Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

Transport refrigeration units play a pivotal role in ensuring that perishable goods maintain their integrity during transit. These specialized systems are essential for various industries, including food and pharmaceuticals, where temperature control is non-negotiable. Understanding how transport refrigeration systems work can significantly impact the quality of products delivered to consumers.

Understanding Transport Refrigeration Units

So, what is a transport refrigeration system? At its core, it’s a technology designed to keep goods at specific temperatures while they’re on the move, whether it’s by truck, rail, or sea. These units not only preserve freshness but also ensure compliance with health regulations and standards that protect consumers.

Importance of Proper Cooling Techniques

Proper cooling techniques are critical for maintaining product quality and safety during transportation. Without adequate cooling, goods like fruits, vegetables, and medications can spoil or lose efficacy quickly. Hence, understanding how to transport refrigerated goods effectively is vital for businesses that depend on timely deliveries.

Key Components of Refrigeration Systems

The key components of refrigeration systems include compressors, condensers, evaporators, and thermal insulation materials—all working together to create an efficient cooling environment. Each part has a specific role in maintaining the desired temperature within transport refrigeration units. Knowing these components helps operators troubleshoot issues and ensures optimal performance throughout the transportation process.

What is a Transport Refrigeration System?

Transport refrigeration systems are specialized units designed to maintain low temperatures during the transportation of perishable goods. These systems are crucial for ensuring that items such as food, pharmaceuticals, and other temperature-sensitive materials arrive at their destination in optimal condition. Understanding what a transport refrigeration system entails is essential for anyone involved in logistics and supply chain management.

Overview of Refrigeration Technology

Refrigeration technology has evolved significantly over the years, becoming more efficient and reliable in preserving perishables during transport. At its core, refrigeration involves removing heat from an enclosed space to lower the temperature within that space, thus preventing spoilage. Transport refrigeration units utilize various methods—such as vapor compression or absorption cooling—to achieve this goal while being energy-efficient and environmentally friendly.

Types of Transport Refrigeration Systems

There are several types of transport refrigeration systems tailored to different needs and applications. The most common types include truck refrigeration units, trailer-mounted systems, and portable refrigerated containers (reefers). Each type has its unique features; for example, truck refrigeration units are often integrated into delivery vehicles for direct transport, while trailer-mounted systems offer flexibility for transporting larger loads over long distances.

Benefits for Food and Medical Industries

The benefits of using transport refrigeration systems extend far beyond simply keeping things cold; they play a critical role in maintaining food safety standards and ensuring medical supplies remain viable. In the food industry, these systems help preserve freshness, flavor, and nutritional value while minimizing waste due to spoilage. Similarly, in the medical field, proper temperature control is vital for transporting vaccines and other sensitive materials safely—ensuring they remain effective upon arrival.

How to Transport Refrigerated Goods?

Transporting refrigerated goods is a critical process that ensures the integrity and quality of temperature-sensitive products. It requires careful planning and execution to maintain optimal conditions throughout the journey. By understanding best practices, utilizing effective temperature monitoring techniques, and emphasizing route planning efficiency, businesses can enhance their transport refrigeration units' performance.

Best Practices for Loading and Unloading

Loading and unloading are pivotal moments in the transport of refrigerated goods that can significantly impact product quality. To maximize efficiency, it's essential to load items in a manner that allows for proper air circulation within the transport refrigeration unit. Additionally, always ensure that the refrigeration unit is pre-cooled before loading; this helps maintain consistent temperatures during transit.

When unloading, speed is key—reduce exposure time to ambient temperatures by having your unloading area prepared in advance. This means having staff ready and equipment on standby to facilitate quick transfers from truck refrigeration units to storage areas. Remember, every second counts when it comes to maintaining the cold chain; improper loading or unloading can lead to spoilage or product loss.

Temperature Monitoring Techniques

Regularly reviewing temperature data allows businesses to identify patterns or issues that may arise during transit, facilitating proactive adjustments in future shipments. Moreover, integrating these techniques with your truck refrigeration unit's capabilities enhances overall operational efficiency and reliability. Ultimately, effective temperature monitoring safeguards perishable goods against potential losses due to inadequate cooling.

