Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the world of cooling technologies, coaxial water cooled condensers stand out for their innovative design and efficient performance. These systems, which utilize a unique coaxial configuration, are essential in various applications ranging from industrial processes to commercial refrigeration. Understanding their functionality and benefits can significantly impact your choice when you decide to shop coaxial water cooled condensers.

Overview of Coaxial Water Cooled Condensers

Coaxial water cooled condensers are specialized heat exchangers that use a dual-tube system to maximize cooling efficiency. The inner tube carries the refrigerant while the outer tube circulates cooling water, allowing for effective heat transfer in a compact design. This configuration is particularly advantageous in applications where space is limited or where high thermal performance is required.

Importance of Selecting the Right Type

Choosing the right type of condenser can make or break your cooling system's efficiency and reliability. With various designs available, including Coaxial Tube-in-Tube Water-Cooled Condensers and Water Cooled Condenser Coaxial Coils, it’s crucial to assess your specific needs before making a decision. The right selection ensures optimal performance, longevity, and cost-effectiveness in your operations.

Benefits of Using Coaxial Designs

The benefits of using coaxial designs go beyond mere space-saving; they also offer superior thermal performance and ease of maintenance. Their efficient heat exchange capabilities result in lower energy consumption while maintaining high cooling capacities—ideal for modern industrial demands. Additionally, these systems often come with advanced features that enhance user control and integration with existing machinery, making them an attractive choice for many industries.

Understanding Coaxial Water Cooled Condensers

Coaxial water cooled condensers are innovative cooling devices designed to efficiently transfer heat from a refrigerant to water. These systems utilize a unique coaxial design, where one tube is situated inside another, allowing for optimal heat exchange between the two fluids. By understanding their definition and functionality, you can appreciate the importance of selecting the right coaxial water cooled condenser for your specific needs.

Definition and Functionality

A coaxial water cooled condenser consists of two concentric tubes that facilitate the cooling process by allowing hot refrigerant gas to flow through the inner tube while cold water circulates in the outer tube. This design maximizes surface area contact between the two fluids, ensuring efficient heat transfer and minimizing energy loss. The primary function of this type of condenser is to convert vaporized refrigerant back into liquid form through effective cooling, thus playing a crucial role in refrigeration and air conditioning systems.

How They Work in Cooling Systems

In cooling systems, a coaxial water cooled condenser operates by receiving hot refrigerant gas from the compressor. As this gas travels through the inner tube, it releases its heat to the cold water flowing around it in the outer tube. This process not only cools down the refrigerant but also raises the temperature of the circulating water, which can then be used for other heating applications or expelled safely into drainage systems.

Applications in Various Industries

Coaxial water cooled condensers find applications across multiple industries due to their efficiency and compact design. In commercial refrigeration setups, such as those found in supermarkets or restaurants, these condensers help maintain optimal temperatures for food preservation while saving energy costs. Additionally, they are commonly used in industrial processes that require precise temperature control—think chemical manufacturing or HVAC systems—making them versatile components worth considering when you shop coaxial water cooled condensers.

Types of Coaxial Water Cooled Condensers

Coaxial Tube-in-Tube Water-Cooled Condenser

The Coaxial Tube-in-Tube Water-Cooled Condenser is a popular choice due to its efficient heat exchange capabilities. In this design, one tube is situated inside another, allowing for a continuous flow of coolant that maximizes surface area contact between the fluids. This setup not only enhances thermal performance but also minimizes pressure drop, making it ideal for high-efficiency applications.

This type of coaxial water cooled condenser is commonly used in industrial processes where space is limited but cooling demands remain high. The compact design allows it to fit into tight spaces while still providing effective cooling solutions. Additionally, its robust construction ensures durability and reliability over time, which is essential for long-term operations.

For those looking to shop coaxial water cooled condensers, this model often stands out due to its performance metrics and versatility across various applications—from HVAC systems to refrigeration units.

Water Cooled Condenser Coaxial Coil

Another noteworthy option is the Water Cooled Condenser Coaxial Coil, which features a coiled design that optimizes fluid dynamics within the system. This configuration allows for a more uniform distribution of fluid flow compared to traditional designs, leading to improved efficiency in heat transfer processes. The coils are typically designed with materials that enhance thermal conductivity while also resisting corrosion.

The unique structure of this condenser makes it suitable for both commercial and industrial settings where effective cooling solutions are crucial. Its adaptability means it can be integrated into existing systems without extensive modifications or additional space requirements—ideal for businesses looking to upgrade their cooling capabilities without overhauling their infrastructure.

