Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the realm of temperature control and preservation, monoblock refrigeration units have emerged as a powerful solution for various cold storage needs. But what is a monoblock refrigeration system? These self-contained units combine all essential components into a single housing, making them an efficient choice for businesses looking to maintain optimal temperatures. From florists to grocery stores, understanding how these systems work can significantly impact your operational efficiency.

Understanding Monoblock Refrigeration Systems

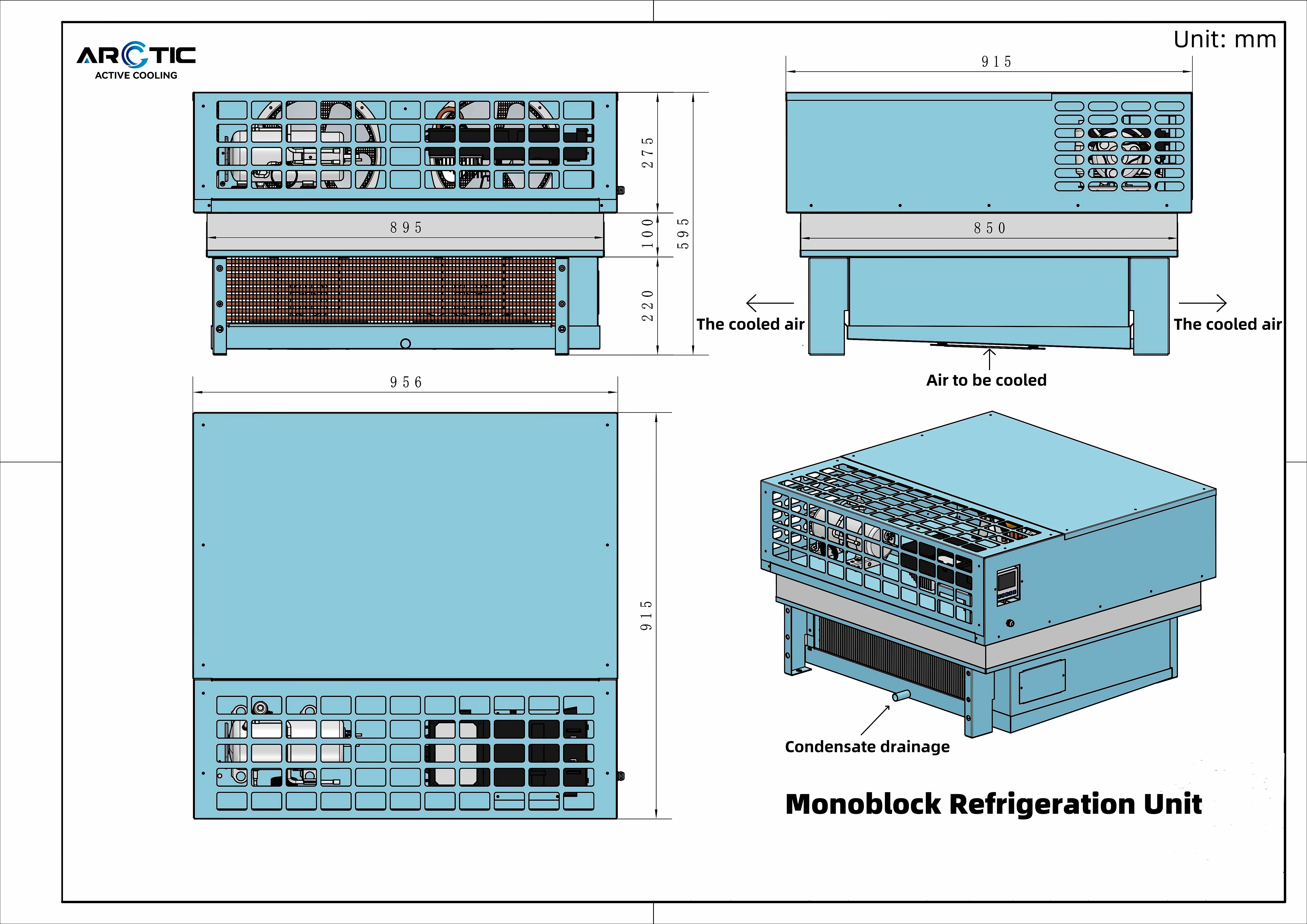

Monoblock refrigeration systems are designed with simplicity and effectiveness in mind. They typically consist of a compressor, condenser, evaporator, and expansion valve—all neatly packed into one unit. This compact design not only saves space but also streamlines installation and maintenance processes, making it easier for businesses to manage their cold storage solutions.

