Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the bustling world of food service and storage, commercial refrigeration equipment for eggs, produce, and dairy uses plays a pivotal role in ensuring the freshness and safety of perishable goods. Understanding the specific refrigeration needs for various products is essential for businesses aiming to maintain quality while minimizing waste. As we dive into this topic, we'll explore the critical aspects of temperature control and the various equipment types available to meet these demands.

Understanding Commercial Refrigeration Needs

Different food items have unique refrigeration requirements that must be addressed to preserve their integrity. For instance, eggs need consistent cooling to prevent spoilage, while produce requires humidity control to stay crisp and fresh. Dairy products demand precise temperature management to avoid bacterial growth, making it crucial for businesses to select suitable commercial refrigeration equipment tailored for eggs, produce, and dairy uses.

Importance of Proper Temperature Control

Maintaining proper temperature control is not just a matter of preference; it’s vital for food safety and quality assurance. Fluctuations in temperature can lead to spoilage or contamination, resulting in financial losses and potential health risks. By investing in reliable systems that feature components like condensers in AC units, evaporator coils, air conditioner coils, and expansion valves, businesses can ensure their products remain safe from harm.

Overview of Equipment Types

The landscape of commercial refrigeration equipment is diverse and tailored to meet varying needs across different sectors. From walk-in coolers designed for bulk storage of produce to specialized units that cater specifically to dairy or egg preservation—each type has its own set of features that enhance efficiency. Understanding these options enables businesses to make informed decisions about which air cooling evaporators or air conditioner expansion valves will best suit their operational requirements.

Choosing the Right Refrigeration Equipment

When it comes to commercial refrigeration, selecting the right equipment is crucial for maintaining freshness and quality across various food products. Different items, such as eggs, produce, and dairy, each have unique temperature requirements that must be met to ensure safety and extend shelf life. Understanding these needs will guide businesses in investing in the best commercial refrigeration equipment for eggs, produce, and dairy uses.

Exploring Commercial Refrigeration Equipment for Eggs

Eggs are particularly sensitive to temperature fluctuations; therefore, specialized commercial refrigeration equipment for eggs is essential. These units typically feature advanced air cooling evaporators designed to maintain a consistent temperature throughout storage. By incorporating a reliable condenser in AC systems within these refrigerators, businesses can ensure optimal cooling efficiency while minimizing energy consumption.

When selecting refrigeration solutions for eggs, consider models that utilize an air conditioner coil with precise temperature control capabilities. This ensures that the interior remains cool enough to prevent spoilage while also allowing easy access for staff during busy hours. Furthermore, regular maintenance of components like the evaporator coil can significantly enhance performance and longevity.

In addition to standard cooling features, some modern egg refrigeration units come equipped with smart technology that monitors conditions in real-time. This not only alerts users if temperatures deviate but can also integrate with other systems via an air conditioner expansion valve for more efficient operation. Investing in such technology helps safeguard product integrity while optimizing energy use.

Selecting Refrigeration Solutions for Produce

Produce requires specific humidity levels alongside cool temperatures to stay fresh longer; thus, choosing the right commercial refrigeration equipment is vital. Solutions designed specifically for fruits and vegetables often incorporate humidity controls along with efficient evaporator coils that circulate cold air evenly throughout the unit. This combination helps reduce spoilage rates significantly compared to traditional cooling methods.

Moreover, when evaluating options for produce storage, look out for systems featuring high-quality condensers in AC configurations that support rapid cooling without compromising energy efficiency or product quality. An effective air conditioning system ensures uniform airflow around stored items—crucial when dealing with delicate produce that may bruise easily if not handled properly.

Another key factor is ensuring your chosen solution includes an expansion valve capable of adjusting refrigerant flow based on current conditions inside the unit. This adaptability allows businesses to maintain ideal environments even during peak operating hours when demand fluctuates dramatically—making it easier than ever to keep fruits and vegetables at their freshest!

