Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the world of HVAC systems, understanding the condenser water loop is essential for ensuring optimal performance. What is the condenser water loop, you ask? Simply put, it’s a system that circulates chilled water through various components to absorb heat and maintain comfortable indoor temperatures. The purpose of a water loop extends beyond just cooling; it plays a pivotal role in energy efficiency and system reliability.

However, as with any mechanical system, common challenges arise in condenser water systems that can hinder performance. Issues such as uneven cooling distribution and cold spots can plague even the best-designed setups. What is water looping if not a well-oiled machine? Addressing these challenges requires both knowledge and proactive measures to ensure smooth operation.

In this context, simple solutions matter immensely. Often, minor adjustments or routine maintenance can lead to significant improvements in efficiency and comfort levels. By focusing on HVAC system optimization through straightforward strategies, facility managers can enhance their systems without breaking the bank or overcomplicating processes.

Identifying Cold Spots in Your System

In any HVAC system, particularly those utilizing a condenser water loop, identifying cold spots is crucial for maintaining optimal efficiency. Cold spots can indicate issues such as inadequate flow or system imbalances, which can lead to increased energy costs and reduced performance. By employing various techniques and tools, you can effectively pinpoint these problematic areas and ensure your water loop operates at its best.

Thermal Imaging Techniques

Thermal imaging is a powerful tool that provides a quick visual assessment of temperature variations within your condenser water loop. By using an infrared camera, you can easily identify cold spots that may not be detectable through traditional inspection methods. This non-invasive technique allows for real-time monitoring and helps in diagnosing issues like insulation failures or leaks within the system.

When utilizing thermal imaging, it's essential to understand what you're looking for: significant temperature differences between components in the condenser water loop could signify inefficiencies or failures in the system. Regular thermal scans can help track performance over time and highlight trends that may require attention. Ultimately, this method contributes to HVAC system optimization by ensuring all parts are functioning harmoniously.

Manual Inspection Best Practices

Manual inspections remain a tried-and-true method for identifying cold spots in your condenser water loop. When performing these inspections, start by checking all accessible pipes and connections for signs of condensation or frost buildup—both are indicators of uneven cooling or flow issues. Additionally, ensure that air vents are unobstructed and functioning properly; poor airflow can exacerbate cold spot problems.

It's also wise to pay attention to the layout of your system; understanding how water looping works will help you identify potential bottlenecks where flow might be restricted. Furthermore, engaging with maintenance staff during manual inspections fosters a collaborative approach to troubleshooting issues as they arise. Consistent manual checks complement other methods like thermal imaging and contribute significantly to overall HVAC system optimization.

Utilizing Flow Meters

Flow meters play an indispensable role in monitoring the efficiency of your condenser water loop by providing real-time data on flow rates throughout the system. By installing these devices at strategic points within your setup, you gain insights into whether you're achieving ideal flow rates—crucial for effective cooling performance and energy savings alike. If discrepancies arise between expected and actual readings, it may indicate underlying problems such as blockages or pump malfunctions.

Understanding how a chilled water loop works involves recognizing that consistent flow is necessary for optimal heat exchange; thus, utilizing flow meters allows you to make informed decisions about adjustments needed within the system. Regularly reviewing data from these meters enables proactive maintenance strategies rather than reactive fixes after issues have escalated into costly repairs or downtime. In summary, integrating flow meters into your routine checks enhances overall HVAC system optimization while ensuring that every component operates efficiently.

Optimizing Flow Rates for Efficiency

Optimizing flow rates in a condenser water loop is pivotal for achieving peak performance and energy efficiency. Understanding the dynamics of your system can lead to significant savings and improved operation. By focusing on the right calculations, equipment, and real-world applications, you can elevate your HVAC system optimization efforts.

Calculating Ideal Flow Rates

To answer the question, What is the purpose of a water loop? we must first understand how to calculate ideal flow rates within a condenser water loop. The flow rate should be determined based on the heat load requirements of your system, typically measured in gallons per minute (GPM). This calculation ensures that enough chilled water circulates through the loop to maintain optimal temperatures without overworking pumps or cooling units.