Advantages of Monoblock Refrigeration Units

One of the standout features of monoblock refrigeration units is their energy efficiency. Compared to traditional systems, they often consume less power while providing consistent cooling performance. Additionally, these units are known for their reliability and low maintenance requirements—qualities that can lead to significant cost savings over time.

Choosing the Right Monoblock Cooler

When it comes to selecting the ideal monoblock cooler for your business needs, several factors come into play. Considerations such as size, cooling capacity, and specific application requirements are crucial in ensuring you make the right choice. It's also important to understand what is a monoblock compressor and how it fits into your chosen system—this knowledge will help you optimize performance while minimizing energy consumption.

What is a Monoblock Refrigeration System?

A monoblock refrigeration system is a compact, self-contained unit designed to provide efficient cooling for various applications, particularly in cold storage facilities. These systems are engineered to combine all necessary components, such as compressors, condensers, and evaporators, into one integrated package. This design not only simplifies installation but also enhances performance and reliability.

Key Components of Monoblock Systems

The key components of a monoblock refrigeration unit include the compressor, condenser, evaporator, and expansion valve. The compressor is responsible for circulating refrigerant throughout the system; it compresses low-pressure gas into high-pressure gas. The condenser cools this gas back into a liquid state while the evaporator absorbs heat from the environment to provide cooling; the expansion valve regulates refrigerant flow.

In essence, these components work together seamlessly within a single housing to create an efficient cooling cycle. This integration makes maintenance more straightforward since all critical parts are located in one place. Moreover, it allows for better energy efficiency compared to traditional setups that require separate units for each component.

How Monoblock Refrigeration Works

So how does a monoblock refrigeration system work? It begins with the compressor drawing in low-pressure refrigerant vapor from the evaporator and compressing it into high-pressure vapor. This vapor then travels through the condenser where it releases heat and condenses into a liquid before passing through an expansion valve that reduces its pressure as it enters the evaporator.

In the evaporator, this low-pressure liquid absorbs heat from its surroundings—essentially cooling down whatever is inside your cooler or storage space—before returning to the compressor as vapor to repeat this cycle again. This continuous loop ensures that your perishable goods remain at optimal temperatures without excessive energy consumption or complex machinery setups. Understanding what is a monoblock cooler can help businesses streamline their refrigeration needs effectively.

Benefits for Cold Storage Facilities

Monoblock refrigeration units offer numerous benefits specifically tailored for cold storage facilities. First off, their compact design allows them to fit into tight spaces while still delivering powerful cooling capabilities—perfect for those cramped grocery store backrooms or flower market coolers!

Additionally, these units typically require less maintenance than traditional systems due to their integrated nature; fewer parts mean fewer potential points of failure—and who doesn’t love reliability when storing valuable inventory? Finally, energy efficiency is another significant advantage: monoblock systems often consume less electricity than separate components would collectively use.

In summary, understanding what is a monoblock refrigeration system reveals just how beneficial these units can be in modern commercial applications—from florists needing fresh blooms daily to restaurants requiring precise temperature control for ingredients.

What is a Monoblock Compressor?

When discussing refrigeration technology, the monoblock compressor often takes center stage, particularly in the context of a monoblock refrigeration unit. This type of compressor is designed as a single, integrated unit that combines multiple functions into one compact system. Essentially, it streamlines the refrigeration process by housing all necessary components—compressor, condenser, and evaporator—within one casing.

Functionality of Monoblock Compressors

Monoblock compressors operate by compressing refrigerant gas and circulating it through the cooling system. In a monoblock refrigeration unit, these compressors play a pivotal role in maintaining optimal temperatures for various applications. Their design allows for efficient heat exchange and minimizes energy loss during operation.

In practical terms, when you ask What is a monoblock compressor? you're looking at an innovative solution that enhances reliability while simplifying installation and maintenance processes. The compact nature of these units makes them ideal for cold storage facilities where space can be limited. They also provide consistent cooling performance across different environments.

Comparison with Traditional Compressors

When comparing monoblock compressors to traditional compressors, several distinctions stand out. Traditional systems often require separate components that can complicate installation and take up more space; this can lead to higher costs and more potential points of failure. In contrast, the integration found in a monoblock refrigeration unit offers streamlined functionality that reduces both complexity and maintenance needs.

