Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In a world where temperature control can make or break scientific progress, understanding cryogenic coolers is essential. These innovative devices are designed to operate at extremely low temperatures, often below -150 degrees Celsius, and play a pivotal role in various high-tech industries. But what exactly is a cryogenic cooler? This introduction will explore the fundamentals of cryogenic cooling, its significance in modern applications, and the fascinating technologies that make it possible.

Understanding Cryogenic Coolers

A cryogenic cooler is more than just a fancy freezer; it’s a sophisticated system that utilizes advanced principles of thermodynamics to achieve ultra-low temperatures. Unlike traditional coolers that rely on simple refrigeration cycles, cryogenic coolers employ specialized techniques such as Joule-Thomson expansion or Stirling cycle processes. By diving into the mechanics of what is a cryogenic cooler, one can appreciate how these systems maintain their frigid environments with precision and reliability.

The Importance of Cryogenic Cooling

Cryogenic cooling isn't just for keeping your ice cream frozen; it's crucial for numerous applications across various fields including medical technology, aerospace engineering, and quantum computing. The ability to reach such low temperatures allows for enhanced performance in superconductors and sensitive instruments used in research and diagnostics. Understanding why cryocoolers are so expensive often leads back to their importance—advanced materials and cutting-edge technology come at a premium but are necessary for pushing the boundaries of science.

Applications of Cryocoolers

From space exploration to medical imaging, the applications of cryocoolers are as diverse as they are critical. In the realm of healthcare, for instance, they're used in MRI machines where maintaining low temperatures enhances image quality by reducing noise from thermal vibrations. Additionally, industries like telecommunications rely on what is a cryogenic cooling system to ensure optimal performance under extreme conditions—highlighting just how integral these systems have become across multiple sectors.

What is a Cryogenic Cooler?

When you hear the term cryogenic cooler, you might picture something out of a sci-fi movie, but in reality, these devices are essential for various scientific and industrial applications. So, what is a cryogenic cooler? At its core, it's a specialized refrigeration system designed to achieve extremely low temperatures—often below -150 degrees Celsius. These coolers are crucial in fields like superconductivity research, medical imaging, and even space exploration.

Definition and Functionality

A cryogenic cooler is specifically engineered to cool materials to cryogenic temperatures, where unique physical properties emerge. Unlike regular cooling systems that might keep your beverages chilled, cryogenic coolers can reach temperatures that allow for the preservation of delicate materials or the enhancement of certain physical phenomena. The functionality of these systems often involves advanced thermodynamic cycles that enable efficient heat removal at very low temperatures.

How It Differs from Traditional Coolers

So how does a cryogenic cooler differ from traditional coolers? For starters, traditional coolers typically operate within the range of 0 to -20 degrees Celsius—think about your standard refrigerator or freezer. In contrast, cryogenic coolers push boundaries by achieving much lower temperatures necessary for specialized applications like liquefying gases or maintaining superconducting states in materials. This significant temperature difference requires entirely different technology and design principles.

