Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the bustling world of logistics and storage, maintaining optimal temperatures within warehouses is crucial. Effective warehouse cooling systems not only protect valuable inventory but also enhance operational efficiency. As summer approaches, understanding the nuances of warehouse cooling becomes even more essential for businesses aiming to mitigate heat-related challenges.

Understanding the Importance of Warehouse Cooling

Warehouse cooling systems play a pivotal role in preserving perishable goods, sensitive electronics, and various other items that require specific temperature conditions. The best warehouse cooling systems ensure that products remain in peak condition while minimizing spoilage and waste. Furthermore, efficient cooling solutions can lead to significant cost savings by reducing energy consumption and prolonging equipment lifespan.

Key Components of Effective Cooling Systems

To achieve optimal performance, effective cooling systems must incorporate several key components: insulation, airflow management, and temperature control mechanisms. Insulation helps maintain consistent temperatures by preventing heat infiltration from outside sources. Meanwhile, proper airflow management ensures that cool air circulates evenly throughout the space, while advanced temperature control technologies allow for precise monitoring and adjustments.

Common Challenges in Summer Cooling

As temperatures soar during summer months, warehouses face unique challenges in maintaining adequate cooling levels. Increased humidity can strain traditional systems and lead to inefficiencies or even equipment failure if not managed properly. Additionally, the rising costs associated with energy consumption make it vital for warehouse operators to explore innovative solutions like evaporative cooling systems for warehouses or consider how to cool a warehouse without AC.

The Best Warehouse Cooling Systems

Comparing Traditional vs. Innovative Solutions

Traditional warehouse cooling systems often rely on conventional air conditioning units, which can be energy-intensive and costly to operate over time. On the other hand, innovative solutions like evaporative cooling systems for warehouses are gaining popularity due to their efficiency and lower operational costs. By comparing these approaches, businesses can determine which option aligns best with their needs and budget constraints.

Innovative solutions frequently incorporate advanced technology such as smart sensors that adjust cooling based on real-time conditions—something traditional systems often lack. This adaptability not only enhances energy efficiency but also optimizes cooling performance across various warehouse sizes, including small warehouse cooling systems where space is at a premium. Ultimately, choosing between traditional and innovative systems requires weighing factors like cost-effectiveness, environmental impact, and operational flexibility.

Benefits of Evaporative Cooling Systems for Warehouses

Evaporative cooling systems for warehouses have emerged as a game-changer in temperature regulation during hot months. These systems work by using water evaporation to cool incoming air, making them particularly effective in dry climates where humidity levels are low. Not only do they use significantly less energy compared to industrial air conditioners for warehouses, but they also provide a more eco-friendly alternative that reduces carbon footprint.

Another major advantage of evaporative cooling is its ability to maintain optimal humidity levels while lowering temperatures—a critical factor in preserving sensitive products like food or pharmaceuticals stored in warehouses. Additionally, these systems can be easily scaled or adapted for small warehouse cooling systems without requiring extensive modifications or investments in infrastructure upgrades. The combination of efficiency and sustainability makes evaporative coolers an attractive choice for many businesses looking to enhance their operations.

Factors Affecting Warehouse Cooling Systems Cost

Understanding warehouse cooling systems cost involves examining various components that contribute to overall expenses—from initial installation fees to ongoing maintenance requirements. Traditional air conditioning units typically come with higher upfront costs due to their complexity and installation demands; however, their longevity may offset some of these expenses over time if maintained properly.

Conversely, innovative options like evaporative coolers often have lower initial investment costs but may require more frequent maintenance checks depending on usage patterns and environmental conditions—particularly important when considering how to cool a warehouse without AC effectively during peak summer months. Other factors influencing costs include the size of the facility, local climate conditions affecting system performance, and potential energy savings from efficient technologies that could reduce long-term utility bills.

Ultimately, evaluating all these factors will help businesses choose the best warehouse cooling system that fits both their budgetary constraints and operational needs while ensuring optimal climate control year-round.