Moreover, traditional compressors may struggle with energy efficiency compared to their monoblock counterparts. With fewer moving parts and an optimized design for heat transfer, what you get with a monoblock cooler is enhanced performance without sacrificing energy consumption. This efficiency not only lowers operational costs but also contributes to sustainability efforts within your business.

Efficiency and Energy Savings

One of the standout features of monoblock compressors is their ability to deliver impressive energy savings over time. By utilizing advanced technology within these units, they typically operate at lower power levels while achieving effective cooling results—an essential consideration for any cold storage facility or commercial application asking What are the four types of refrigeration systems?

The reduced energy consumption translates into significant cost savings on utility bills while also minimizing environmental impact—a win-win situation for businesses looking to enhance their operational efficiency without compromising on performance quality. As companies increasingly prioritize sustainability alongside profitability, investing in a reliable monoblock refrigeration unit becomes an attractive option worth considering.

Exploring Different Types of Refrigeration Systems

Overview of the Four Types of Refrigeration

The four main types of refrigeration systems include vapor-compression, absorption, thermoelectric, and magnetic refrigeration. Each system operates on distinct principles; for example, vapor-compression relies on a refrigerant to absorb and release heat efficiently. The monoblock refrigeration system falls under the vapor-compression category but offers a compact design that simplifies installation and maintenance.

Advantages of Monoblock Refrigeration Units

Monoblock refrigeration units are celebrated for their energy efficiency and ease of use. Unlike traditional systems that require complex setups with multiple components, a monoblock cooler integrates all necessary parts into a single unit, reducing installation time and costs significantly. This streamlined approach not only saves space but also enhances reliability—ideal for businesses looking to optimize their cold storage solutions.

Ideal Applications for Each System

Understanding what is a monoblock refrigeration system helps in identifying its ideal applications across various industries. Monoblock systems excel in environments like grocery stores or restaurants where space is limited but cooling needs are high. Conversely, larger industrial operations may benefit from more extensive setups like centralized cooling or absorption systems tailored for vast spaces.

Features of Arctic Active Cooling Units

Arctic Active Cooling Units are revolutionizing the way we think about temperature control in commercial settings. These units, a type of monoblock refrigeration unit, are designed with innovative technology that enhances their performance and efficiency. Understanding what makes these systems stand out can help businesses make informed decisions about their cold storage solutions.

Advanced Cooling Technology

At the heart of every Arctic Active Cooling Unit lies advanced cooling technology that ensures optimal temperature regulation. This cutting-edge system is often encapsulated in a compact design known as a monoblock refrigeration system, which integrates all components into one cohesive unit. By minimizing the need for external parts, these coolers reduce installation time and potential points of failure while maximizing reliability.

The cooling process begins with a monoblock compressor that efficiently compresses refrigerant gas, allowing it to circulate through various components. This seamless integration not only streamlines operations but also enhances performance during peak demand periods. With features like variable speed fans and intelligent control systems, Arctic units adapt to changing conditions for superior temperature management.

Energy Efficiency and Sustainability

Energy efficiency is a hallmark of Arctic Active Cooling Units, making them an excellent choice for businesses seeking sustainable practices without compromising performance. These monoblock refrigeration units utilize state-of-the-art insulation materials and eco-friendly refrigerants that significantly reduce energy consumption compared to older models. By optimizing energy use, businesses can lower operational costs while contributing to environmental sustainability.

Moreover, many models come equipped with smart technology that monitors energy usage in real-time, allowing operators to identify inefficiencies quickly. This level of insight helps businesses implement proactive measures to enhance their overall energy efficiency further. In an age where sustainability matters more than ever, choosing an efficient monoblock cooler can be both an economical and eco-friendly decision.

Applications in Commercial Cold Storage

The versatility of Arctic Active Cooling Units makes them ideal for various applications within commercial cold storage environments. From grocery stores stocking perishable goods to restaurants requiring precise temperature control for ingredients, these monoblock refrigeration units cater to diverse needs effectively. Their ability to maintain consistent temperatures helps prevent spoilage and waste while ensuring food safety standards are upheld.

In addition to traditional food storage applications, these cooling units have found their niche in specialized sectors such as floristry and pharmaceuticals where specific temperature ranges are crucial for product integrity. The adaptability of the monoblock refrigeration system allows it to be customized according to specific requirements across industries—making it a valuable asset for any business focused on quality preservation.