Effective Options for Dairy Products

Dairy products are highly perishable and require strict temperature control; hence selecting appropriate commercial refrigeration equipment is non-negotiable here too! Dairy-specific units often feature enhanced insulation alongside robust condenser designs tailored specifically toward maintaining low temperatures consistently over time—essential elements when safeguarding against bacterial growth.

For optimal results in dairy storage applications, consider models equipped with advanced aircon evaporator coils which promote consistent cold airflow throughout every corner of the refrigerator space—ensuring no hot spots develop where bacteria might thrive! Additionally, integrating smart sensors into these systems can help track temperatures continuously; any deviations from set parameters trigger alerts so corrective actions can be taken immediately.

Finally yet importantly: investing in energy-efficient technologies like variable-speed compressors or intelligent expansion valves will not only save money on utility bills but also contribute positively towards sustainability goals within your business operations! With effective options available today tailored specifically toward dairy products’ unique needs—the path forward has never been clearer!

Key Components of Refrigeration Systems

Understanding the key components of refrigeration systems is crucial for optimizing commercial refrigeration equipment for eggs, produce, and dairy uses. Each part plays a vital role in maintaining the desired temperature and ensuring that perishable items remain fresh and safe for consumption. In this section, we will explore the roles of the condenser in AC systems, the functionality of the evaporator coil, and delve into the workings of the air conditioner coil.

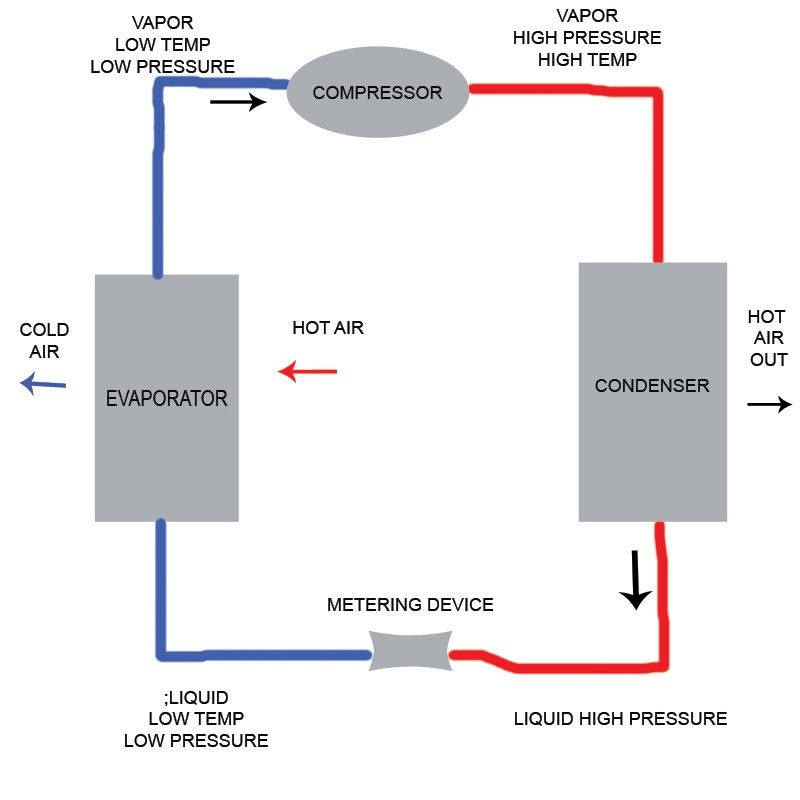

Role of the Condenser in AC Systems

The condenser in AC systems serves as a pivotal player in heat exchange processes. It takes on the task of expelling heat absorbed from inside a refrigerated space to the outside environment, transforming refrigerant from gas back into liquid form. This process is essential for maintaining optimal temperatures within commercial refrigeration equipment for eggs, produce, and dairy uses; without an efficient condenser, temperature control would falter.

Moreover, condensers come in various designs—air-cooled or water-cooled—each suited to different applications and environments. For instance, air cooling evaporators are often favored in settings where water access is limited or costly. The efficiency of your condenser directly impacts energy consumption; thus investing in high-quality units can significantly enhance overall system performance.

