Introduction

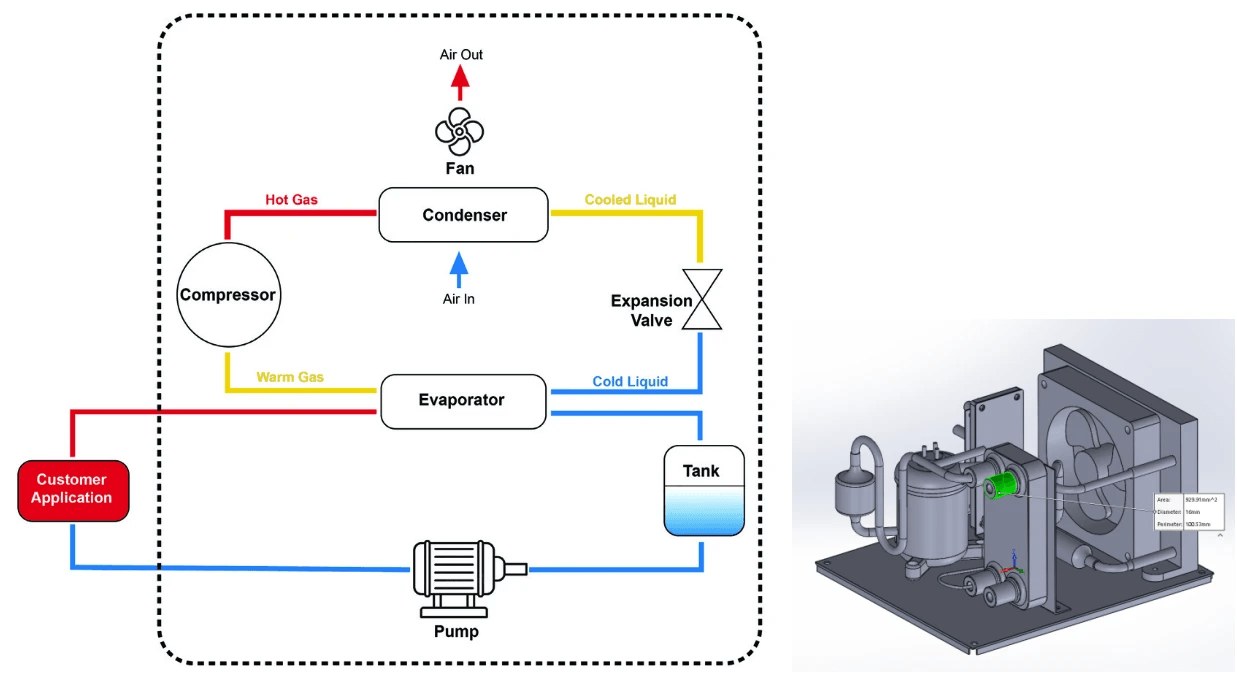

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the world of refrigeration, the oil separator plays a pivotal role in maintaining system efficiency and longevity. This unsung hero ensures that the oil circulates properly within the refrigeration compressor, preventing potential issues that could arise from excess oil in the evaporator refrigeration. By understanding its function, we can appreciate how an oil separator in refrigeration systems not only enhances performance but also safeguards against costly repairs.

Understanding the Role of Oil Separators

Oil separators are essential components designed to extract oil from refrigerant gases as they circulate through a refrigerator air conditioner. They work by utilizing various separation techniques to ensure that only clean refrigerant reaches critical components like the compressor and condenser. By effectively managing oil levels, these separators maintain optimal lubrication for moving parts, thereby improving overall system functionality.

How Oil Separators Enhance Efficiency

The integration of an oil separator in refrigeration systems significantly boosts efficiency throughout the air conditioning cycle. With proper separation, less energy is wasted on overcoming friction caused by excess oil buildup within the compressor and condenser. Consequently, this leads to a smoother operation of the basic refrigeration cycle, resulting in reduced energy consumption and improved cooling performance.

The Importance of Preventing Oil Flooding

Preventing oil flooding is crucial for maintaining a healthy refrigeration system; otherwise, it can lead to severe operational issues such as reduced cooling capacity or even complete system failure. When too much oil accumulates in areas like the evaporator refrigeration unit, it can hinder heat exchange processes and diminish overall effectiveness. Thus, incorporating an effective oil separator not only protects your investment but also ensures reliable performance over time.

The Functionality of Oil Separators

In the realm of refrigeration, understanding the functionality of oil separators is crucial for maintaining optimal performance. These components play a vital role in ensuring that oil does not interfere with the basic refrigeration cycle, thereby enhancing the efficiency of the refrigerator air conditioner. By effectively managing oil within the system, they contribute to a smoother operation and prolonging the lifespan of critical components like the refrigeration compressor.

