Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the world of meat storage, freshness is paramount. The quality of meat can greatly impact taste, safety, and overall customer satisfaction. This makes understanding the intricacies of meat cooler rooms essential for anyone involved in meat processing or retail.

Why Freshness Matters in Meat Storage

Freshness is not just a matter of preference; it’s crucial for food safety and quality control. When discussing what is cool room temperature for meat, maintaining the right conditions helps prevent spoilage and bacterial growth. Properly managed meat cold storage solutions ensure that meats remain safe to consume while retaining their flavor and texture.

Essential Features of Meat Cooler Rooms

A well-designed cold room for meat processing should incorporate features that facilitate optimal storage conditions. Key elements include precise temperature controls, efficient airflow systems, and adequate insulation to maintain consistent temperatures throughout the cooler space. Understanding what temperature should a cold room for meat be stored at is vital; typically, it ranges between 28°F to 32°F (-2°C to 0°C) to maximize freshness.

Understanding Optimal Cool Room Temperatures

To answer the question, What temperature should a meat cooler be? it’s important to recognize that different types of meats may require slightly varied conditions for optimal preservation. A consistent cool room temperature not only prolongs shelf life but also enhances flavor profiles in various cuts of meat. By investing in effective Meat Cold Room Solutions like the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit, businesses can achieve unparalleled reliability and efficiency in their cooling processes.

The Ideal Temperature for Meat Cooling

What is the Right Cool Room Temperature for Meat?

So, what is cool room temperature for meat? Ideally, meat cooler rooms should maintain temperatures between 28°F to 32°F (-2°C to 0°C) to ensure optimal preservation. This range inhibits bacterial growth while allowing the natural aging process to enhance flavor without compromising safety.

Maintaining this ideal temperature ensures that your meats remain juicy and tender, whether you're storing beef, pork, or poultry. It’s essential to regularly check these temperatures with reliable monitoring tools to avoid any unexpected fluctuations that could jeopardize your inventory. Remember, consistency is key; even a slight increase can lead to spoilage.