Functionality of the Evaporator Coil

The evaporator coil is another critical component that works hand-in-hand with both condensers and air conditioning systems to ensure effective cooling. Located inside refrigerated spaces, this coil absorbs heat from surrounding air or products—like eggs or dairy—allowing them to cool down efficiently. As warm air passes over it, refrigerant within the evaporator coil absorbs heat and transforms into gas; this process cools down your stored items effectively.

In commercial refrigeration equipment for eggs, produce, and dairy uses specifically designed coils can optimize airflow while maximizing cooling efficiency. Regular maintenance ensures that these coils remain free from dust and debris that could hinder their performance—a clean evaporator coil translates to lower energy costs! Moreover, understanding how your aircon evaporator coil operates can help you troubleshoot issues before they escalate into costly repairs.

Understanding the Air Conditioner Coil

The air conditioner coil serves as a bridge between cooling mechanisms and indoor environments by facilitating heat exchange during refrigeration cycles. Essentially divided into two types—the evaporator coil (inside) and condenser coil (outside)—these components work together seamlessly to provide consistent cooling across various applications including commercial refrigeration equipment for eggs, produce, and dairy uses.

When discussing an air conditioner expansion valve's role alongside these coils, it’s important to note how they regulate refrigerant flow based on temperature changes detected by sensors within these coils. This regulation ensures that each component operates at peak efficiency while adapting to varying demands throughout day-to-day operations—an essential feature when dealing with perishable goods! By grasping how these elements interact within your system's framework will empower you with knowledge on enhancing its longevity.

Innovative Refrigeration Technologies

In the ever-evolving world of commercial refrigeration, innovation plays a critical role in enhancing efficiency and performance. Technologies like air cooling evaporators and advanced expansion valves are revolutionizing how businesses manage temperature-sensitive products, particularly in industries dealing with eggs, produce, and dairy uses. By understanding these technologies, companies can make informed decisions that lead to improved energy savings and product quality.

Benefits of Air Cooling Evaporators

Air cooling evaporators are becoming increasingly popular in commercial refrigeration settings due to their efficiency and versatility. These systems utilize an air conditioner coil design that promotes optimal heat exchange while maintaining the necessary temperatures for sensitive goods such as eggs, produce, and dairy products. By ensuring that the evaporator coil operates effectively, businesses can reduce energy consumption while extending the shelf life of their perishable items.

Moreover, air cooling evaporators often come equipped with advanced features that allow for better airflow management. This not only helps maintain consistent temperatures but also minimizes hotspots that could jeopardize food safety. In a world where consumer expectations for freshness continue to rise, investing in high-quality air cooling evaporators is a smart move for any business looking to stay competitive.

Efficient Use of Air Conditioner Expansion Valves

The air conditioner expansion valve is another crucial component in modern refrigeration systems that enhances overall efficiency. By regulating the flow of refrigerant into the evaporator coil, these valves ensure optimal temperature control within commercial refrigeration equipment for eggs, produce, and dairy uses. When used correctly, an air conditioner expansion valve can significantly improve system performance by preventing refrigerant flooding or starvation.

Furthermore, employing efficient expansion valves allows businesses to achieve precise temperature regulation without unnecessary energy expenditure. This is particularly important when dealing with delicate items like dairy products or fresh produce that require consistent conditions to remain viable. With advancements in technology leading to more reliable expansion valves on the market today, companies have greater opportunities than ever before to optimize their refrigeration systems.

Significance of the Expansion Valve in Systems

The significance of the expansion valve cannot be overstated when it comes to effective refrigeration systems design and operation. Acting as a bridge between high-pressure liquid refrigerant from the condenser in AC units and low-pressure gas entering the evaporator coil, this component plays a pivotal role in maintaining system balance and efficiency. Without a properly functioning expansion valve, even the best commercial refrigeration equipment for eggs would struggle to perform optimally.

Additionally, advancements have led to smarter expansion valves capable of adapting their performance based on real-time conditions within the system. This means businesses can benefit from enhanced energy savings while ensuring their perishable goods remain at ideal temperatures throughout storage and transport processes. As industries continue pushing towards sustainability goals, understanding how each component—especially the expansion valve—contributes to overall efficiency will be key for future success.

