Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the fast-paced world of food service and storage, the significance of proper food cold room storage cannot be overstated. A well-maintained cold room is essential not only for preserving the quality and safety of perishable goods but also for ensuring compliance with health regulations. By implementing effective cooling techniques and investing in the right equipment, businesses can enhance their operational efficiency while minimizing waste.

Importance of Proper Food Cold Room Storage

Proper food cold room storage plays a critical role in maintaining the freshness and safety of food items. Without appropriate temperature control, perishable goods can spoil quickly, leading to financial loss and potential health hazards. Commercial cold rooms are designed to provide a stable environment that prevents bacterial growth and preserves the integrity of various food products.

Essential Techniques for Effective Cooling

To achieve optimal cooling in a food cold room, several key techniques must be employed. First, maintaining the correct cold room freezer temperature is crucial; typically, this should be set between 32°F (0°C) and 41°F (5°C) depending on the type of food stored. Additionally, utilizing efficient airflow systems ensures that all areas within the cold room are evenly cooled, preventing hot spots that could compromise food safety.

Choosing the Right Cold Room Equipment

Selecting appropriate equipment is vital when setting up a commercial cold room or upgrading existing facilities. Factors such as cold room freezer price, energy efficiency ratings, and capacity should all be considered to ensure long-term benefits for your business. Investing in high-quality units like Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit can provide unparalleled performance while meeting modern cooling demands efficiently.

Understanding Food Cold Room Basics

Food cold rooms are essential components in the food storage and preservation industry. Designed to maintain optimal temperatures, these spaces help prolong the shelf life of perishable goods while ensuring food safety. Understanding the fundamentals of food cold rooms is crucial for anyone involved in commercial food handling.

What is a Food Cold Room?

A food cold room is a temperature-controlled environment specifically designed for storing various types of perishable foods, including meats, dairy products, and fresh produce. These facilities can be found in supermarkets, restaurants, and warehouses where large quantities of food need to be stored safely. Unlike standard refrigerators or freezers, commercial cold rooms offer larger capacities and can maintain specific temperature ranges tailored to different types of food items.

Importance of Temperature Control

Temperature control in a food cold room is vital for preventing spoilage and ensuring the safety of stored items. Maintaining appropriate cold room freezer temperatures helps inhibit bacterial growth and preserves the quality of food products over time. For instance, different foods require specific temperature settings; while some may thrive at 32°F (0°C), others may need colder conditions closer to -10°F (-23°C) for optimal preservation.

Common Food Storage Guidelines

When utilizing a cold room chiller unit, adhering to common storage guidelines is essential for maintaining food quality and safety. First, always store raw meats on lower shelves to prevent cross-contamination with other foods; this practice helps keep your entire inventory safe from harmful bacteria. Additionally, regularly check expiration dates and implement a first-in-first-out (FIFO) system to ensure that older products are used before newer ones—a simple yet effective way to manage stock in your commercial cold rooms.

Best Practices for Food Cold Room Organization

Organizing a food cold room is not just about aesthetics; it’s crucial for maintaining food safety and efficiency. A well-organized space ensures that food items are easily accessible and stored under optimal conditions, which directly impacts their quality and longevity. By following best practices in organization, businesses can maximize the use of their commercial cold rooms while adhering to safety standards.

Zoning Your Cold Room Effectively

Zoning your food cold room involves designating specific areas for different types of products, which enhances both efficiency and safety. For instance, raw meats should be stored in a separate zone from ready-to-eat foods to prevent cross-contamination. Additionally, utilizing temperature zones within the cold room freezer can help maintain appropriate cold room freezer temperatures for various items, ensuring that everything from dairy to produce stays fresh longer.

Creating distinct zones also aids in inventory management; by knowing where each type of product is located, staff can quickly find what they need without rummaging through mixed items. This not only speeds up operations but also minimizes the time doors are open—helping to maintain consistent temperatures throughout the cold room chiller unit. Ultimately, effective zoning leads to better organization and enhanced food safety.

Labeling and Inventory Management

Proper labeling is essential in any food storage environment, especially in a busy commercial cold room where multiple products are stored simultaneously. Each item should be clearly labeled with its name, storage date, and expiration date to facilitate easy identification and rotation—this practice helps prevent spoilage and waste. Integrating an efficient inventory management system will keep track of stock levels while ensuring that older products are used first (FIFO method).