Accurate calculations also consider factors like temperature differentials and specific heat capacities of the fluids involved. By understanding these metrics, you can make informed decisions that enhance efficiency and reduce wear on components within your HVAC system. Ultimately, calculating ideal flow rates not only answers fundamental questions about water looping but also sets the stage for effective system management.

Benefits of Variable Speed Pumps

Variable speed pumps are game-changers when it comes to optimizing flow rates in a condenser water loop. These pumps adjust their speed according to real-time demand, which means they only use as much energy as necessary at any given time. As a result, this leads to lower energy costs while maintaining consistent performance across various load conditions.

Moreover, variable speed pumps help prevent issues such as hydraulic shock or pressure surges that can occur with traditional fixed-speed systems. This adaptability enhances overall reliability and extends equipment lifespan—an essential consideration for anyone looking into what is water looping at its most efficient level. With these benefits in mind, it's clear that investing in variable speed technology is an intelligent move for any HVAC system optimization strategy.

Real-Life Success Stories

Many organizations have experienced significant improvements by implementing optimized flow rates through their condenser water loops using variable speed pumps and precise calculations. For instance, one commercial building reported a 30% reduction in energy consumption after recalibrating its system based on calculated ideal flow rates and installing variable speed pumps tailored for their needs. This transformation not only cut costs but also enhanced tenant comfort levels—a win-win situation!

Another success story involves an industrial facility that faced challenges with fluctuating temperatures across its production floor due to inadequate cooling distribution from its existing setup. By re-evaluating their approach to what is the condenser water loop configuration they had been using and integrating Arctic Active Cooling's Mini Water Chiller into their existing infrastructure, they achieved remarkable temperature stability while optimizing energy use effectively.

These real-life examples illustrate how understanding and optimizing flow rates can lead directly to tangible benefits—making it clear why such strategies should be prioritized in any discussion about HVAC system optimization.

Benefits of Regular Maintenance

Regular maintenance is crucial for the longevity and efficiency of your condenser water loop. Neglecting routine checks can lead to decreased performance, increased energy costs, and even system failures. So, what is the purpose of a water loop? It's designed to efficiently circulate chilled water throughout your HVAC system, ensuring optimal cooling performance.

Setting a Maintenance Schedule

Creating a maintenance schedule for your condenser water loop is essential for effective HVAC system optimization. This schedule should include regular inspections, cleaning of components, and checks on fluid levels and flow rates. By adhering to a well-planned timetable, you can prevent minor issues from escalating into major problems that can disrupt your cooling operations.

Tools You’ll Need

To maintain an efficient condenser water loop, you'll need some specialized tools in your toolkit. Essential items include thermal imaging cameras for detecting temperature variations, pressure gauges for monitoring system performance, and flow meters to assess circulation rates effectively. Having the right equipment not only simplifies maintenance tasks but also enhances your ability to identify what is water looping in your system.

Signs a System Needs Attention

Recognizing signs that indicate your condenser water loop needs attention can save you time and money in the long run. Look out for erratic temperature fluctuations or noticeable cold spots which could signal inefficiencies within the loop—this might mean it’s time for some troubleshooting! Additionally, unusual noises or vibrations during operation often hint at underlying issues that require prompt intervention.

Innovative Solutions from Arctic Active Cooling

In the world of HVAC system optimization, the introduction of innovative solutions can significantly enhance efficiency and performance. One such solution is Arctic Active Cooling's Mini Water Chiller, designed specifically to meet the needs of modern condenser water loops. By integrating advanced technology into a compact unit, it addresses common challenges faced by users looking for effective cooling solutions.