When considering options like Arctic Active Cooling's Mini Water Chiller—which incorporates advanced technology such as a high-efficient refrigeration mini compressor—this type of water cooled condenser can be an excellent match due to its compatibility with sophisticated control systems.

Comparison of Different Design Variations

When comparing these two types of coaxial water cooled condensers—Coaxial Tube-in-Tube vs. Water Cooled Condenser Coaxial Coil—it's essential to evaluate their specific advantages based on your needs. The tube-in-tube design excels in compactness and ease of installation while maintaining high efficiency levels; however, it may require more maintenance if not properly managed over time.

On the other hand, the coaxial coil offers superior fluid flow dynamics and can adapt easily within existing systems but may take up slightly more space depending on the installation context. Ultimately, choosing between these variations will depend on factors like available space, required efficiency levels, and specific application needs within your industry.

Whether you're looking at Arctic Active Cooling's innovative solutions or exploring other brands in the market, understanding these differences will empower you as you navigate your options among coaxial water cooled condensers.

Key Features to Consider

When selecting a coaxial water cooled condenser, several key features can significantly influence your decision-making process. Understanding efficiency and performance metrics, material choices for durability, and size and installation flexibility is crucial. These factors not only affect the operational effectiveness of the condenser but also its longevity and adaptability in various applications.

Efficiency and Performance Metrics

Efficiency is paramount when considering a coaxial water cooled condenser. Look for models that boast high thermal transfer rates, as this directly impacts overall cooling performance. For instance, the Coaxial Tube-in-Tube Water-Cooled Condenser design is known for its superior efficiency due to its unique structure that maximizes heat exchange while minimizing pressure drops.

Performance metrics such as cooling capacity, energy consumption, and flow rates are essential indicators of how well a water cooled condenser will perform in your specific application. When you Shop Coaxial Water Cooled Condensers, pay attention to these figures; they can save you money on energy bills while ensuring optimal operation. Additionally, consider models with adjustable flow rates or variable speed pumps to further enhance performance based on your needs.

Material Choices for Durability

The materials used in constructing a coaxial water cooled condenser play a significant role in its durability and lifespan. Common materials include stainless steel and copper; both offer excellent corrosion resistance which is vital in maintaining performance over time. Selecting a Water Cooled Condenser Coaxial Coil made from high-quality materials ensures it can withstand harsh operating conditions without compromising efficiency.

Moreover, consider the environmental factors where the condenser will be installed—such as humidity levels or exposure to chemicals—as these can affect material choice significantly. Investing in durable materials not only means fewer replacements but also translates into reduced maintenance costs over time. Remember that quality construction can make all the difference when it comes to long-term reliability.

Size and Installation Flexibility

When evaluating size options for your coaxial water cooled condenser, think about both physical dimensions and installation flexibility. A compact design may be beneficial if space is limited; however, ensure that it still meets your cooling requirements efficiently. The versatility of installation options allows for easier integration into existing systems or new projects alike.

Many modern designs offer modular components that enable seamless assembly with other equipment—this is particularly advantageous if you're looking at Arctic Active Cooling's Mini Water Chiller solutions which provide sophisticated designs integrated with high-efficient refrigeration parts. This adaptability means you won't have to compromise on performance even if you're working within tight spatial constraints or specific project requirements.

In conclusion, by focusing on efficiency metrics, durable materials, and flexible sizing options when choosing a coaxial water cooled condenser, you set yourself up for success in any cooling application—whether it's industrial processes or commercial refrigeration systems.