Incorporating technology like barcode scanners or inventory software can streamline this process even further by providing real-time updates on stock levels within your cold room freezer. Regular audits of your inventory will help identify any discrepancies or potential issues before they escalate into costly problems. With organized labeling and effective inventory management strategies in place, you’ll create a more efficient workflow that keeps your food safe.

Utilizing Vertical Space for Storage

When it comes to maximizing storage capacity in a food cold room, vertical space is often overlooked but incredibly valuable. Installing shelving units or racks allows you to take advantage of the height available within the space rather than just relying on floor area alone—this is particularly beneficial when dealing with larger commercial cold rooms where every inch counts! By stacking items vertically, you not only increase storage capacity but also improve air circulation around your products.

Additionally, using clear bins or containers on shelves makes it easier to see what you have at a glance while keeping similar items grouped together; this reduces clutter and simplifies restocking processes within your cold room freezer or chiller unit. Remember that proper airflow is key; ensure that nothing blocks vents or fans so that all areas maintain consistent temperatures critical for food preservation. Utilizing vertical space effectively transforms how you use your storage area while enhancing overall efficiency.

Advanced Cooling Solutions for Food Cold Rooms

In the realm of food cold room storage, advanced cooling solutions are essential for maintaining optimal conditions and ensuring food safety. Innovations like Arctic Active Cooling systems and top-mounted monoblock refrigeration units have revolutionized commercial cold rooms. These technologies not only enhance performance but also contribute to sustainability and energy efficiency.

Benefits of Arctic Active Cooling Systems

Arctic Active Cooling systems are a game changer for food cold rooms, offering unparalleled efficiency that ensures your products remain at the ideal temperature. With their innovative design tailored for commercial refrigerators and freezers, these systems excel in maintaining consistent cold room freezer temperatures, crucial for preserving perishable items. Moreover, their reliability minimizes downtime, allowing businesses to operate smoothly without worrying about spoilage.

These advanced cooling solutions are particularly beneficial in high-demand environments where temperature fluctuations can compromise food quality. By investing in an Arctic Active Cooling system, businesses can enjoy peace of mind knowing they have a robust solution that meets the rigorous demands of modern food storage. Plus, with competitive cold room freezer prices available on the market today, upgrading your cooling system has never been more feasible.