Small Warehouse Cooling Systems

Efficient Options for Limited Spaces

For small warehouses, opting for evaporative cooling systems can be a game-changer. These systems utilize water evaporation to cool air, making them cost-effective and energy-efficient alternatives, especially in dry climates. Additionally, portable air conditioning units can provide flexible cooling options without the need for extensive installation processes.

Another great option is utilizing ceiling fans or high-velocity fans to promote air circulation throughout the space. This not only helps cool down areas but also enhances comfort levels for employees working in confined spaces. By combining these methods with proper insulation, you can maximize your small warehouse cooling systems' effectiveness while keeping costs low.

How to Cool a Warehouse Without AC

Cooling a warehouse without AC may seem daunting, but it's entirely feasible with the right strategies in place. First off, consider using natural ventilation techniques by opening windows and doors during cooler hours to allow fresh air in and hot air out. This method works particularly well if your location experiences significant temperature drops at night.

Implementing shading solutions such as awnings or reflective window films can also help reduce heat gain during peak sunlight hours. Additionally, using plants strategically around the warehouse can improve air quality and create a more pleasant working environment while contributing to natural cooling effects. These approaches not only save on warehouse cooling systems costs but also promote sustainability within your operations.

The Role of Industrial Air Conditioners

Industrial air conditioners play a pivotal role in maintaining optimal temperatures within larger or more demanding small warehouse environments where passive methods fall short. These robust units are designed specifically for heavy-duty use and can efficiently manage high heat loads associated with machinery or large inventories. Investing in an industrial air conditioner for a warehouse ensures that you have reliable climate control when it matters most.

Moreover, modern industrial air conditioners come equipped with advanced features such as programmable thermostats and energy-efficient technologies that help reduce overall energy consumption—making them an excellent long-term investment despite higher initial costs associated with traditional models. They also integrate seamlessly with existing warehouse cooling systems to provide comprehensive coverage across all areas of your facility.

In conclusion, whether you're exploring evaporative cooling systems for warehouses or considering how best to cool a space without AC, understanding your options will lead you toward effective solutions tailored for smaller environments—ensuring both comfort and efficiency are prioritized.

Evaluating Your Current Cooling Setup

When it comes to warehouse cooling systems, knowing when to evaluate and upgrade your setup can save you time, money, and headaches down the line. With the heat of summer bearing down, it’s crucial to ensure that your cooling systems are functioning optimally. This section will highlight signs that indicate you may need an upgrade, emphasize the importance of regular maintenance, and provide insights on measuring cooling efficiency.

Signs Your Warehouse Cooling Systems Need an Upgrade

If your warehouse feels more like a sauna than a storage facility during the summer months, it might be time to consider upgrading your warehouse cooling systems. Frequent breakdowns or repairs can signal that your existing system is reaching the end of its lifespan or is not suited for the space it serves. Additionally, if you notice inconsistent temperatures throughout different areas of your warehouse or if your energy bills have skyrocketed without explanation, these are clear indicators that it’s time to explore better options like evaporative cooling systems for warehouses or even an industrial air conditioner for warehouses.

Importance of Regular Maintenance

Regular maintenance of your cooling systems is not just a good idea; it's essential for ensuring longevity and efficiency in warehouse operations. By scheduling routine checks on your warehouse cooling systems, you can catch minor issues before they escalate into costly repairs or replacements. Moreover, a well-maintained system operates more efficiently, which can significantly lower warehouse cooling systems costs over time and keep energy consumption in check.

Measuring Cooling Efficiency

To truly understand how well your current setup is performing, measuring cooling efficiency should be at the forefront of your evaluation process. This involves analyzing factors such as temperature consistency across different areas and energy consumption relative to output effectiveness. By utilizing tools like temperature sensors and monitoring software designed specifically for industrial environments, you can gain valuable insights into how effectively you're using resources—helping you determine whether small warehouse cooling systems or alternative solutions might be necessary moving forward.