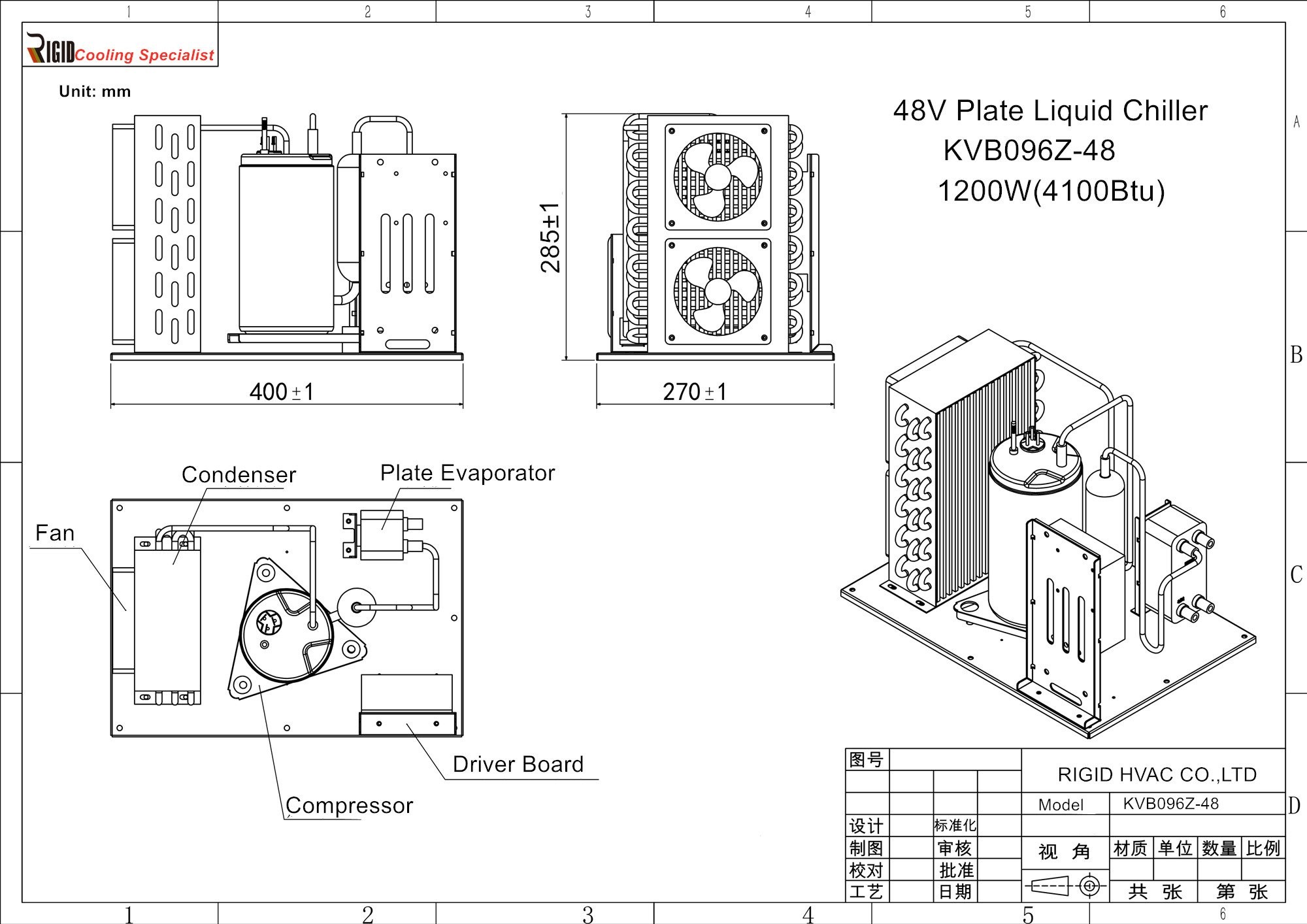

Key Components and Design

The key components of a cryogenic cooler include compressors, heat exchangers, and expansion devices—all meticulously designed to work together efficiently at ultra-low temperatures. The design often incorporates advanced materials capable of withstanding extreme conditions while minimizing thermal losses. Additionally, understanding what is a cryogenic cooling system entails recognizing that these components must be precisely engineered to ensure optimal performance and longevity under challenging operational stresses.

What is a Cryogenic Cooling System?

When we delve into the realm of cryogenic cooling systems, we uncover a fascinating interplay between physics and engineering. These systems are designed to achieve extremely low temperatures, often below -150°C (-238°F), which is essential for various scientific and industrial applications. Understanding the intricacies of what constitutes a cryogenic cooling system will help illuminate its critical role in modern technology.

The Science Behind Cryogenic Cooling

At its core, cryogenic cooling relies on principles of thermodynamics to lower temperatures effectively. When discussing What is a cryogenic cooler?, it's important to note that these coolers operate by removing heat from an enclosed space, utilizing gases or liquids that can reach extremely low boiling points. This process not only requires advanced materials but also precise control mechanisms to maintain stability at such low temperatures.