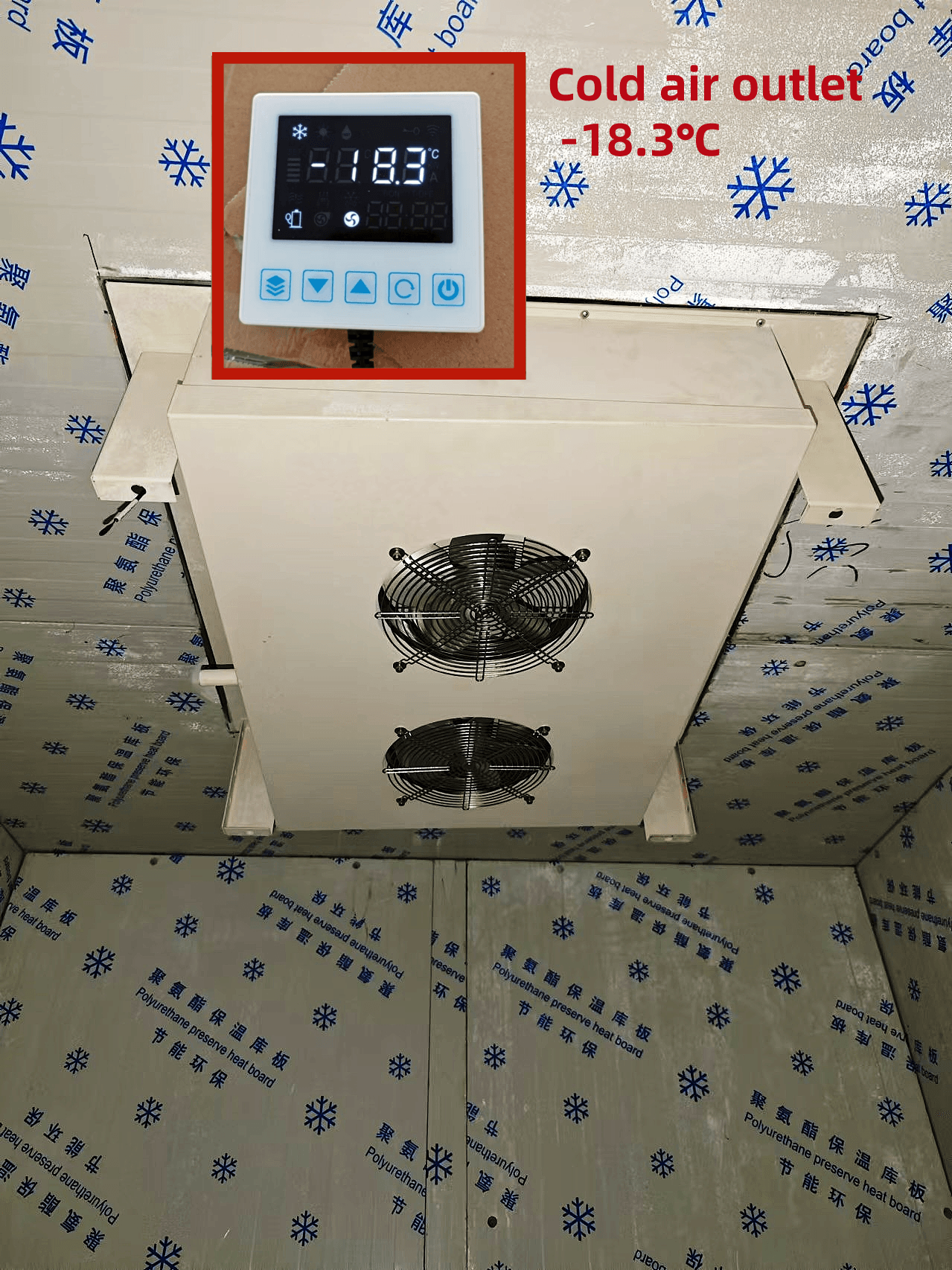

Maintaining Consistent Cold Room Temperatures

Maintaining consistent cold room temperatures involves more than just setting a thermostat and forgetting about it. Regular monitoring of your meat cooler rooms is vital; investing in quality temperature sensors can help you keep an eye on those critical degrees around the clock. If you’re wondering what temperature should a meat cooler be set at during peak usage times, sticking close to that ideal range will do wonders.

Another important aspect of maintaining these temperatures is understanding airflow within your cold room for meat processing. Proper ventilation helps distribute cool air evenly throughout the space, preventing hot spots where bacteria might flourish. Routine checks on equipment like the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit can also ensure optimal performance and reliability.

The Science Behind Meat Preservation

The science behind meat preservation hinges on controlling environmental factors like temperature and humidity in your meat cold storage solutions. When stored at optimal conditions in well-designed meat cooler rooms, meats undergo minimal microbial activity and enzymatic reactions that cause spoilage over time. This means fresher products not only look better but also taste better when they reach consumers’ plates.

Understanding how different types of meats respond to various storage conditions helps in selecting appropriate methods tailored specifically for each type—beef has different needs compared to poultry or fish! By employing effective practices within your cold room for meat processing, you can extend shelf life significantly while ensuring quality remains intact throughout its journey from farm to table.

Choosing the Right Equipment

When it comes to meat cooler rooms, selecting the right equipment is crucial for maintaining optimal freshness and safety. The equipment you choose not only influences the quality of meat storage but also impacts operational efficiency and energy consumption. With various Meat Cold Storage Solutions available, understanding what makes a cold room for meat processing effective is essential for any business in the industry.