Energy Efficiency in Refrigeration

In the world of commercial refrigeration, energy efficiency is not just a trend; it's a necessity. Sustainable cooling solutions are vital for reducing operational costs and minimizing environmental impact. As businesses increasingly seek to optimize their refrigeration systems, understanding the importance of energy-efficient practices becomes paramount.

Importance of Sustainable Cooling Solutions

Sustainable cooling solutions are essential in today's eco-conscious market, especially for businesses dealing with commercial refrigeration equipment for eggs, produce, and dairy uses. These solutions not only help reduce energy consumption but also lower greenhouse gas emissions associated with traditional refrigeration methods. By investing in sustainable technologies like air cooling evaporators and advanced condenser in AC systems, companies can significantly enhance their operational efficiency while contributing positively to the environment.

Moreover, implementing sustainable practices can lead to substantial long-term savings on utility bills. For instance, using an air conditioner expansion valve helps regulate refrigerant flow efficiently, optimizing energy use throughout the system. As consumers become more aware of sustainability issues, businesses that prioritize eco-friendly refrigeration will likely gain a competitive edge.

Energy-Saving Features of Leading Brands

Leading brands in commercial refrigeration have recognized the demand for energy-saving features that cater specifically to eggs, produce, and dairy uses. Many manufacturers now incorporate advanced components such as high-efficiency evaporator coils and smart temperature control systems into their designs. These innovations ensure that products are stored at optimal temperatures while minimizing energy waste.

For example, some models utilize variable speed compressors paired with aircon evaporator coils to adjust cooling output based on real-time needs. This adaptability not only enhances performance but also decreases electricity consumption during off-peak hours. Additionally, many brands offer user-friendly interfaces that allow operators to monitor and manage energy usage effectively.

Investing in such leading brands can be a game-changer for businesses looking to improve their bottom line while maintaining high-quality storage conditions for sensitive items like dairy products or fresh produce.

Cost-Effective Practices for Businesses

Implementing cost-effective practices is crucial for businesses utilizing commercial refrigeration equipment for eggs, produce, and dairy uses. Regular maintenance checks on key components such as the condenser in AC units and expansion valves can prevent costly breakdowns and ensure optimal performance over time. Simple tasks like cleaning evaporator coils or ensuring proper airflow around units can make a significant difference in overall efficiency.

Moreover, training staff on best practices related to temperature monitoring helps maintain consistent conditions within refrigerated spaces—essentially making sure your air conditioning systems work smarter rather than harder! Using programmable thermostats allows businesses to set specific cooling schedules tailored to peak hours when demand is highest.

Finally, consider investing in insulation improvements around refrigerated areas; this simple upgrade can drastically reduce energy loss and enhance system performance over time—making your investment pay off sooner than you think!