Innovative Technologies in Warehouse Cooling

In the ever-evolving landscape of warehouse management, innovative technologies play a crucial role in enhancing the efficiency of warehouse cooling systems. As businesses strive to optimize their operations, understanding and implementing these advanced solutions becomes essential for maintaining ideal temperature conditions. From smart cooling solutions to energy-efficient systems, the future of warehouse cooling is bright and promising.

Smart Cooling Solutions for Modern Warehouses

Smart cooling solutions are revolutionizing how warehouses manage temperature control. By integrating IoT technology and automation, these systems allow for real-time monitoring and adjustments based on current conditions, ensuring that the best warehouse cooling systems are always operating at peak efficiency. Not only do they enhance comfort for workers, but they also help preserve inventory quality by maintaining optimal climate conditions.

These smart systems can be programmed to respond dynamically to changes in occupancy levels or external weather conditions, making them particularly effective during hot summer months when traditional methods might struggle. Additionally, with features like predictive maintenance alerts, businesses can stay ahead of potential issues before they escalate into costly repairs or system failures. Ultimately, investing in these advanced technologies can significantly reduce warehouse cooling systems cost over time while improving overall operational efficiency.

The Impact of Temperature Sensors

Temperature sensors are a game-changer in the realm of warehouse cooling systems. By continuously monitoring temperature fluctuations throughout the facility, these sensors provide invaluable data that helps optimize cooling strategies and improve energy efficiency. When combined with automated controls, temperature sensors ensure that small warehouse cooling systems operate effectively without unnecessary energy expenditure.

Moreover, having precise temperature readings allows managers to identify hot spots within their warehouses that may require additional attention or alternative cooling methods—like evaporative cooling systems for warehouses—which can be more effective than standard air conditioning units in certain environments. These sensors not only enhance comfort levels but also minimize spoilage risks associated with sensitive products stored in varying temperatures. In essence, incorporating temperature sensors into your setup is a smart move toward optimizing your entire warehouse's climate control strategy.

Energy-efficient Cooling Systems

Energy-efficient cooling systems are becoming increasingly important as businesses look to reduce their carbon footprint while keeping costs manageable—especially when it comes to industrial air conditioners for warehouses that traditionally consume significant energy resources. These cutting-edge solutions employ advanced technologies such as variable speed drives and high-efficiency compressors that adapt their performance based on real-time needs rather than running at full capacity all day long.

In addition to reducing greenhouse gas emissions and energy consumption, energy-efficient options often qualify for rebates or incentives from local governments or utility companies looking to promote sustainability initiatives within their communities. This means not only lower operational costs but also an opportunity for warehouses to showcase their commitment to eco-friendly practices—a win-win situation! As companies continue searching for how to cool a warehouse without AC during extreme heat events or budget constraints, investing in energy-efficient alternatives will undoubtedly pay off both financially and environmentally.

Case Study: Arctic Active Cooling Solutions

In the world of warehouse cooling systems, Arctic Active Cooling Solutions stands out with its innovative technology designed to meet the unique demands of various storage environments. Their top-mounted monoblock refrigeration unit exemplifies how effective cooling can be achieved without compromising on space or efficiency. This case study delves into the standout features and applications of this system, providing insights into achieving optimal humidity and temperature control in commercial settings.