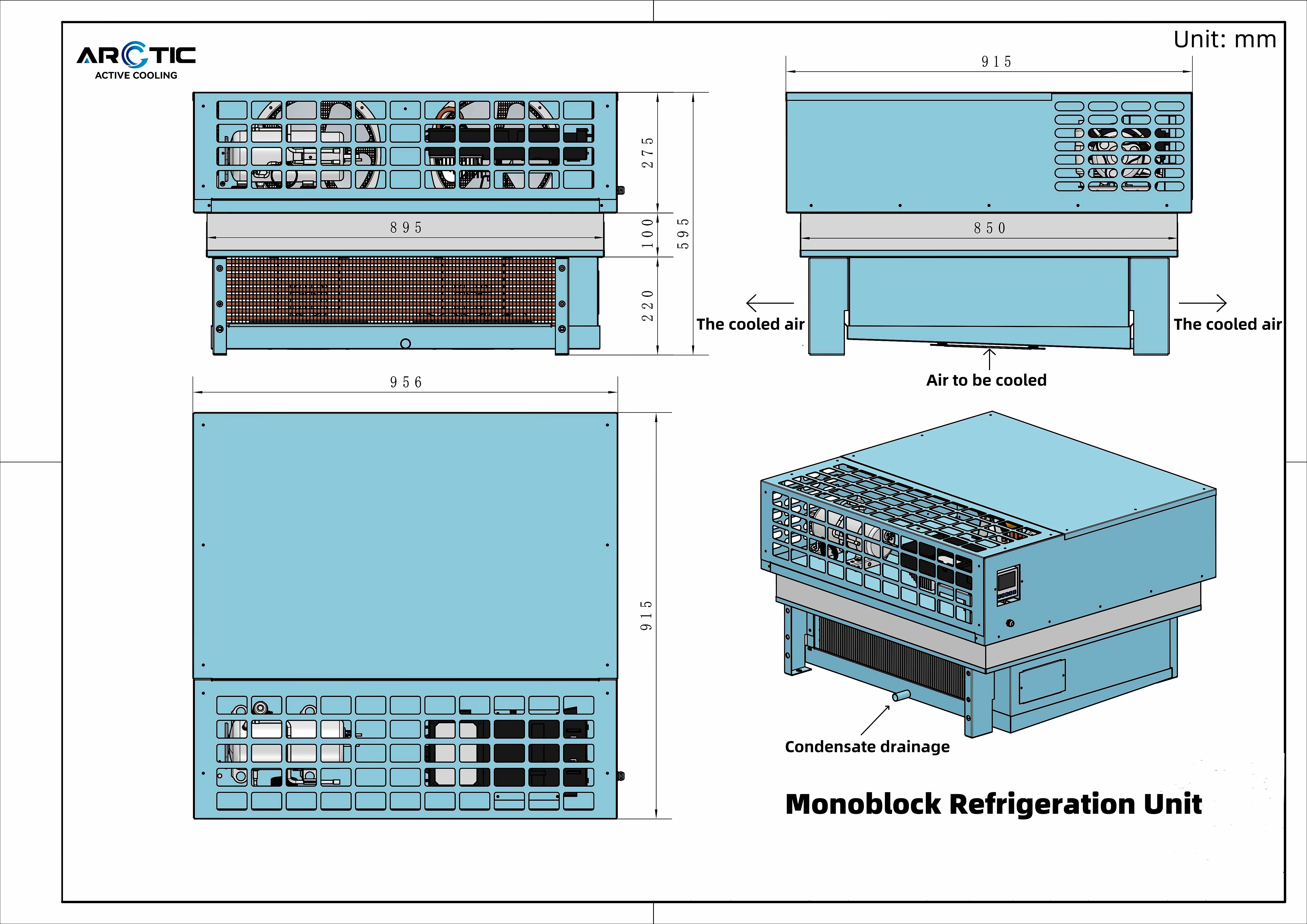

Benefits of the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit

The Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit stands out as an exceptional choice for meat cooler rooms due to its advanced cooling capabilities and robust design. This unit offers unparalleled efficiency and reliability, ensuring that your meats stay at the ideal temperature without breaking a sweat—literally! With its all-in-one design, this refrigeration unit simplifies installation and maintenance while providing consistent performance, making it a go-to solution for businesses looking to optimize their cold room for meat processing.

Moreover, this unit operates quietly and efficiently, which is a game-changer in busy environments where noise can be disruptive. Its ability to maintain stable temperatures means that you won’t have to worry about fluctuations that could compromise meat quality or safety. When asking What temperature should a cold room for meat be stored at?—the Arctic Active Cooling Unit ensures those standards are met effortlessly.

Evaluating Meat Cold Room Solutions

Choosing the right Meat Cold Room Solution goes beyond just picking a refrigeration unit; it involves evaluating several factors that contribute to effective meat storage. First off, consider energy efficiency—an essential aspect in today’s eco-conscious market where sustainability can influence purchasing decisions. Additionally, look into how well different units handle temperature consistency; after all, no one wants their meats flirting with spoilage due to erratic cooling.

Another crucial factor is scalability; as your business grows or changes needs arise, your equipment should adapt accordingly without requiring complete overhauls of existing systems. For example, if you're wondering What is cool room temperature for meat? then ensure your chosen system can easily adjust settings based on varying types of meats or seasonal demands. Ultimately, finding a solution that combines durability with flexibility will set you up for long-term success in managing your cold room for meat processing.

Essential Features for Effective Meat Storage

To ensure effective storage within your meat cooler rooms, certain features must be prioritized when selecting equipment and layout designs. First and foremost are reliable temperature controls; knowing what temperature should a meat cooler be set at can make or break your inventory’s longevity. Look for units equipped with advanced thermostats that provide real-time data on internal conditions so you can monitor fluctuations before they become problematic.