Importance of Route Planning for Efficiency

Efficient route planning plays a crucial role in optimizing how you transport refrigerated goods while minimizing risks associated with delays or unexpected stops. By analyzing traffic patterns and weather conditions ahead of time, logistics managers can choose routes that reduce travel time without compromising safety standards for their transport refrigeration units.

Moreover, incorporating planned stops at appropriate intervals allows for necessary checks on both vehicle performance and cargo condition—ensuring everything remains within specified limits throughout transit. With well-planned routes, companies not only save time but also conserve fuel resources while ensuring their truck refrigeration units operate at peak efficiency.

In summary, adhering to best practices for loading/unloading processes combined with robust temperature monitoring techniques and efficient route planning forms a trifecta of success in transporting refrigerated goods effectively.

What are the Units for Refrigeration Capacity?

When discussing transport refrigeration units, understanding the units of refrigeration capacity is crucial for effective cooling. The most common unit used in this context is the British Thermal Unit (BTU), which measures the amount of heat needed to raise the temperature of one pound of water by one degree Fahrenheit. Knowing how to interpret these metrics helps ensure that your refrigeration systems operate efficiently and effectively.

Understanding BTUs and Refrigeration Metrics

BTUs serve as a fundamental metric for gauging the performance of transport refrigeration systems. For instance, a higher BTU rating indicates a greater ability to remove heat from a space, making it vital when selecting what is a truck refrigeration unit or any other type of refrigeration unit. Additionally, other metrics such as tonnage and wattage also play important roles in determining how well these systems can maintain desired temperatures during transport.

How to Calculate Cooling Requirements

Calculating cooling requirements involves several factors that contribute to the efficiency of your transport refrigerated goods system. Key elements include ambient temperature, insulation quality, and product load; all must be factored in to determine how many BTUs are necessary for optimal performance. By accurately assessing these variables, you can ensure that your chosen refrigeration unit meets your specific needs without overloading or underutilizing its capabilities.

Importance of Sizing Transport Refrigeration Units

Proper sizing of transport refrigeration units cannot be overstated; it directly impacts energy efficiency and operational costs. An oversized unit may cycle on and off frequently, leading to increased wear and tear while consuming more energy than necessary. Conversely, an undersized system will struggle to maintain temperatures, risking spoilage during transit—an outcome no one wants when learning how to transport refrigerated goods effectively.

What is a Truck Refrigeration Unit?

Truck refrigeration units are specialized systems designed to maintain low temperatures during the transportation of perishable goods. These units are essential for industries that rely on the cold chain, such as food and pharmaceuticals, ensuring that products remain safe and fresh from point A to point B. Understanding what constitutes a truck refrigeration unit is crucial for anyone involved in logistics or supply chain management.

Features of Truck Refrigeration Systems

Truck refrigeration systems come equipped with several key features that enhance their efficiency and effectiveness. Most notably, they include advanced temperature control mechanisms, allowing precise adjustments to maintain optimal conditions for various types of cargo. Additionally, these transport refrigeration units often have insulation designed to minimize thermal loss, ensuring that the interior remains consistently cool even in challenging external environments.

Another significant feature is their ability to operate on different power sources—either through the truck's engine or via an independent generator system. This versatility allows for continuous cooling during both transit and loading/unloading operations. Furthermore, many modern truck refrigeration units boast real-time temperature monitoring capabilities, providing peace of mind by alerting operators if temperatures deviate from set ranges.

Comparison of Truck Units and Other Refrigeration Types

When comparing truck refrigeration units to other types of refrigeration systems, several distinctions emerge that highlight their unique advantages. For instance, while traditional static refrigerated warehouses provide consistent cooling for stored goods, transport refrigeration units offer mobility—allowing perishable items to be moved across long distances without compromising quality. This flexibility is vital in industries where timely delivery is critical.

Moreover, unlike smaller portable refrigerators used for personal use or limited applications, truck refrigeration systems are engineered for larger loads and more demanding environments. They can handle a greater volume of goods while maintaining stringent temperature controls necessary for sensitive products like pharmaceuticals or fresh produce. Thus, when considering how to transport refrigerated goods effectively, opting for a dedicated truck unit often proves advantageous over other methods.