Features of the Mini Water Chiller

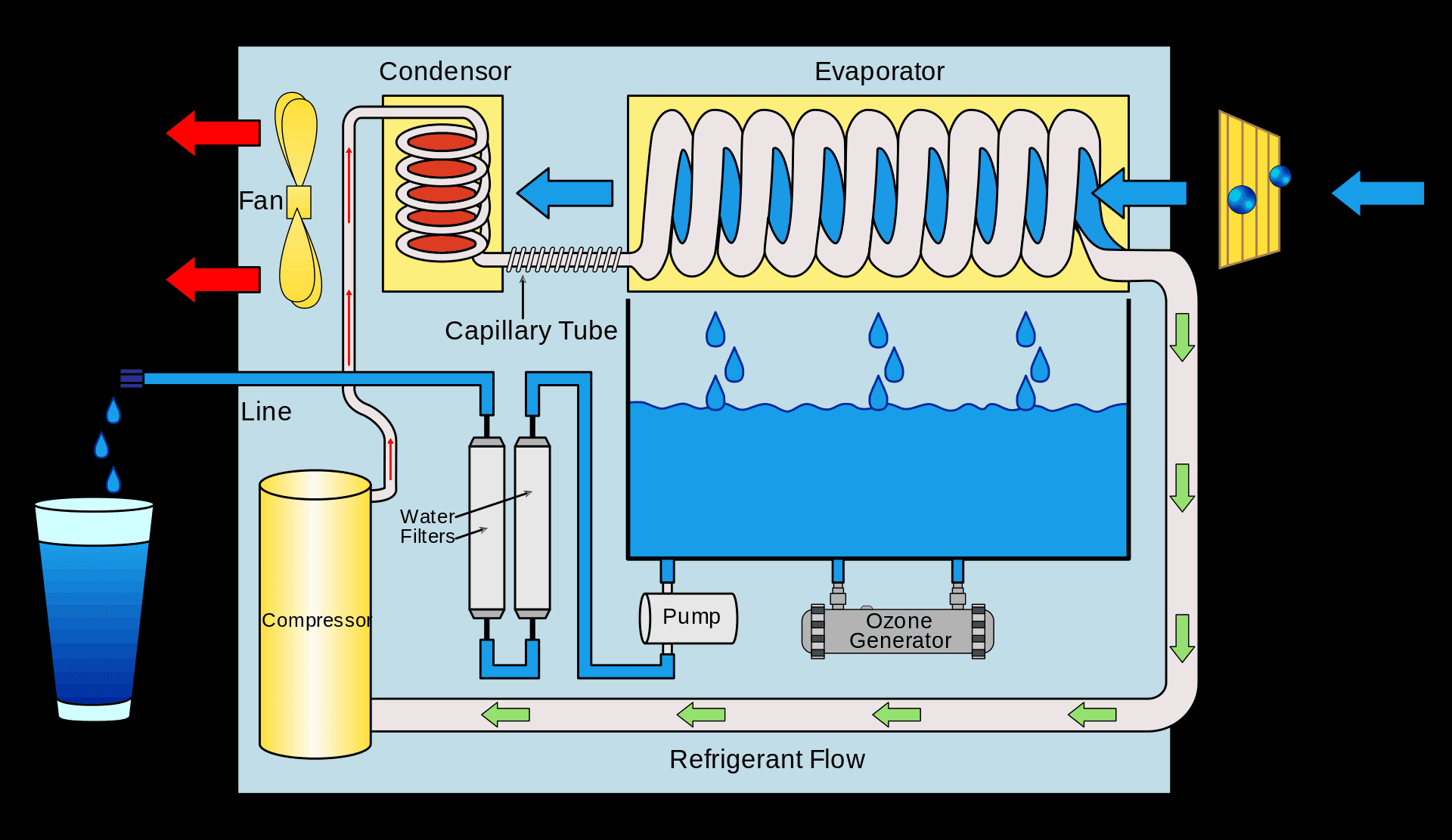

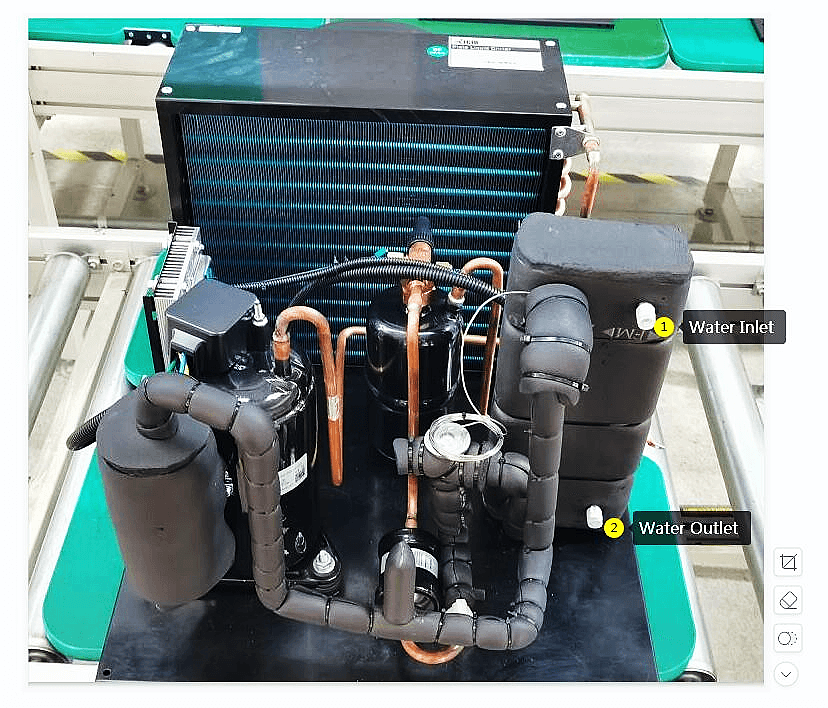

The Mini Water Chiller boasts a high-efficient refrigeration mini compressor utilizing R134a coolant, making it an ideal choice for those asking, What is the purpose of a water loop? This compact chiller integrates essential components such as the smallest condenser and plate evaporator within one sophisticated design. Its streamlined assembly not only simplifies installation but also ensures that users benefit from cutting-edge micro cooling solutions tailored for their specific needs.

Equipped with a filter drier and drive board, this unit is perfect for customers who are adept at managing system control. They can easily connect their control board to our BLDC compressor driver board to optimize performance based on their unique requirements. The Mini Water Chiller exemplifies how innovation in water looping can lead to improved efficiency in condenser water loops.

Integration with Existing Systems

When considering How does a chilled water loop work? it's essential to understand that seamless integration with existing systems is key to maximizing performance. The Mini Water Chiller is designed for easy assembly with various machines or equipment, allowing businesses to upgrade their cooling capabilities without overhauling entire systems. This flexibility makes it an attractive option for those looking to enhance their current HVAC setup while maintaining operational continuity.

By utilizing Arctic Active Cooling’s chiller alongside existing components in a condenser water loop, users can achieve optimal flow rates and thermal regulation without significant disruptions. Its innovative design means that even older systems can be revitalized with state-of-the-art cooling technologies without excessive costs or complex retrofitting processes. This adaptability speaks volumes about how modern solutions can breathe new life into traditional setups.

