liquid line and suction line becomes paramount for anyone involved with HVAC maintenance or design.

Overview of Liquid Line Functions

The primary function of the liquid line is to transport high-pressure liquid refrigerant from the condenser to various parts within a refrigeration system while maintaining regulated flow rates. It serves as a conduit that connects different system components while ensuring optimal performance through effective heat exchange processes. Additionally, questions like what causes a liquid line to be cold? or what is the purpose of a liquid line receiver? arise frequently among professionals seeking to troubleshoot issues or enhance system efficiency.

Understanding the Liquid Line in Refrigeration System

The liquid line in refrigeration systems plays a crucial role in transporting refrigerant from the condenser to the expansion device. This line is responsible for carrying high-pressure liquid refrigerant, which is essential for maintaining efficient cooling cycles. Understanding the significance of this component can help enhance system performance and longevity.

Definition and Role of Liquid Line

The liquid line is a key pathway within the refrigeration system that transports refrigerant after it has been condensed into a liquid state. It connects the condenser to various components, ensuring that refrigerant flows smoothly and efficiently throughout the system. Without a properly functioning liquid line, cooling efficiency would plummet, causing potential damage to other components as well.

How Liquid Line Connects to Other Components

In a typical refrigeration setup, the liquid line connects directly to several critical components, including the receiver, expansion valve, and evaporator coil. Each connection plays a unique role in regulating refrigerant flow and pressure throughout the system. A well-integrated liquid line not only facilitates effective heat exchange but also ensures that all parts operate harmoniously for optimal performance.

Importance of Liquid Flow Regulation

Regulating flow within the liquid line is vital for maintaining desired pressures and temperatures throughout the refrigeration cycle. If flow is too high or too low, it can lead to inefficiencies or even catastrophic failures in other parts of the system—this includes understanding what causes a liquid line to be cold or hot gas lines' interactions with it. Proper regulation helps ensure that each component receives exactly what it needs for peak performance while minimizing energy consumption.

What is the Difference Between Liquid Line and Suction Line?

In the realm of refrigeration systems, understanding the distinctions between various lines is crucial for optimal performance. Among these, the liquid line and suction line play pivotal roles, each serving unique functions that contribute to the overall efficiency of the system. Grasping what is the difference between liquid line and suction line? can illuminate how these components interact within a cooling cycle.

Functional Distinctions between Lines

The liquid line in refrigeration systems primarily transports refrigerant in its liquid state from the condenser to various components like expansion valves and evaporators. Conversely, the suction line carries refrigerant vapor back to the compressor after it has absorbed heat from its surroundings in the evaporator. This fundamental difference in function underscores how both lines work together to facilitate heat exchange while maintaining system pressure.

Understanding these functional distinctions helps identify issues when they arise; for instance, a malfunctioning suction line can lead to inadequate cooling performance or compressor failure. Moreover, recognizing their roles also aids technicians in troubleshooting and maintaining HVAC systems effectively. Thus, knowing what is the difference between liquid line and suction line? not only enhances comprehension but also improves operational reliability.

Temperature and Pressure Variations

Temperature and pressure variations are significant aspects that differentiate these two lines within a refrigeration system. The liquid line typically operates under high pressure as it carries refrigerant from the condenser after it has been cooled down, while temperatures remain relatively low compared to other components of the system. In contrast, the suction line experiences lower pressure due to its role in returning vaporized refrigerant at higher temperatures back to the compressor.

These variations are essential for maintaining efficient operation; if one of these lines malfunctions or experiences blockages, it can lead to overheating or excessive cooling issues throughout the entire system. Technicians must monitor these parameters closely during maintenance checks because deviations could indicate underlying problems that need addressing immediately. In summary, understanding temperature and pressure differences further clarifies what is the difference between liquid line and suction line?

Impact on Overall System Efficiency

The impact of both lines on overall system efficiency cannot be overstated; improper functioning of either can result in significant energy losses or operational failures within an HVAC unit. A well-maintained liquid line ensures optimal flow of refrigerant under high pressure while minimizing energy consumption during cooling cycles—this directly correlates with reduced operational costs for businesses relying on climate control solutions like those provided by ARCTIC.

On a broader scale, comprehending what is involved with each component allows engineers and technicians to design more efficient systems that meet specific customer needs across diverse industries—from medical facilities requiring precise temperature management to electric vehicles demanding compact cooling solutions. Therefore, exploring how both lines affect overall efficiency not only answers what is the purpose of a liquid line receiver? but also highlights innovative approaches toward enhancing HVAC performance through companies like ARCTIC.

What is the Difference Between Liquid Line and Hot Gas Line?