Popular Brands and Their Offerings

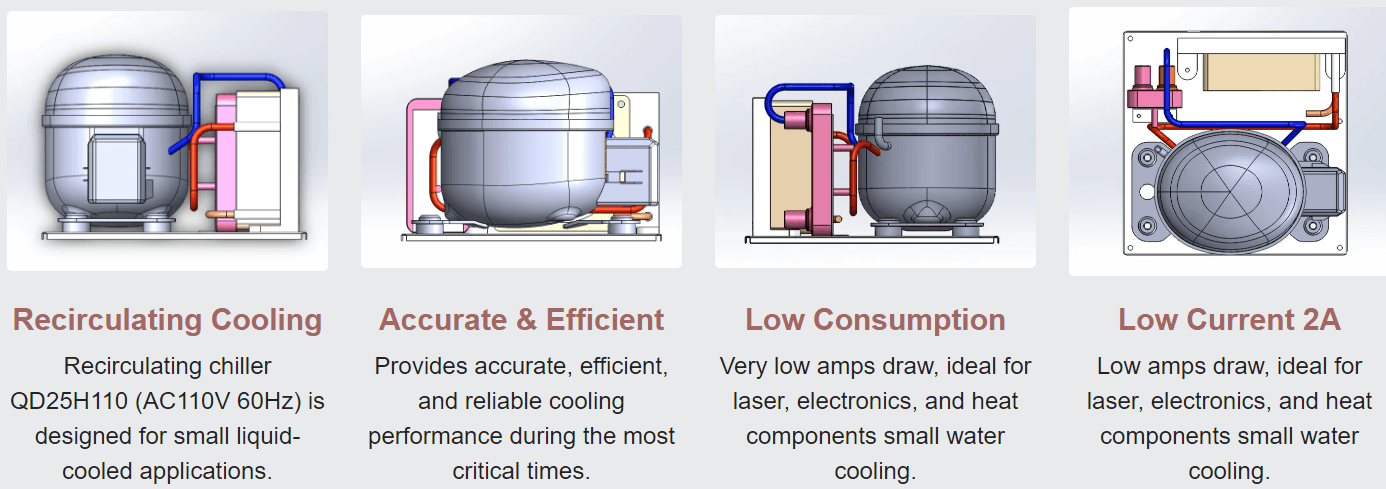

Arctic Active Cooling Solutions

Arctic Active Cooling Solutions stands out in the realm of coaxial water cooled condensers with their innovative Mini Water Chiller. This unit features a high-efficient refrigeration mini compressor utilizing R134a coolant, paired with the smallest condenser and a plate evaporator, all designed for seamless integration into existing systems. Their sophisticated engineering ensures that end users benefit from cutting-edge micro cooling solutions while simplifying installation processes.

What sets Arctic apart is their focus on customization; their Mini Water Chiller is perfect for customers who want to integrate cooling subsystem modules directly into their machinery. By allowing users to connect their control boards with the BLDC compressor driver board, Arctic enables tailored performance adjustments based on specific needs. This adaptability makes Arctic's offerings particularly appealing for OEM and ODM projects, ensuring that clients receive exactly what they require.

Other Leading Manufacturers

Beyond Arctic Active Cooling Solutions, several other leading manufacturers also offer impressive coaxial water cooled condensers worth considering. Brands like Alfa Laval and Tranter have made significant strides in providing efficient cooling solutions across various industries. Each of these companies brings unique features to their products that cater to different applications.

For instance, Alfa Laval specializes in plate heat exchangers which can be incorporated into coaxial designs for enhanced efficiency and space-saving benefits. Meanwhile, Tranter focuses on providing robust options that withstand harsh industrial environments without sacrificing performance or durability. When you shop coaxial water cooled condensers from these brands, you’re sure to find something that meets your specific requirements.

Unique Selling Points of Each Brand

Each brand has its own unique selling points when it comes to coaxial water cooled condensers, allowing customers to make informed decisions based on their needs and preferences. For Arctic Active Cooling Solutions, it’s all about compact design and user-friendly integration; they prioritize making advanced technology accessible without complicating installation.

On the other hand, Alfa Laval emphasizes versatility in design along with superior thermal efficiency through its innovative heat transfer technologies—perfect for those looking for high-performance solutions across varied applications. Tranter distinguishes itself by focusing on ruggedness and reliability; ideal for industries where equipment must endure demanding conditions while still delivering excellent cooling capabilities.

In summary, whether you're interested in a Coaxial Tube-in-Tube Water-Cooled Condenser or a Water Cooled Condenser Coaxial Coil design, exploring different brands will help you find the perfect fit for your project needs.

Installation and Maintenance Tips

Installing and maintaining a coaxial water cooled condenser is crucial for optimal performance and longevity. This section provides a comprehensive guide to ensure that your cooling system operates smoothly. Whether you’re looking to shop coaxial water cooled condensers or already have one installed, these tips will help you get the most out of your investment.