Maintenance Tips for Truck Refrigeration Units

To ensure optimal performance and longevity of truck refrigeration units, regular maintenance is paramount. One key tip involves routinely checking refrigerant levels; insufficient refrigerant can lead to inadequate cooling performance and potential spoilage of transported items. Additionally, inspecting seals and insulation regularly will help prevent cold air leaks that could compromise the internal environment.

Another important aspect is cleaning the condenser coils periodically; dirty coils can hinder heat exchange efficiency and strain the system's energy consumption—leading to higher operational costs over time. Operators should also familiarize themselves with any specific maintenance requirements outlined by manufacturers regarding filter replacements or software updates related to digital monitoring systems.

Finally, keeping detailed logs of maintenance activities can aid in identifying patterns over time; this proactive approach helps catch potential issues before they escalate into costly repairs or service interruptions—keeping your transport refrigeration units running smoothly when it matters most.

Exploring Arctic Active Cooling Technology

Transport refrigeration units have evolved significantly, and one of the standout innovations is Arctic Active Cooling technology. This advanced cooling solution offers unmatched efficiency and reliability, addressing the critical needs of various industries that rely on maintaining optimal temperatures for their goods. Understanding how these units work and their applications can provide valuable insights into modern refrigeration systems.

Overview of Arctic Active Cooling Units

Arctic Active Cooling Units are designed with cutting-edge technology to enhance the performance of transport refrigeration systems. These units feature a compact design that maximizes space while providing robust cooling capabilities essential for transporting perishable goods. By integrating innovative engineering, these refrigeration units ensure consistent temperature control, making them an ideal choice for businesses in need of reliable transport solutions.