In refrigeration systems, understanding the distinction between the liquid line and hot gas line is essential for optimal performance. While both lines are critical components of the overall system, they serve very different functions that impact efficiency and design. This section will explore these differences in detail, focusing on their roles, pressure and temperature characteristics, and implications for system design.

Understanding Hot Gas Line Functions

The hot gas line carries refrigerant vapor from the compressor to various components within the refrigeration system. This vapor is at a high temperature and pressure after being compressed, making it crucial for transferring heat away from the evaporator coil. Essentially, while the liquid line in refrigeration systems is responsible for delivering refrigerant in liquid form to the expansion valve or receiver, the hot gas line plays a pivotal role in returning heat to maintain operational efficiency.

Hot gas lines can also be involved in defrost cycles for certain types of systems by transferring heat back through evaporators when needed. This functionality showcases their importance not just in regular operation but also during maintenance processes like defrosting. Understanding these functions helps clarify what is the difference between liquid line and hot gas line—one focuses on cooling through liquid transport while the other manages heating via vapor movement.

Comparisons in Pressure and Temperature

When comparing pressure and temperature between these two lines, significant differences emerge that underscore their distinct roles within a refrigeration system. The liquid line typically operates at lower pressures compared to its counterpart; this allows it to transport refrigerant efficiently without excessive energy consumption. In contrast, hot gas lines operate under high pressure due to compression processes; this high-pressure vapor must be managed carefully to prevent leaks or inefficiencies.

Temperature variations further illustrate these distinctions: while liquids flowing through the liquid line are cooler as they absorb heat from their surroundings, gases traveling through hot gas lines are significantly warmer due to compression heating effects. These contrasting conditions highlight why an understanding of what is the difference between liquid line and hot gas line is vital for anyone working with HVAC systems—mismanagement can lead to inefficiencies or even system failure.

Implications for System Design and Efficiency

The differences between these two lines have direct implications for system design considerations as well as overall efficiency in refrigeration applications. Engineers must account for varying materials that can withstand different pressures when designing both lines; using appropriate insulation techniques becomes crucial especially for those dealing with high-temperature gases versus cooler liquids.

Moreover, ensuring proper routing of both lines minimizes energy loss; an efficient layout reduces unnecessary bends or long runs which could compromise performance over time—thus impacting what causes a liquid line to be cold due to inefficient heat exchange processes elsewhere in the system.

Finally, understanding how these two components interact helps optimize overall HVAC performance by ensuring each part fulfills its designated role effectively—ultimately enhancing user satisfaction with reliable cooling solutions tailored by innovative companies like ARCTIC that specialize in custom thermal solutions across various industries.

What is the Purpose of a Liquid Line Receiver?

The liquid line receiver plays a crucial role in the overall efficiency and functionality of the liquid line in refrigeration systems. Acting as a storage vessel, it ensures that refrigerant is available in a consistent state for optimal system operation. Understanding the purpose of a liquid line receiver helps clarify its importance in maintaining balance within the refrigeration cycle.

Functionality and Importance

The primary function of a liquid line receiver is to collect and store excess refrigerant from the condenser before it flows into other components of the system. This storage capability allows for fluctuations in refrigerant flow, ensuring that there’s always enough refrigerant available to meet demand, especially during peak operational times. Additionally, by providing this buffer, it helps prevent issues such as flooding or starving components downstream, which can lead to inefficiencies or even damage.

In essence, without a properly functioning liquid line receiver, you might find yourself asking: what is the difference between liquid line and suction line? The answer lies in their roles; while one stores and regulates refrigerant flow, the other manages vaporized refrigerant returning to the compressor. Thus, understanding these distinctions aids in appreciating how critical each component is within an HVAC system.

Role in Liquid Line Efficiency

A well-designed liquid line receiver enhances overall system efficiency by ensuring that only high-pressure liquid refrigerant enters the expansion device at optimal conditions. When operating efficiently, it minimizes pressure drops and maintains constant flow rates that are essential for effective heat exchange processes throughout your refrigeration setup. In turn, this contributes to better energy consumption rates—something every facility manager should keep an eye on!

Furthermore, addressing common questions like what causes a liquid line to be cold becomes easier when you consider how effectively a receiver manages temperature changes and pressure variations through its design features. By preventing backflow or vaporization of refrigerants at inappropriate times, receivers help maintain ideal conditions throughout various stages of cooling processes.

Connection to Refrigeration Cycle

The connection between a liquid line receiver and the refrigeration cycle cannot be overstated; it serves as an integral link between multiple components working together harmoniously. Positioned right after the condenser within this cycle, it acts as an intermediary that prepares refrigerants for entry into expansion devices like thermal expansion valves (TXVs).