Case Study: Arctic Active Cooling Solutions

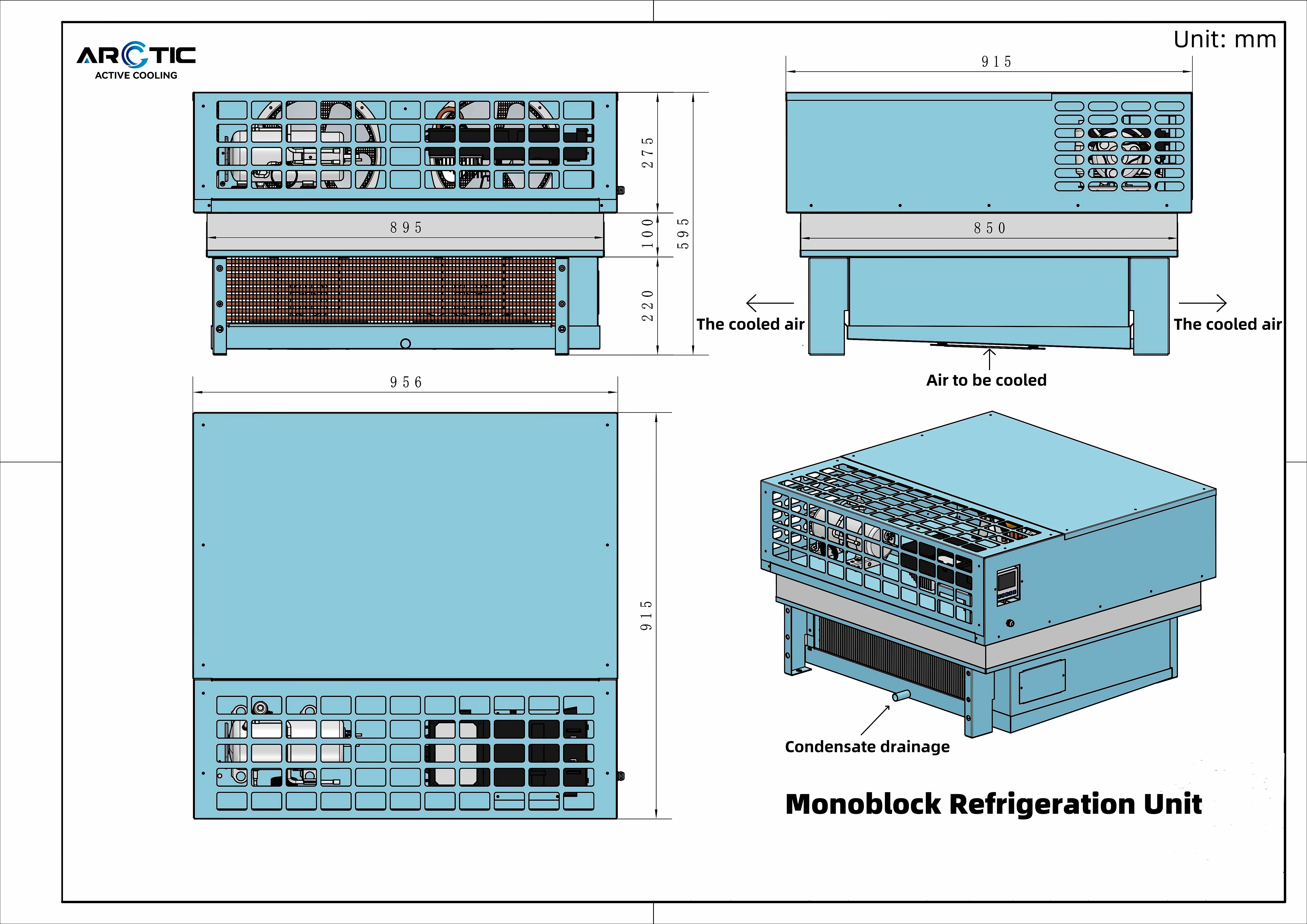

Arctic Active Cooling Solutions has established itself as a leader in the realm of commercial refrigeration equipment for eggs, produce, and dairy uses. Their innovative designs focus on efficiency and reliability, ensuring that temperature-sensitive products are stored under optimal conditions. One standout product is the top-mounted monoblock refrigeration unit, which integrates various components to provide seamless cooling solutions.

Overview of the Top-Mounted Monoblock Refrigeration Unit

The top-mounted monoblock refrigeration unit is a compact powerhouse that centralizes all necessary components for effective cooling. This unit typically houses the condenser in AC systems, evaporator coil, air conditioner coil, and expansion valve within a single structure, simplifying installation and maintenance. By utilizing an air cooling evaporator system, it ensures even temperature distribution while maximizing energy efficiency.

This design not only saves space but also enhances performance by reducing the length of refrigerant lines needed between components. The integration of an air conditioner expansion valve allows for precise control over refrigerant flow, optimizing cooling capacity based on real-time needs. Overall, this monoblock solution represents a significant advancement in commercial refrigeration technology.

Applications in Storing Eggs, Produce, and Dairy

Arctic's top-mounted monoblock refrigeration unit is versatile enough to cater to various commercial refrigeration equipment for eggs, produce, and dairy uses. For eggs specifically, maintaining consistent temperatures is crucial to prevent spoilage; this unit excels at keeping egg storage areas cool without fluctuations that could compromise quality. Similarly, when it comes to fresh produce like fruits and vegetables, precise temperature control helps extend shelf life while preserving flavor and texture.