Airflow management is another critical feature; proper circulation helps maintain even temperatures throughout the space while preventing hotspots where bacteria might thrive—definitely not something you want when storing perishable goods! Additionally, consider shelving designs that maximize vertical space while allowing easy access to products; efficient organization not only saves time but also minimizes cross-contamination risks during handling.

In conclusion, investing in quality equipment like the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit alongside carefully evaluating other Meat Cold Storage Solutions will significantly enhance your operation's effectiveness and safety standards within these vital spaces.

Layout and Design of Meat Cooler Rooms

The layout and design of meat cooler rooms play a crucial role in ensuring optimal freshness and quality of stored products. An efficient cold room layout not only maximizes space but also facilitates easy access to different types of meats. By understanding the importance of airflow and proper storage techniques, businesses can create a meat cold room solution that meets their operational needs.

Creating Efficient Cold Room Layouts

When designing a meat cooler room, the first step is to consider how best to arrange the space for maximum efficiency. This involves strategically placing shelves and storage units to allow for easy movement while minimizing congestion. An efficient layout ensures that employees can quickly access various types of meats, which is essential when answering the question: what is cool room temperature for meat?

Additionally, incorporating designated areas for different types of meats—such as red meat, poultry, and seafood—can help prevent cross-contamination while maintaining ideal conditions. A well-thought-out design promotes organization and helps staff adhere to proper handling practices, ultimately contributing to better overall meat cold storage solutions.

Importance of Airflow in Meat Coolers

Airflow is a vital component in any cold room for meat processing; it directly affects the temperature consistency throughout the space. Proper circulation prevents hot spots that can lead to spoilage or uneven cooling, ensuring that all products are kept at their optimal temperatures. Understanding what temperature should a cold room for meat be stored at is important, but achieving consistent airflow makes this easier.

To promote effective airflow in your meat cooler rooms, consider using fans or vents strategically placed throughout the space. This will help maintain an even distribution of cool air while allowing moisture to escape—preventing condensation that could compromise product quality. Remember that without proper airflow management, even the best equipment like Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit may struggle to keep up with demands.

Optimizing Storage Space for Maximum Freshness

Maximizing storage space in your meat cooler rooms goes hand-in-hand with maintaining freshness and quality standards. Utilizing vertical shelving units and adjustable racks allows you to take advantage of every inch available while accommodating different sizes and cuts of meat effectively. When considering what temperature should a meat cooler be set at, remember that organized storage contributes significantly to maintaining those conditions.

In addition to vertical space optimization, labeling shelves according to product types or expiration dates can streamline inventory management processes within your cold room for meat processing. By implementing these strategies alongside robust monitoring tools—like those provided by Arctic Active Cooling—you can ensure your operations run smoothly while preserving the integrity of your products over time.

Monitoring and Maintenance Practices

Maintaining the ideal conditions in meat cooler rooms is pivotal for preserving the quality and safety of stored meats. Regular monitoring and maintenance practices ensure that your cold room operates efficiently, keeping temperatures stable and minimizing the risk of spoilage. In this section, we will explore essential tools for temperature monitoring, the importance of regular maintenance schedules, and effective strategies for responding to temperature fluctuations.

Essential Tools for Temperature Monitoring

To guarantee that your cold room for meat processing operates at optimal levels, investing in reliable temperature monitoring tools is a must. Digital thermometers with remote monitoring capabilities provide real-time data on what is cool room temperature for meat, allowing you to track changes promptly. Additionally, integrating alarms or alerts can notify you immediately if temperatures deviate from the desired range—critical information when managing meat cold storage solutions.

When considering what temperature should a cold room for meat be stored at, it's essential to maintain consistent readings throughout different sections of the cooler. Using multiple sensors can help achieve this goal by ensuring all areas are equally monitored. Ultimately, these tools not only enhance food safety but also extend the shelf life of various meats by maintaining ideal storage conditions.

Scheduling Regular Maintenance for Cold Rooms

Regular maintenance is crucial in ensuring that your meat cooler rooms function seamlessly over time. Establishing a routine schedule allows you to identify potential issues before they escalate into costly repairs or product loss due to improper cooling conditions. Key tasks include checking refrigerant levels, inspecting seals and insulation, and cleaning condenser coils—each essential in determining what temperature should a meat cooler be.

Furthermore, enlisting professionals who specialize in Meat Cold Room Solutions can streamline this process while ensuring compliance with health regulations. By prioritizing maintenance schedules, businesses can enjoy peace of mind knowing their investments are safeguarded against unexpected failures that could jeopardize product quality or safety.