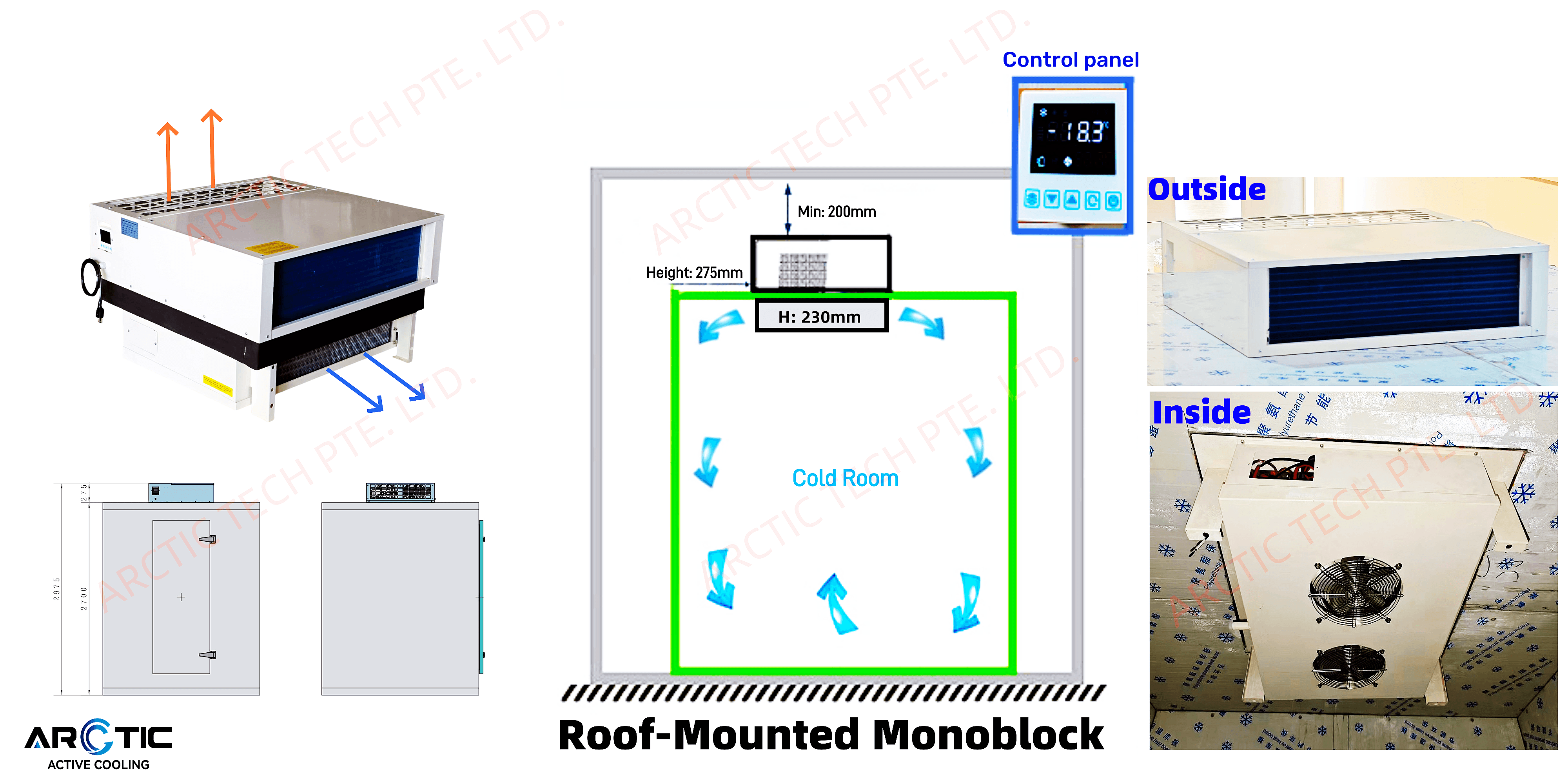

Features of the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit

The Arctic Active Cooling top-mounted monoblock refrigeration unit is engineered for maximum efficiency in warehouse cooling systems. With a compact design that minimizes floor space usage, it integrates seamlessly into existing structures while providing powerful cooling capabilities. Additionally, its energy-efficient operation not only helps reduce warehouse cooling systems cost but also contributes to a lower carbon footprint—an essential consideration for modern businesses aiming for sustainability.

Equipped with advanced temperature control mechanisms, this refrigeration unit ensures that products are kept at their ideal temperatures, crucial for maintaining product integrity in warehouses. The user-friendly interface allows for easy monitoring and adjustments, making it accessible even for those unfamiliar with complex industrial air conditioners for warehouses. Overall, its robust construction and reliable performance make it one of the best warehouse cooling systems available today.