Mechanism of Oil Separation

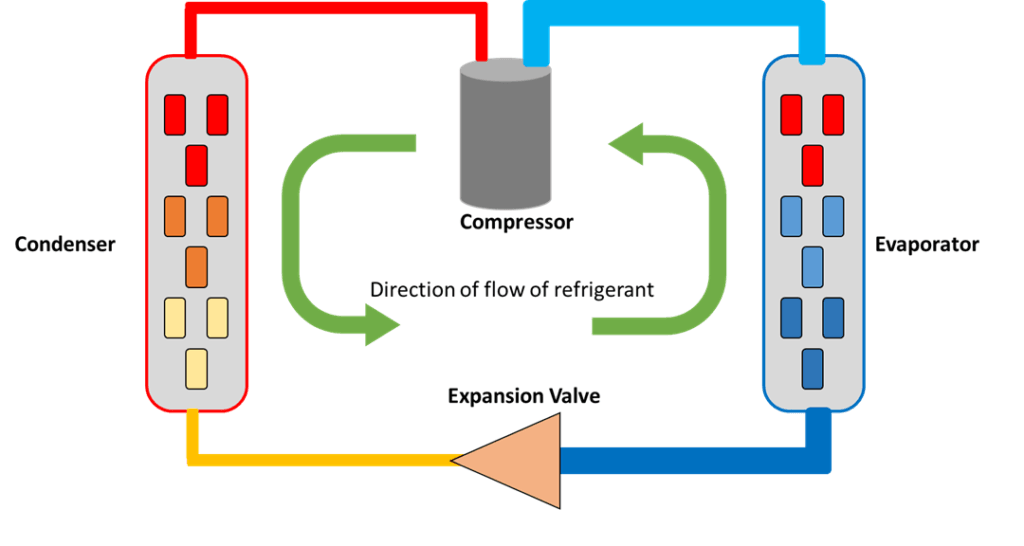

The mechanism of oil separation revolves around utilizing physical principles to segregate oil from refrigerant gases effectively. In an ideal scenario, when refrigerant circulates through the evaporator refrigeration unit, it carries along some lubricating oil from the compressor. An oil separator in refrigeration systems employs gravity or centrifugal force to separate this oil from the gas, allowing clean refrigerant to continue its journey while returning excess oil back to where it belongs—ensuring that both compressor and condenser function optimally.

Placement Within the Refrigeration System

Placement within a refrigeration system is paramount for an effective oil separator's performance. Typically installed after the compressor but before entering other components such as condensers and evaporators, it ensures that any entrained oil is removed early in the cycle. This strategic positioning prevents potential issues like flooding in evaporator refrigeration units and maintains efficiency throughout the air conditioning cycle.

Integration with Refrigeration Components

An efficient integration with various refrigeration components is essential for maximizing performance and reliability. The oil separator must work seamlessly with elements like compressors and condensers to ensure that only refrigerant enters these critical parts while returning separated oil back into circulation as needed. This harmonious relationship not only enhances overall system reliability but also significantly bolsters efficiency in cooling processes—essentially keeping your refrigerator air conditioner running like a well-oiled machine.

Benefits of an Oil Separator in Refrigeration

Incorporating an oil separator in the refrigeration system brings a host of benefits that significantly enhance performance and longevity. By effectively managing oil within the cycle, these separators not only improve efficiency but also safeguard essential components like the compressor and condenser. Let’s delve into how these benefits manifest in real-world applications.

Improved Efficiency of the Compressor

One of the most notable advantages of using an oil separator in refrigeration systems is the improved efficiency of the compressor. When excess oil circulates through the system, it can lead to poor heat exchange and reduced cooling capacity, ultimately straining your refrigerator air conditioner. By filtering out this excess oil, an oil separator allows for optimal function, ensuring that your refrigeration compressor operates smoothly and efficiently.

Moreover, a well-functioning compressor translates to lower energy consumption, which is not just good for your wallet but also for the environment. The basic refrigeration cycle thrives on efficiency; thus, maintaining ideal oil levels within this cycle is crucial for achieving peak performance. With enhanced efficiency comes less wear and tear on components, paving the way for a more reliable refrigeration system.

Increased Lifespan of Refrigeration Systems

An often-overlooked benefit of installing an oil separator in a refrigeration system is its ability to extend the lifespan of various components. Excessive oil can accumulate in critical areas like evaporator refrigeration units and lead to potential failures or costly repairs down the line. By maintaining balanced lubrication levels through effective separation techniques, these devices help ensure that both compressors and condensers can operate without undue stress.