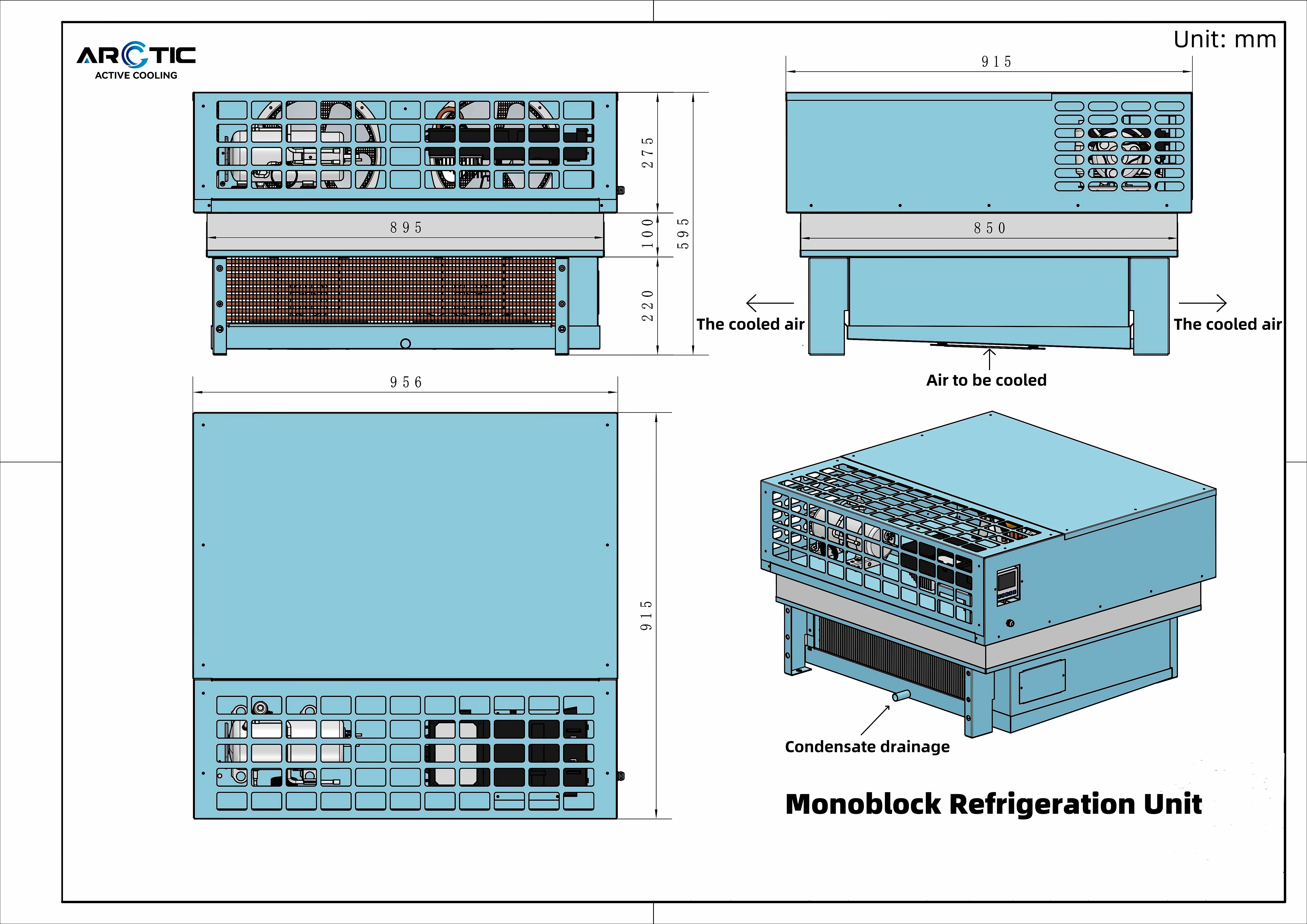

Features of Top-Mounted Monoblock Refrigeration Units

Top-mounted monoblock refrigeration units are another fantastic option for enhancing your food cold room setup. These all-in-one units simplify installation and maintenance while providing powerful cooling capabilities tailored specifically for commercial applications. Ideal for both cold room chiller units and freezers alike, they ensure that every inch of your space is utilized effectively—keeping everything from fruits to proteins at safe temperatures.

One standout feature is their compact design which maximizes vertical space in your cold room while minimizing footprint issues associated with traditional systems. This makes them perfect for smaller facilities or those looking to optimize existing setups without sacrificing performance or storage capacity. Additionally, these units come equipped with user-friendly controls that allow you to monitor and adjust temperatures effortlessly.

Sustainability and Energy Efficiency

Sustainability is becoming increasingly important in today's business landscape, especially within the food industry where waste reduction is paramount. Advanced cooling solutions like Arctic Active Cooling systems and top-mounted refrigeration units are designed with energy efficiency in mind—helping businesses lower their carbon footprint while saving on operational costs associated with electricity consumption.

By utilizing cutting-edge technology that minimizes energy use without compromising performance, these systems help create a more sustainable approach to food storage in commercial settings. Furthermore, many modern cold room freezer models incorporate features such as smart sensors that optimize energy usage based on real-time conditions within the unit—a win-win situation! Investing in these sustainable solutions not only benefits your bottom line but also contributes positively to environmental stewardship.

Routine Maintenance for Optimal Performance

Maintaining a food cold room is crucial for ensuring the safety and quality of stored items. Regular maintenance not only prolongs the life of your equipment but also prevents costly breakdowns and ensures compliance with health standards. By implementing a routine maintenance schedule, you can enhance the efficiency of your commercial cold rooms and keep operations running smoothly.

Daily Checks and Balances

Daily checks are essential for monitoring the performance of your cold room freezer or chiller unit. Start by verifying that the cold room freezer temperature is within the recommended range, typically between -18°C to 0°C depending on what you're storing. Additionally, inspect door seals for any signs of wear or damage, as compromised seals can lead to temperature fluctuations and increased energy costs.

Regularly check the functionality of digital displays and alarms in your commercial cold rooms to ensure they are operating correctly. If any discrepancies arise, addressing them promptly can prevent larger issues down the line. Keeping a log of daily checks creates accountability and helps track trends that could indicate potential problems with your equipment.