Case Studies and User Feedback

Real-world applications often provide valuable insights into any product's effectiveness—especially when discussing HVAC system optimization through innovative tools like the Mini Water Chiller. Numerous case studies have highlighted successful integrations where businesses reported significant improvements in efficiency and reduced energy consumption after implementing this chiller into their existing setups. Users consistently praise its ease of installation and remarkable performance enhancements within their condenser water loops.

Feedback from clients indicates that they appreciate how well this mini chiller fits into various configurations while addressing specific cooling needs effectively—demonstrating its versatility across different industries and applications alike. As more companies seek out effective answers to questions like What is water looping? they find that Arctic Active Cooling’s solutions stand out as reliable options worth considering for long-term investment in energy-efficient technologies.

Smart Controls for Better Performance

In the realm of HVAC system optimization, smart controls are revolutionizing how we manage condenser water loops. By utilizing advanced technology, these controls enhance efficiency and reliability while reducing energy consumption. Understanding the components involved, such as compressor control boards, is essential for maximizing the benefits of a well-designed water loop.

Understanding Compressor Control Boards

Compressor control boards are integral to the operation of any condenser water loop. They regulate compressor speed and performance based on real-time data from the system, ensuring optimal cooling without unnecessary energy expenditure. This intelligent management is crucial because it directly influences how effectively a chilled water loop works in tandem with other HVAC components.