The science behind cryogenic cooling involves understanding how materials behave at these extreme temperatures; for instance, many metals become superconductors when cooled sufficiently. This phenomenon allows for applications in fields like particle physics and MRI technology. Thus, grasping the science behind these systems enhances our appreciation for their complexity and utility.

Components of a Cryogenic Cooling System

A typical cryogenic cooling system comprises several key components designed to work harmoniously together. First and foremost is the cryogenic cooler itself, which serves as the heart of the system by generating the necessary cold temperatures through various methods like Joule-Thomson or Stirling cycles. Additionally, insulation materials play an essential role in minimizing heat transfer from the environment to maintain efficiency.

Other critical components include compressors that circulate refrigerants and thermal shields that protect sensitive equipment from external heat sources. Each element must be engineered with precision because even minor discrepancies can lead to inefficiencies or failures in maintaining desired temperature levels. Understanding these components helps clarify why What is cryogenic cooling system? encompasses more than just chilling; it’s about creating an integrated environment where every part contributes to achieving ultra-low temperatures.

Types of Cryogenic Systems

Cryogenic systems come in various types tailored for specific applications and temperature requirements—each with unique features suited for different tasks. For instance, some systems utilize liquid nitrogen as a refrigerant due to its availability and cost-effectiveness, making it popular in laboratories and industrial settings alike. Others might employ helium-based systems for their superior performance at lower temperatures—ideal for research facilities needing precise conditions.

Another type includes closed-cycle coolers that recycle refrigerants within a sealed loop—a design choice that minimizes waste while maximizing efficiency over time. Each type has its own advantages depending on factors such as operational costs, required temperature range, and intended use case scenarios across industries like aerospace or healthcare—where understanding Why are cryocoolers so expensive? becomes crucial when evaluating budget constraints against performance needs.

Why Are Cryocoolers So Expensive?

When you dive into the world of cryogenic coolers, one question often arises: why are cryocoolers so expensive? The answer lies in a combination of factors, including manufacturing complexity, advanced technology requirements, and market demand. Understanding these elements can shed light on the high price tags associated with these sophisticated cooling systems.

Manufacturing Complexity

Creating a cryogenic cooler is no walk in the park; it’s akin to assembling a finely tuned Swiss watch. The precision required during manufacturing ensures that each component works seamlessly at extremely low temperatures, which adds layers of complexity to the production process. This meticulous attention to detail not only drives up labor costs but also demands specialized equipment and facilities tailored for producing what is essentially a high-performance machine.

Advanced Technology Requirements

What is a cryogenic cooling system without cutting-edge technology? Cryogenic coolers rely on advanced materials and innovative engineering techniques designed to withstand extreme conditions while maintaining efficiency. From superconducting magnets to sophisticated thermal insulation, the components used in these systems require extensive research and development, contributing significantly to their overall cost.

Market Demand and Innovation

The demand for efficient cooling solutions has surged across various industries—think aerospace, medical imaging, and even quantum computing—all of which utilize cryogenic refrigerators for their unique capabilities. As industries evolve and new technologies emerge, manufacturers are continually innovating to meet this growing demand while ensuring reliability and performance in their products. Consequently, this drive for innovation not only pushes prices higher but also creates an environment where consumers are willing to invest more for cutting-edge solutions.

What is a Cryogenic Refrigerator?

When we dive into the realm of cryogenic refrigerators, we're entering a fascinating world where temperatures plunge to incredibly low levels. Essentially, a cryogenic refrigerator is designed to achieve and maintain temperatures below -150 degrees Celsius (-238 degrees Fahrenheit), making it significantly cooler than your typical fridge. This capability allows for the preservation and manipulation of materials that require extreme cold, which leads us to explore how these specialized systems operate.