As we continue exploring the features of Arctic Active Cooling Units, it's clear they represent the future of efficient cold storage solutions—combining advanced technology with sustainability efforts while meeting diverse application needs head-on.

Real-World Applications of Monoblock Refrigeration Units

Monoblock refrigeration units are increasingly becoming the go-to solution for various industries that require reliable and efficient cooling systems. Their compact design and energy efficiency make them suitable for a range of applications, from floral shops to grocery stores and restaurants. Understanding how these systems function in real-world scenarios helps to appreciate their versatility and effectiveness.

Use in Florists and Wholesale Flower Markets

In florists and wholesale flower markets, maintaining a consistent temperature is crucial for preserving the freshness of flowers. Monoblock refrigeration units provide an ideal solution with their ability to maintain precise temperature control, ensuring that blooms remain vibrant longer. What is a monoblock refrigeration system? It’s designed specifically to cater to such needs, offering reliable cooling without taking up too much space.

Florists often rely on monoblock coolers to create optimal environments for various flower types, from delicate orchids to hardy sunflowers. These units can be seamlessly integrated into display cases or storage areas, allowing florists to showcase their products while keeping them fresh. Additionally, the energy efficiency of these systems means lower operational costs—a win-win for business owners.

Monoblock Systems in Grocery Stores

Grocery stores are bustling environments where maintaining food safety is paramount; this is where monoblock refrigeration units shine again! These systems are perfect for keeping perishable goods like dairy products, meats, and vegetables at safe temperatures throughout the day. With their compact design and powerful cooling capabilities, what is a monoblock compressor? It works tirelessly behind the scenes to ensure that food stays fresh from delivery until purchase.

In grocery stores, monoblock coolers can be strategically placed in aisles or near checkout counters as part of merchandising displays. This not only enhances product visibility but also ensures that items remain at optimal temperatures without requiring extensive installation work typically associated with larger refrigeration setups. By utilizing these efficient systems, grocery store owners can optimize both space and energy consumption while enhancing customer satisfaction through fresher produce.

Cold Storage Solutions for Restaurants

Restaurants face unique challenges when it comes to food storage; they need quick access to ingredients while ensuring everything remains fresh until it's time for cooking or serving guests. Enter the monoblock refrigeration unit—an essential ally in any restaurant's kitchen arsenal! With their ability to maintain stable temperatures under varying loads, what are the four types of refrigeration systems? Monoblocks stand out due to their efficiency and ease of use compared to traditional options.

From walk-in refrigerators stocked with meats and vegetables to under-counter coolers holding sauces and garnishes close at hand, these versatile units fit seamlessly into any restaurant layout. The compact nature of a monoblock cooler allows chefs easy access without compromising on storage capacity or temperature control—what is a monoblock cooler if not an embodiment of convenience? As restaurants continue prioritizing sustainability alongside quality ingredients, adopting energy-efficient solutions like monoblocks becomes increasingly vital.

Conclusion

As we wrap up our exploration of monoblock refrigeration systems, it’s clear that these units are not just a passing trend in the world of cold storage. The future of monoblock refrigeration technology looks promising, with advancements that will enhance efficiency and sustainability. With ongoing innovations, businesses can expect even more reliable and effective solutions to their cooling needs.

The Future of Monoblock Refrigeration Technology

Looking ahead, the evolution of what is a monoblock refrigeration system? is likely to include smart technology integration, allowing for real-time monitoring and adjustments based on environmental conditions. This means that businesses utilizing a monoblock refrigeration unit could achieve unprecedented levels of energy efficiency and operational control. Additionally, we may see further advancements in materials and design that make these systems even more compact and powerful.

Essential Considerations for Cold Storage Businesses

When considering what is a monoblock cooler? for your operations, there are several essential factors to keep in mind. First, evaluate the specific cooling requirements based on the products being stored—different items may require different temperatures or humidity levels. Furthermore, understanding what are the four types of refrigeration systems? can help you make an informed decision about whether a monoblock refrigeration unit is indeed the best choice for your business needs.

Enhancing Efficiency with Advanced Refrigeration Solutions

To truly enhance efficiency with advanced refrigeration solutions, businesses should prioritize energy-saving technologies found in modern monoblock compressors. These compressors offer significant advantages over traditional models by reducing power consumption while maintaining optimal performance levels. By investing in a high-quality monoblock refrigeration unit and staying updated on industry trends, cold storage facilities can ensure they remain competitive in an ever-evolving market.