Cleaning Guidelines for Refrigeration Units

A clean environment is vital for optimal performance in any food cold room setting. Begin by regularly cleaning condenser coils in your cold room chiller unit; dirty coils can hinder efficiency and lead to higher energy bills over time. Use a soft brush or vacuum attachment to remove dust and debris buildup from these critical components.

Don’t forget about interior cleaning! Wipe down shelves, walls, and floors using food-safe cleaning solutions to eliminate spills or contaminants that could affect food safety standards. Regularly scheduled deep cleans not only maintain hygiene but also extend the lifespan of your commercial cold rooms.

Troubleshooting Common Issues

Even with diligent maintenance practices, issues may occasionally arise within your food cold room system. One common problem is inconsistent temperature readings; if you notice fluctuations outside acceptable ranges, check door seals first before diving deeper into mechanical issues like refrigerant levels or compressor function.

If ice buildup occurs in your cold room freezer or chiller unit, it might be due to high humidity levels or improper airflow; resolving these factors can help restore normal operation quickly. For more complex problems such as unusual noises or persistent error codes on digital displays, consulting professionals who specialize in refrigeration solutions may be necessary for effective troubleshooting.

Food Safety Standards and Regulations

Maintaining food safety standards within your food cold room is essential for ensuring the quality and safety of stored items. This involves adhering to established guidelines and regulations that help prevent foodborne illnesses and maintain product integrity. Understanding these standards not only protects consumers but also enhances the reputation of your business.

Understanding HACCP Principles

The Hazard Analysis Critical Control Point (HACCP) system is a proactive approach to food safety that identifies potential hazards in the storage process, particularly in environments like commercial cold rooms. By implementing HACCP principles, businesses can establish critical control points where temperature monitoring becomes crucial, especially for cold room freezer temperatures. Regularly assessing risks associated with various foods helps ensure that your cold room chiller unit operates within safe parameters, ultimately safeguarding public health.

Compliance with Health Department Regulations

Compliance with health department regulations is non-negotiable for any establishment utilizing a food cold room. These regulations often specify acceptable temperature ranges for different types of food storage, including those maintained in cold room freezers or chillers. Failure to comply can result in fines or even closure, making it vital to invest in reliable refrigeration solutions that meet these standards while maintaining optimal performance.

Importance of Regular Audits

Conducting regular audits of your food cold room is vital for ensuring ongoing compliance with HACCP principles and health department regulations. These audits should assess both the functionality of equipment, like your cold room freezer unit, and adherence to proper storage practices. By routinely evaluating operations, businesses can identify areas for improvement while reinforcing their commitment to food safety—ultimately enhancing customer trust.

Conclusion

In conclusion, proper food cold room storage is crucial for maintaining food safety and quality. The advantages of effective cold storage extend beyond just preserving perishables; they encompass enhanced operational efficiency and compliance with health regulations. Investing in reliable refrigeration solutions not only safeguards your inventory but also contributes to long-term sustainability.

Key Advantages of Proper Cold Storage

The key advantages of proper cold storage are manifold, starting with the preservation of food quality over time. By utilizing a well-maintained cold room freezer, businesses can significantly reduce spoilage and waste, ultimately saving money in the long run. Additionally, maintaining appropriate cold room freezer temperatures ensures that food remains safe for consumption, aligning with health standards and enhancing customer satisfaction.

Investment in Reliable Refrigeration Solutions

Investing in reliable refrigeration solutions is essential for any business that handles perishable goods. Commercial cold rooms equipped with advanced technology like Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit provide unparalleled efficiency and reliability while keeping operational costs low. When considering the cold room freezer price, it’s vital to look beyond just initial costs and evaluate the long-term benefits of energy-efficient systems that promise durability and performance.

Future Trends in Food Cold Room Technology

The future trends in food cold room technology are leaning towards increased automation and smarter monitoring systems. With advancements such as IoT integration, businesses can expect real-time tracking of temperature fluctuations within their cold room chiller units, ensuring optimal conditions at all times. As sustainability becomes a priority, innovations will likely focus on reducing energy consumption while enhancing cooling efficiency—making modern commercial cold rooms more eco-friendly than ever before.