The purpose of a water loop is not just to provide cooling but to do so efficiently and sustainably. With compressor control boards managing load variations, systems can adapt dynamically to changing conditions, making them more resilient against fluctuations in demand. Consequently, this leads to improved overall performance and longevity of your HVAC system.

How to Select the Right Components

When selecting components for your condenser water loop, it's vital to consider compatibility with existing systems and operational needs. Opt for high-quality parts that offer flexibility; this ensures seamless integration whether you’re upgrading an old setup or installing a new one from scratch. Remember that choosing the right components can significantly impact both efficiency and maintenance costs over time.

For instance, Arctic Active Cooling’s Mini Water Chiller provides an excellent example of how modern technology can enhance your system’s capabilities. This unit features a sophisticated design that integrates all necessary refrigeration parts into one compact solution—making installation easier while ensuring top-notch performance in any application involving water looping.

Moreover, ensure that your selected components allow for easy communication with your control board—a critical factor when aiming for effective HVAC system optimization.

Real-World Applications of Smart Controls

Real-world applications of smart controls in condenser water loops showcase their transformative potential across various sectors—from commercial buildings to industrial facilities. For example, many businesses have reported significant reductions in energy costs after implementing smart controls alongside their chilled water loops due to optimized flow rates and reduced wear on equipment.

One notable case involves a manufacturing plant that integrated Arctic Active Cooling's Mini Water Chiller into its existing setup; they experienced not only enhanced cooling performance but also improved operational flexibility thanks to precise control over compressor speed via their custom board connection. This highlights how strategic use of technology can lead to substantial gains in efficiency while maintaining comfort levels across large spaces.

As we continue exploring innovative solutions within our HVAC systems, it becomes increasingly clear that investing in smart controls is not merely beneficial—it’s essential for staying competitive in today’s market.

Conclusion

In wrapping up our exploration of condenser water loops, it’s essential to recognize their pivotal role in HVAC system optimization. Understanding what a condenser water loop is and its purpose lays the groundwork for effective cooling solutions. With the right knowledge and tools, managing these systems can lead to significant energy savings and improved performance.

Key Takeaways on Cold Condenser Water Loops

What is the condenser water loop? It’s a vital part of many cooling systems, designed to transfer heat away from chillers or other cooling equipment. By grasping how does a chilled water loop work, operators can better manage flow rates and maintain efficiency, ensuring that they’re not just circulating water but optimizing their entire HVAC system.

Moreover, knowing what is water looping and its importance helps in identifying areas for improvement within your setup. Regular monitoring can pinpoint inefficiencies like cold spots or improper flow rates that hinder performance. Remember, effective management of your condenser water loop translates directly into lower operating costs and enhanced comfort levels in any facility.

The Importance of Regular System Reviews

Regular reviews of your condenser water loop are not just beneficial; they’re crucial for optimal function over time. By routinely assessing your system’s performance, you can catch issues before they escalate into costly repairs or replacements. What is the purpose of a water loop if not to provide reliable cooling? Keeping an eye on its health ensures it fulfills this role effectively.

A well-maintained system also aids in sustaining energy efficiency standards and prolonging equipment life—two key factors in today’s environmentally conscious world. Furthermore, regular maintenance checks can help you identify trends that may indicate future problems with your chilled water loop operations. Ultimately, investing time into thorough system reviews pays dividends through reduced downtime and enhanced operational reliability.

Future Trends in Cooling Technology

Looking ahead at future trends in cooling technology reveals exciting advancements that could redefine how we interact with our condenser water loops. Innovations such as smart controls are emerging to optimize HVAC system performance further by automating adjustments based on real-time data analysis. This means less manual intervention and more efficient operation—what a win-win!

Additionally, Arctic Active Cooling's Mini Water Chiller exemplifies how modern engineering is pushing boundaries with compact designs that integrate seamlessly into existing setups while offering high-efficiency refrigeration solutions for various applications. As industries continue to evolve towards greater sustainability goals, understanding what is the condenser water loop will become even more critical for maintaining competitive advantages.

Embracing these advancements not only enhances current systems but prepares us for future challenges in climate control technologies overall—ensuring we stay cool when things heat up!