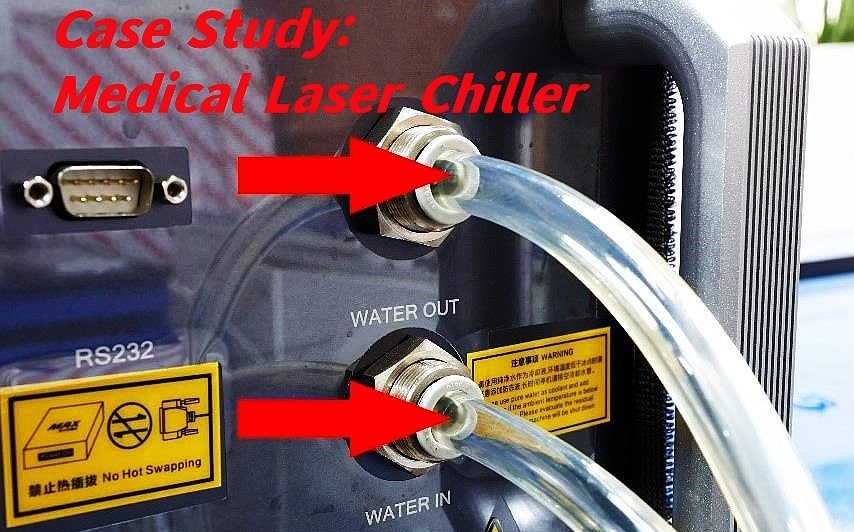

Step-by-Step Installation Guide

Installing a coaxial tube-in-tube water-cooled condenser requires careful planning and execution. Start by selecting an appropriate location that allows for adequate airflow and access to necessary utilities like water supply and electrical connections. Ensure that you have all required tools, including wrenches, screwdrivers, and safety gear before beginning the installation process.

Once you've prepared your workspace, begin by connecting the inlet and outlet pipes to the condenser unit according to the manufacturer’s specifications. Make sure to secure all fittings tightly to prevent leaks in your system. After connecting the pipes, install any additional components such as pumps or control boards as needed for your specific setup; Arctic Active Cooling's Mini Water Chiller can be integrated seamlessly into this process for those needing advanced micro cooling solutions.

Finally, double-check all connections before turning on your system. Fill the cooling loop with water and check for leaks while running a pressure test if applicable. Once satisfied with the integrity of your installation, power up the system and monitor its performance closely during initial operation.

Preventive Maintenance Practices

Regular maintenance is key to ensuring that your water cooled condenser operates at peak efficiency over time. Schedule routine inspections every few months where you check for signs of wear or damage on hoses, fittings, and other components associated with your coaxial water cooled condenser setup. Cleaning any debris from external surfaces can also help maintain airflow efficiency.

Pay special attention to checking fluid levels in both refrigerant and coolant systems; low levels can lead to inefficient operation or even damage over time if not addressed promptly. Additionally, inspect filters regularly—dirty filters can restrict flow rates causing increased energy consumption which defeats the purpose of having an efficient cooling system in place.

Consider investing in professional servicing once a year; skilled technicians can identify potential issues before they become major problems while also performing necessary repairs on components like compressors or evaporators within systems such as Arctic Active Cooling’s offerings.

Troubleshooting Common Issues

Even with regular maintenance practices in place, issues may still arise with coaxial tube-in-tube water-cooled condensers or other types of designs like the water cooled condenser coaxial coil variant mentioned earlier. If you notice unusual noises coming from your unit during operation—such as grinding or rattling—it could indicate loose parts or failing components that need immediate attention.

Another common issue involves inadequate cooling performance; if temperatures are not dropping as expected, check coolant levels first—insufficient fluid could be impacting heat exchange efficiency significantly! Also inspect for blockages within piping systems which might impede proper flow rates essential for effective heat transfer.

Lastly, if you're experiencing frequent cycling on/off behavior from compressors (especially relevant when integrating systems like Arctic Active Cooling's Mini Water Chiller), it may signal electrical issues requiring troubleshooting by qualified personnel familiar with these intricate setups designed around micro cooling solutions tailored specifically for OEM/ODM projects.

Conclusion

In conclusion, selecting the right coaxial water cooled condenser is essential for optimizing cooling efficiency and performance in various applications. With a range of options available, including the Coaxial Tube-in-Tube Water-Cooled Condenser and Water Cooled Condenser Coaxial Coil, it's crucial to assess your specific needs before making a decision. By understanding the unique features and benefits of each type, you can make an informed choice that enhances your cooling system.

Choosing the Best Coaxial Water Cooled Condenser

Different designs like the Coaxial Tube-in-Tube Water-Cooled Condenser offer varied performance characteristics that may suit your project better than others. Don't forget to shop coaxial water cooled condensers from reputable brands to ensure quality and reliability in your cooling systems.

Benefits of Using Quality Brands

Investing in quality brands for your water cooled condenser can lead to significant long-term savings and better performance outcomes. Leading manufacturers often provide advanced technology and superior materials that enhance durability while minimizing maintenance needs. For instance, Arctic Active Cooling's Mini Water Chiller stands out due to its compact design and high-efficiency refrigeration components, making it a smart choice for those looking for top-notch solutions.

Future Trends in Water Cooled Condensers

As technology advances, we can expect exciting developments in coaxial water cooled condensers that focus on energy efficiency and environmental sustainability. Innovations may include enhanced designs that further optimize heat transfer or integrate smart technology for improved control over cooling processes. Staying updated with these trends will help you choose cutting-edge solutions like the Water Cooled Condenser Coaxial Coil that meet future demands while ensuring reliable performance.