This positioning emphasizes why understanding what is the purpose of a liquid line receiver matters—it directly influences how effectively your entire cooling system operates! Moreover, knowing how this component interacts with others helps clarify further distinctions such as what is the difference between liquid line and hot gas line? Each plays unique roles but must work cohesively for maximum performance.

In conclusion, recognizing these connections not only highlights importance but also encourages proper maintenance practices tailored towards enhancing longevity across all equipment involved within any HVAC setup—particularly those utilizing advanced solutions from ARCTIC!

What Causes a Liquid Line to Be Cold?

When discussing the liquid line in refrigeration systems, one may wonder why it can sometimes feel cold to the touch. This phenomenon is primarily influenced by several factors, including the refrigerant's pressure and temperature as it travels through the system. Additionally, heat exchange processes play a significant role in determining the temperature of the liquid line.

Factors Affecting Liquid Line Temperature

The temperature of the liquid line in refrigeration systems is affected by multiple variables, including ambient temperature and system load. When the refrigerant leaves the condenser and enters the liquid line, its state can vary based on how effectively heat has been removed during condensation. Moreover, if there is insufficient refrigerant flow or if there are blockages within the line, this can lead to lower temperatures due to reduced heat absorption.

Another key factor influencing liquid line temperature is pressure changes throughout the system. High-pressure refrigerants tend to have higher boiling points; thus, any drop in pressure can result in a cooler liquid state as it transitions from high-pressure areas to lower-pressure zones. Understanding these factors helps clarify what causes a liquid line to be cold and emphasizes its importance within HVAC systems.

Heat Exchange and Refrigeration Principles

Heat exchange principles are at play when considering why a liquid line becomes cold in refrigeration systems. The process of heat transfer occurs when warm air from inside a building comes into contact with cooler surfaces of evaporators or condensers; this interaction allows for effective cooling of indoor spaces. In essence, as refrigerants absorb heat from their surroundings during evaporation or condensation phases, they significantly impact temperatures along various lines.

Moreover, it's essential to understand how these principles relate back to questions like What is the difference between liquid line and suction line? The suction line carries low-pressure vapor back to the compressor while absorbing heat; conversely, colder temperatures characterize the liquid line post-condensation phase before entering expansion devices or evaporators.

Troubleshooting Cold Liquid Line Issues

Troubleshooting issues related to a cold liquid line involves identifying potential problems that could affect overall efficiency within refrigeration systems. If you notice that your liquid line feels excessively cold or even frosty at times, it might indicate an issue such as overcharging of refrigerant or malfunctioning expansion devices that disrupt normal flow patterns.

Additionally, understanding What is the purpose of a liquid line receiver? becomes crucial here since this component regulates refrigerant flow and ensures proper functioning throughout various stages of cooling cycles—any malfunction could lead directly back to unusual temperatures in your lines.

In summary, recognizing what causes a liquid line to be cold enhances our understanding of HVAC systems' operational dynamics while highlighting essential maintenance practices required for optimal performance.

Conclusion

In conclusion, the liquid line in refrigeration systems plays a pivotal role in ensuring efficient operation and effective cooling. It is responsible for transporting refrigerant from the condenser to the expansion device, facilitating heat exchange and maintaining optimal temperatures throughout the system. Understanding key aspects such as what is the difference between liquid line and suction line, as well as what is the purpose of a liquid line receiver, can greatly enhance our grasp of refrigeration mechanics.

Key Functions of Liquid Line in Refrigeration

The primary function of the liquid line in refrigeration systems is to carry high-pressure refrigerant in its liquid state from the condenser to various components like expansion valves or receivers. This process is crucial for maintaining proper pressure levels and ensuring that refrigerant transitions smoothly into its gaseous form during evaporation. Additionally, understanding the importance of liquid line in HVAC applications underscores how it contributes to overall system efficiency and performance.

The Importance of Proper Maintenance

Proper maintenance of the liquid line is essential to prevent issues such as blockages or leaks that could disrupt refrigerant flow. Regular inspections can help identify problems early on, ensuring that questions like what causes a liquid line to be cold are addressed before they escalate into costly repairs. A well-maintained system not only enhances efficiency but also extends equipment lifespan, leading to better long-term savings.

Exploring Innovative Solutions with ARCTIC

ARCTIC stands out as a leader in thermal solutions by providing custom cooling systems tailored for various industries including medical, aerospace, and automation sectors. Their innovative designs focus on enhancing efficiency while addressing specific customer needs—whether it's small DC air conditioners or compact water chillers. As we explore advancements in technology, ARCTIC continues to redefine standards for reliability and performance within refrigeration systems.