Furthermore, when you reduce wear on these vital parts by utilizing an efficient oil separation process, you’re investing in long-term savings as well as reliability. The longer your equipment lasts without needing replacements or extensive maintenance, the more you save over time—both financially and operationally. In essence, integrating an oil separator contributes significantly to preserving your investment in a high-performing refrigeration system.

Enhanced Reliability of the Air Conditioning Cycle

Reliability is paramount when it comes to any air conditioning cycle; after all, nobody wants their fridge failing during a heatwave! An effective oil separator ensures that there’s minimal risk of issues arising from excessive lubrication entering key areas such as evaporators or compressors within your refrigerator air conditioner setup. This means fewer breakdowns and interruptions—music to any homeowner's ears!

Additionally, with less fluctuation in performance due to consistent lubrication levels maintained by an efficient separation process, you can enjoy peace of mind knowing that your cooling needs will be met reliably year-round. The integration of an oil separator not only enhances functionality but also fosters trust between users and their appliances—a win-win scenario! So when considering upgrades or installations for your cooling systems—remember: reliability starts with proper management!

Oil Separation Techniques in Refrigeration

When it comes to maintaining the efficiency of a refrigeration system, employing effective oil separation techniques is crucial. Each method has its unique approach to ensuring that the oil stays where it should—out of the evaporator refrigeration and other critical components like the compressor and condenser. By understanding these techniques, we can appreciate how they contribute to a more reliable air conditioning cycle.

Gravity-Based Separation Methods

Gravity-based separation methods leverage the natural principle of density differences between oil and refrigerant. In this setup, as the refrigerant flows through the system, it rises while heavier oil settles at the bottom, allowing for easy collection. This technique is often used in simpler refrigerator air conditioner designs but may not be sufficient alone for high-performance systems where oil management is critical.

These methods are relatively low-cost and simple to implement within an oil separator in refrigeration systems. However, they can be inefficient in scenarios with rapid refrigerant flow or when dealing with emulsified oils. Despite their limitations, gravity-based methods provide a foundational understanding of how effective oil separation can enhance the basic refrigeration cycle's performance.

Centrifugal Oil Separators

Centrifugal oil separators take things up a notch by utilizing centrifugal force to separate oil from refrigerants more efficiently than gravity-based methods can achieve alone. In these systems, a rotating element creates strong forces that push heavier particles—like oil—outward while allowing lighter gases to pass through unhindered. This technology significantly reduces risks associated with flooding in evaporator refrigeration units and ensures optimal operation of compressors.

The result? A more efficient refrigerator air conditioner that enhances overall system reliability and extends lifespan by reducing wear on crucial components like compressors and condensers. Given their effectiveness, centrifugal separators are increasingly common in modern commercial refrigeration setups where performance cannot be compromised.

Chemical Separation Processes

Chemical separation processes represent another innovative approach for managing oils within a refrigeration system effectively. These methods often involve introducing chemical agents that react with refrigerants to create separable compounds or facilitate easier removal of unwanted oils from vapor streams. While this technique may sound complex, it offers remarkable efficiency when integrated properly into an existing air conditioning cycle.

One significant advantage of chemical processes is their ability to handle emulsified oils that traditional mechanical means might struggle with effectively—ensuring that your compressor continues running smoothly without unwanted interruptions due to flooding or contamination issues in your evaporator refrigeration unit. However, careful consideration must be given during implementation since improper use could lead to adverse reactions affecting overall system performance.

Common Issues Without an Oil Separator

In a refrigeration system, the absence of an oil separator can lead to a cascade of problems that affect efficiency and performance. Without this critical component, oil can accumulate in places it shouldn't be, causing significant issues for the entire setup. Let's delve into some of the most pressing concerns that arise when an oil separator is missing from a refrigeration system.

Risk of Oil Flooding in the Evaporator

One of the primary dangers without an oil separator in refrigeration systems is the risk of oil flooding in the evaporator. When oil mixes with refrigerant, it can create a thick sludge that clogs up essential components within the evaporator refrigeration unit. This not only hampers heat exchange but also leads to inefficient cooling and potential system failure, ultimately disrupting your air conditioning cycle.

Increased Wear on the Compressor and Condenser

Without an effective oil separator, both the compressor and condenser face increased wear and tear due to excessive oil circulation. As more oil enters these components, they struggle to perform their functions efficiently; this leads to overheating and premature breakdowns. The added strain on your refrigeration compressor can significantly shorten its lifespan while increasing maintenance costs—definitely not what you want for your refrigerator air conditioner!

Reduced Performance of the Refrigerator Air Conditioner

Lastly, neglecting to include an oil separator in a refrigeration system results in reduced performance across all units involved in the basic refrigeration cycle. The compressor works harder under unfavorable conditions caused by excess oil, which translates into lower energy efficiency and higher utility bills for you as a consumer. Ultimately, this degradation affects not only cooling capacity but also overall comfort levels within your space—who wants that?