Dairy products also benefit immensely from this type of refrigeration system; milk and cheese require strict adherence to cold storage protocols to remain safe for consumption. The combination of an efficient evaporator coil with advanced sensors ensures that these sensitive items stay within their ideal temperature ranges at all times. Thus, whether it’s eggs or artisanal cheeses being stored—this unit stands out as a reliable choice across multiple food sectors.

Real-World Success Stories of Commercial Use

Numerous businesses have turned to Arctic’s solutions for their commercial refrigeration needs with resounding success stories emerging from various sectors. For instance, a local farm known for its organic eggs reported significant improvements in freshness after installing the top-mounted monoblock refrigeration unit; they noted reduced spoilage rates thanks to its effective management of temperature fluctuations using its aircon evaporator coil technology.

Another case involved a bustling urban grocery store that needed reliable storage for both produce and dairy products; after implementing this system with an air conditioning expansion valve feature tailored specifically for high-demand environments—they experienced enhanced inventory turnover rates due to improved product quality over time.

These real-world applications not only highlight the effectiveness of Arctic Active Cooling Solutions but also underscore how critical proper commercial refrigeration equipment for eggs, produce, and dairy uses can be in maintaining food safety standards while maximizing operational efficiency.

Conclusion

In conclusion, the world of commercial refrigeration is a dynamic landscape that requires attention to detail and an understanding of specific needs. From maintaining optimal temperatures for perishable goods like eggs, produce, and dairy to implementing the latest technologies, businesses must prioritize efficiency and sustainability. With the right practices and equipment, companies can ensure their refrigeration systems operate at peak performance.

Best Practices for Maintaining Refrigeration Equipment

To keep your commercial refrigeration equipment for eggs, produce, and dairy uses running smoothly, regular maintenance is essential. This includes checking key components like the condenser in AC systems and ensuring that the evaporator coil is clean and functioning properly. Additionally, monitoring the air conditioner coil for any signs of wear or inefficiency can prevent costly breakdowns down the line.

Another best practice involves keeping an eye on your expansion valve settings; they play a critical role in regulating refrigerant flow. Regularly inspecting air cooling evaporators can also help maintain optimal performance by ensuring they are free from dust or debris. By adhering to these maintenance tips, businesses can extend the lifespan of their refrigeration equipment while maximizing energy efficiency.

Future Trends in Commercial Cooling Solutions

Looking ahead, several trends are shaping the future of commercial cooling solutions. Innovations such as smart refrigeration systems equipped with advanced sensors will allow businesses to monitor temperatures remotely and receive alerts when issues arise—keeping eggs, produce, and dairy at perfect temperatures without constant oversight. Moreover, developments in eco-friendly refrigerants will likely become more prevalent as sustainability becomes a priority across industries.

Additionally, advancements in air conditioner expansion valves will enhance system efficiency by improving temperature control during varying load conditions. The integration of IoT technology into aircon evaporator coils could revolutionize how businesses manage their cooling needs by providing real-time data analytics. These trends not only promise better performance but also contribute to reduced operational costs over time.

Final Thoughts on Refrigeration Efficiency

Ultimately, achieving refrigeration efficiency isn't just about choosing the right commercial refrigeration equipment for eggs, produce, and dairy uses; it's about understanding how each component interacts within a system. The condenser in AC units plays a vital role alongside the evaporator coil to ensure effective heat exchange processes occur seamlessly. By focusing on these elements—including proper function of expansion valves—businesses can significantly enhance their overall cooling strategies.

As we embrace new technologies like air cooling evaporators and smarter controls for air conditioning systems, it’s crucial to remain adaptable to changes within this industry landscape. The future is bright for those who prioritize energy-efficient practices while staying informed about emerging trends in commercial refrigeration solutions. In doing so, companies not only protect their products but also contribute positively toward environmental sustainability.