Applications for Commercial Refrigerators and Freezers

Arctic's active cooling solutions are versatile enough to cater to various applications within commercial refrigerators and freezers. From food storage warehouses to pharmaceutical facilities requiring strict temperature controls, this system adapts effortlessly to different industries' needs. Its ability to maintain consistent temperatures makes it particularly suitable for small warehouse cooling systems where space is at a premium but reliability cannot be compromised.

Moreover, these units can effectively handle varying load conditions without sacrificing performance—an essential feature when dealing with fluctuating inventory levels typical in many warehouses. By employing evaporative cooling systems for warehouses alongside traditional refrigeration methods, businesses can create a comprehensive solution tailored specifically to their operational requirements while optimizing costs.

Achieving Optimal Humidity and Temperature

Achieving optimal humidity and temperature within warehouse settings is critical—not just for preserving goods but also for ensuring employee comfort during hot summer months. The Arctic Active Cooling unit excels in this regard by utilizing sophisticated sensors that monitor environmental conditions continuously. This real-time data allows operators to make informed decisions about how best to cool a warehouse without AC or enhance existing air conditioning setups.

Furthermore, proper humidity control prevents spoilage and extends product shelf life significantly—a win-win situation when considering overall operational efficiency and profitability! By incorporating such advanced technologies into their infrastructure, companies can elevate their warehousing strategies while keeping an eye on future trends in warehouse cooling technologies.

Conclusion

In wrapping up our exploration of warehouse cooling systems, it's clear that optimizing these systems is not just a luxury but a necessity for maintaining efficiency and productivity. From understanding the importance of effective cooling to evaluating innovative technologies, businesses can significantly enhance their operations during the sweltering summer months. By implementing best practices and staying informed about future trends, warehouses can ensure they remain cool under pressure.

Best Practices for Summer Cooling Optimization

To achieve optimal performance from your warehouse cooling systems, consider adopting a multi-faceted approach that includes regular maintenance and efficient design strategies. First, ensure that all components are functioning properly—this might mean checking filters in industrial air conditioners or inspecting evaporative cooling systems for warehouses. Additionally, investing in insulation and strategically placing fans can help distribute cool air more evenly throughout the space.

Another best practice involves utilizing temperature sensors to monitor conditions continuously; this allows you to make real-time adjustments to your cooling strategy. For those looking into small warehouse cooling systems, consider options like portable air conditioning units or misting fans as effective alternatives to traditional setups. Lastly, don't overlook the cost-effectiveness of using natural ventilation methods—learning how to cool a warehouse without AC can also save you money while keeping temperatures manageable.

Future Trends in Warehouse Cooling Technologies

The landscape of warehouse cooling systems is rapidly evolving with advancements in technology paving the way for smarter solutions. One exciting trend is the integration of IoT devices that enable real-time monitoring and control over temperature settings—this means you can adjust your industrial air conditioner for warehouses remotely! Moreover, energy-efficient models are becoming more prevalent as businesses seek sustainable options that reduce their carbon footprint.

Another forward-thinking approach involves utilizing renewable energy sources such as solar panels to power evaporative cooling systems for warehouses. This not only lowers operational costs but also aligns with growing demands for environmentally friendly practices in logistics and warehousing sectors. As we look ahead, expect innovations like AI-driven predictive maintenance tools that will keep your warehouse running smoothly while optimizing energy consumption.

Enhancing Sustainability in Warehouse Operations

Sustainability is no longer just a buzzword; it’s becoming an essential part of operational strategies across industries—including warehouse management! To enhance sustainability through your warehouse cooling systems, focus on selecting energy-efficient models designed specifically for large spaces or small warehouse cooling systems tailored to fit limited areas without sacrificing performance. These choices not only lower electricity bills but also contribute positively to environmental efforts.

Moreover, consider implementing green building practices such as reflective roofing materials or installing green walls which naturally regulate temperature while improving indoor air quality. Remember that educating staff about proper usage and maintenance of these cooling systems can lead to significant reductions in energy waste over time. By embracing sustainable solutions now, companies position themselves favorably within an increasingly eco-conscious market landscape.