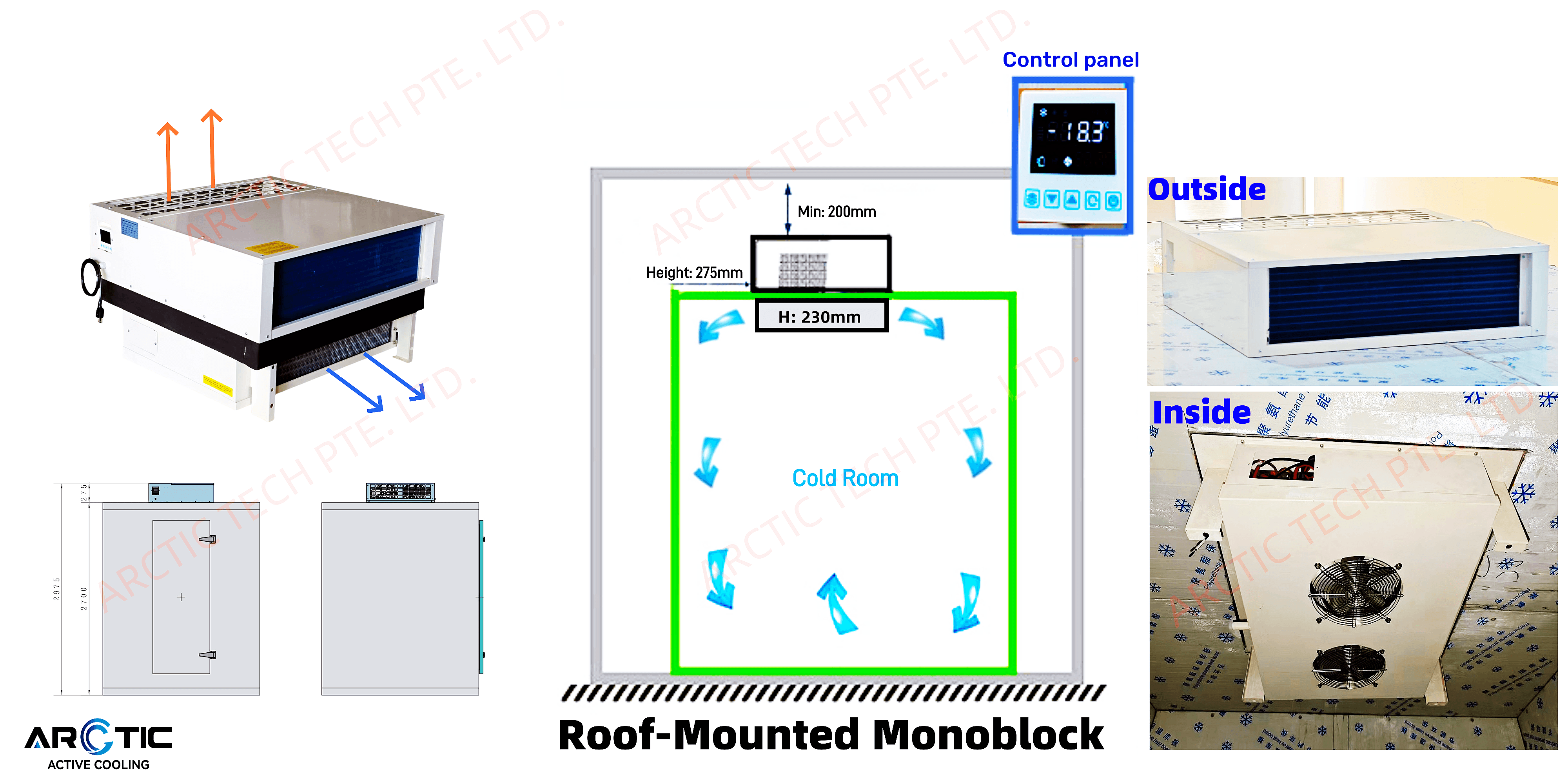

Benefits of Top-Mounted Monoblock Refrigeration Units

The Top-Mounted Monoblock Refrigeration Unit by Arctic Active Cooling stands out due to its efficiency and ease of installation. This all-in-one unit is perfect for commercial refrigerators, freezers, and small to mid-sized cold rooms, offering a seamless solution for any business looking to optimize its cooling processes. With features designed to maintain optimal humidity and temperature levels, these transport refrigeration units are particularly beneficial in preserving products like fresh flowers in florists or wholesale markets.

Moreover, the monoblock design minimizes maintenance requirements while maximizing energy savings—an essential factor when considering how to transport refrigerated goods effectively. The convenience offered by such an integrated system means businesses can focus more on operations rather than worrying about equipment failure or inefficiencies.

Applications in Cold Rooms and Beyond

The applications for Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit extend far beyond traditional cold storage rooms; they are versatile enough to serve various sectors including food service, pharmaceuticals, and even floral arrangements. In cold rooms specifically designed for perishable items, these units maintain precise temperature control crucial for extending product shelf life.

Additionally, their ability to handle diverse load conditions makes them suitable not just for food but also medical supplies that require stringent temperature regulations—a key consideration when exploring what is a transport refrigeration system? As industries continue adapting to changing demands, incorporating such advanced technologies ensures efficient operations while meeting regulatory standards.

Conclusion

In the world of logistics and supply chain management, understanding transport refrigeration units is paramount for ensuring the safe delivery of temperature-sensitive goods. A transport refrigeration system is not just a luxury; it’s a necessity for industries like food and pharmaceuticals where maintaining specific temperatures is crucial. By mastering the ins and outs of these systems, businesses can significantly improve their operational efficiency and product quality.

Key Takeaways on Refrigeration Systems

Transport refrigeration units are essential for preserving perishable items during transit, ensuring that products arrive at their destination in peak condition. Understanding what a transport refrigeration system entails, including its various types and components, can help businesses make informed decisions about their logistics needs. Moreover, knowing how to transport refrigerated goods effectively—by adhering to best practices—can lead to reduced spoilage rates and increased customer satisfaction.

Best Practices for Efficient Transport

When it comes to transporting refrigerated goods, best practices play a vital role in maintaining the integrity of the products being shipped. Proper loading techniques can prevent damage and ensure even temperature distribution within the truck refrigeration unit, while temperature monitoring techniques are crucial for real-time tracking of conditions throughout transit. Additionally, effective route planning not only saves time but also minimizes fuel consumption, making your operations more sustainable.

Future Innovations in Transport Refrigeration Units

The future of transport refrigeration units looks bright with advancements in technology promising even greater efficiency and reliability. Innovations such as Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit are setting new benchmarks by providing all-in-one solutions tailored to modern cooling applications in cold rooms and beyond. As these technologies continue to develop, we can expect enhanced performance capabilities that will further support industries reliant on precise temperature control.