Choosing the Right Oil Separator

Selecting the appropriate oil separator in a refrigeration system is crucial for maintaining optimal performance and efficiency. With various options available, it's essential to consider specific factors that influence how well an oil separator integrates with your refrigerator air conditioner and overall air conditioning cycle. Making an informed choice can significantly impact the longevity and effectiveness of your refrigeration compressor, ensuring smooth operation throughout its lifespan.

Factors to Consider for Optimal Performance

When evaluating an oil separator in a refrigeration system, several key factors come into play. First, you'll want to assess the size and capacity of the oil separator; it should align with your refrigeration compressor's specifications to effectively manage oil return without causing flooding in the evaporator refrigeration unit. Additionally, consider the type of refrigerant used in your system, as some separators are optimized for particular refrigerants, enhancing their efficiency within the basic refrigeration cycle.

Another important factor is maintenance requirements; choosing a model that allows for easy access and cleaning can save time and money down the line. Furthermore, ensure compatibility with existing components such as compressors and condensers to avoid any operational hiccups that could compromise performance. Ultimately, understanding these aspects will guide you toward selecting an oil separator that not only fits but excels within your specific refrigeration setup.

Custom Solutions from ARCTIC

ARCTIC offers tailored solutions designed specifically to meet diverse needs when it comes to oil separators in refrigeration systems. Their expertise ensures that each product is engineered to optimize performance across various applications—from residential refrigerator air conditioners to larger commercial setups requiring robust air conditioning cycles. By collaborating with ARCTIC’s specialists, you can access custom designs that enhance both efficiency and reliability.

One of the standout features of ARCTIC's offerings is their commitment to innovation; they utilize advanced technology that maximizes oil separation while minimizing energy consumption—a win-win for both your wallet and environmental sustainability! Moreover, their products often come equipped with user-friendly interfaces that simplify monitoring and maintenance tasks associated with refrigerant management in any compressor or condenser setup. With ARCTIC’s custom solutions at hand, you’re guaranteed a seamless integration into your existing systems.

Importance of Professional Installation

While selecting the right oil separator is essential, professional installation cannot be overstated—it plays a pivotal role in ensuring optimal functionality within your refrigeration system. Proper installation guarantees that all components work harmoniously together—especially between critical elements like compressors, condensers, and evaporators—maximizing overall system performance during every phase of the air conditioning cycle.

Moreover, trained technicians possess invaluable experience dealing with potential pitfalls during installation; they can identify issues before they become costly problems down the line—like improper alignment or inadequate sealing—which might lead to inefficiencies or even equipment failure over time! Investing in professional installation not only saves you from future headaches but also enhances safety standards by adhering strictly to industry regulations regarding refrigerant handling.

In conclusion, choosing an appropriate oil separator requires careful consideration of various factors like size compatibility and maintenance ease while also recognizing the benefits offered by custom solutions from ARCTIC. Coupled with professional installation services ensuring seamless integration into your system’s basic refrigeration cycle, these steps will help safeguard against common pitfalls while optimizing efficiency across all components—ultimately leading you toward long-term savings!

Conclusion

In the realm of refrigeration, the oil separator plays a crucial role in maintaining system efficiency and reliability. By ensuring that the right amount of oil circulates through the refrigeration compressor, it prevents issues such as flooding and wear on components. Ultimately, incorporating an oil separator in refrigeration systems translates to smoother operation and prolonged equipment life.

Key Advantages of Using an Oil Separator

One of the standout advantages of utilizing an oil separator in refrigeration systems is improved efficiency across all components, especially in the refrigerator air conditioner. This device effectively separates oil from refrigerant, allowing for optimal lubrication of the compressor while minimizing contamination risks. The result is a seamless air conditioning cycle that operates at peak performance levels, reducing energy consumption and operational costs.

Long-term Cost Savings and Maintenance

Investing in an oil separator can lead to significant long-term cost savings for businesses and homeowners alike. By preventing issues like oil flooding in evaporator refrigeration units, these separators reduce maintenance needs and extend the lifespan of critical components like compressors and condensers. Over time, this means fewer repairs, lower energy bills, and a more reliable basic refrigeration cycle—who wouldn't want that?

Enhancing the Basic Refrigeration Cycle Efficiency

The integration of an oil separator enhances the overall efficiency of the basic refrigeration cycle by ensuring that each component functions optimally without interference from excess oil. This not only boosts performance but also contributes to a more reliable refrigerator air conditioner that can handle varying loads with ease. With improved efficiency comes enhanced comfort—after all, a well-functioning system keeps your space cool without breaking a sweat!