Responding to Temperature Fluctuations

Despite best efforts in monitoring and maintenance practices, fluctuations in temperature may still occur within your cold room for meat processing due to various factors such as equipment failure or power outages. Being prepared with an action plan can mitigate potential losses when faced with these challenges effectively. First and foremost, having backup systems like portable refrigeration units can provide immediate support during emergencies.

In case of significant deviations from what is considered cool room temperature for meat, it’s crucial to assess whether any products have been compromised before deciding on their usability or disposal. Keeping thorough records of temperatures over time helps identify patterns that may indicate underlying issues needing attention—ultimately contributing to better management of your Meat Cold Storage Solutions.

Best Practices for Meat Cold Storage

When it comes to meat cold storage, adhering to best practices is essential for maintaining the freshness and safety of your products. Proper meat handling techniques, understanding shelf life, and efficient inventory management are key components that contribute to effective meat cooler rooms. By implementing these practices, businesses can ensure they are maximizing the benefits of their meat cold storage solutions.

Proper Meat Handling Techniques

Proper meat handling techniques are crucial in preventing contamination and spoilage in meat cooler rooms. Always wear gloves when handling raw meats and ensure that all surfaces and tools are sanitized before and after use. Additionally, it’s important to separate different types of meats during storage; this minimizes cross-contamination risks while also making sure that each type is stored at its appropriate temperature—what is cool room temperature for meat? Ideally, a cold room for meat processing should be maintained at temperatures between 28°F (-2°C) and 32°F (0°C).

Understanding the Shelf Life of Different Meats

Understanding the shelf life of different meats is vital for any business utilizing a cold room for meat processing. Each type of meat has its own recommended storage duration; for instance, beef can last up to three weeks when stored correctly in a well-maintained meat cooler, whereas poultry typically has a shorter lifespan of one week. Knowing these timelines allows businesses to optimize their inventory turnover while ensuring that they adhere to food safety guidelines.

Tips for Efficient Inventory Management

Efficient inventory management plays an integral role in maximizing the effectiveness of your meat cold storage solutions. Implementing a first-in-first-out (FIFO) system helps ensure older stock is used before newer deliveries arrive—this practice keeps your products fresh while reducing waste due to spoilage. Additionally, regularly monitoring temperatures inside your cold room can prevent unexpected fluctuations; remember, what temperature should a cold room for meat be stored at? Keeping those temperatures stable not only extends shelf life but also enhances overall product quality.

Conclusion

In summary, maintaining the right conditions in meat cooler rooms is essential for preserving quality and safety. The optimal cool room temperature for meat typically ranges between 28°F to 32°F (-2°C to 0°C), ensuring that your products remain fresh and safe for consumption. Understanding what temperature should a cold room for meat be stored at is crucial not only for compliance with health regulations but also for maximizing shelf life.

Recap of Meat Cooler Temperature Guidelines

To recap, the ideal temperature range in a meat cooler is vital for preventing spoilage and extending the shelf life of various meats. Regularly monitoring these temperatures helps ensure that your cold room remains within the recommended limits, which is typically around 32°F (0°C) or slightly lower. By adhering to these guidelines, businesses can effectively manage their inventory while providing top-quality products to customers.

Importance of Equipment in Meat Storage

The role of equipment in meat storage cannot be overstated; reliable refrigeration units are fundamental to maintaining proper conditions in cold rooms for meat processing. For instance, the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit offers advanced cooling solutions that are both efficient and sustainable, making it an excellent choice for businesses looking to optimize their operations. Investing in high-quality Meat Cold Storage Solutions ensures that you can maintain consistent temperatures while minimizing energy costs.

Future Innovations in Meat Cold Storage Solutions

Looking ahead, innovations in technology promise to enhance the efficiency and effectiveness of meat cold storage solutions even further. From smart monitoring systems that alert users about temperature fluctuations to energy-efficient refrigeration units like those from Arctic Active Cooling, the future holds exciting possibilities for improving meat preservation practices. As we embrace these advancements, we can expect better quality control and sustainability across all sectors involved in meat processing and storage.

[Image description=Meat cooler room with neatly arranged shelves filled with various cuts of fresh meat, digital thermometer displaying optimal temperature settings on wall, modern refrigeration unit visible], Image name=meat_cooler_room_overview, Alt tag=Efficient layout of meat cooler rooms ensuring freshness and safety