How Cryogenic Refrigerators Work

Cryogenic refrigerators utilize advanced cooling techniques that often involve the principles of gas expansion and compression—similar to what you might find in traditional refrigeration systems but taken to an extreme level. The process typically begins with a refrigerant gas that is compressed, causing it to heat up; this gas then passes through a heat exchanger where it cools down before expanding rapidly in an expansion chamber. This rapid expansion lowers the temperature dramatically, allowing the system to reach those cryogenic levels essential for various applications.

The efficiency of these cryogenic coolers hinges on their design elements, such as the choice of refrigerants and the configuration of components like compressors and heat exchangers. Unlike conventional refrigerators that rely on ambient temperature changes, cryogenic refrigerators are engineered for precision cooling—essentially creating an ultra-cold environment ideal for scientific research or industrial processes. With their unique functionality, they stand out as vital tools in numerous fields.

Common Uses in Various Industries

Cryogenic refrigerators find their niche across several industries due to their ability to maintain ultra-low temperatures efficiently. In medical applications, they are crucial for storing biological samples like blood plasma or stem cells at extremely low temperatures, ensuring long-term preservation without degradation. Additionally, in the field of electronics manufacturing, these systems play a pivotal role in producing superconductors and other components requiring precise thermal management.

The aerospace industry also benefits from cryogenic cooling systems; they are used extensively during rocket propulsion testing where liquid gases must be stored at sub-zero temperatures until needed for ignition. Furthermore, research institutions utilize these refrigerators for experiments involving quantum physics or materials science—fields that often require maintaining specific temperature conditions to observe phenomena accurately. As you can see, what is a cryogenic refrigerator? It’s not just about keeping things cold; it's about enabling innovation across various sectors.

Comparison with Standard Refrigerators

When comparing cryogenic refrigerators with standard household models, one quickly notices significant differences beyond just temperature ranges. Traditional refrigerators operate within a range suitable for food storage (typically between 0°C and 4°C), while cryogenic coolers plunge far deeper into sub-zero territory—often reaching minus hundreds of degrees Celsius! This drastic difference means that while standard fridges focus on preserving everyday items like milk and vegetables, cryogenic units cater specifically to high-tech applications requiring precise thermal control.

Moreover, while conventional refrigeration relies on simple vapor-compression cycles using common refrigerants like R-134a or R-410A, cryocoolers employ more complex mechanisms involving specialized gases such as helium or hydrogen under controlled conditions suited for low-temperature operations. The manufacturing complexity inherent in creating reliable and efficient cryogenic cooling systems explains why we often ask ourselves: why are cryocoolers so expensive? They aren’t just another appliance; they're sophisticated machines designed for specific scientific needs.

In summary, understanding what is a cryogenic refrigerator helps clarify its role within modern technology landscapes—whether it's preserving vital medical samples or enabling cutting-edge research breakthroughs.

Introduction to Arctic Active Cooling's FPSC

In the realm of cryogenic cooling systems, Arctic Active Cooling's FPSC (Field Programmable Stirling Cooler) stands out as a remarkable innovation. This advanced cryogenic cooler utilizes the Stirling cycle to achieve exceptionally low temperatures, making it a game changer in various applications. With its unique design and functionality, understanding what is a cryogenic cooler becomes essential for anyone looking to delve into the world of high-performance cooling solutions.

Overview of the FPSC

The FPSC is specifically designed for applications requiring reliable and efficient cryogenic cooling. Unlike traditional systems that may rely on bulky components, this cryogenic cooling system offers a compact and modular design that can be easily integrated into existing setups. By harnessing the principles of thermodynamics, the FPSC delivers impressive cooling performance while maintaining energy efficiency.

Advantages of the Stirling Cooler

One standout advantage of the Stirling cooler used in Arctic's FPSC is its ability to provide precise temperature control across a wide range of applications. This feature is particularly valuable in scientific research and medical imaging, where consistent temperatures are crucial for optimal performance. Additionally, due to its minimal moving parts compared to other types of cryocoolers, maintenance costs are significantly reduced—addressing concerns about why are cryocoolers so expensive.

Performance Metrics and Applications

When evaluating performance metrics for Arctic’s FPSC, one must consider factors such as cooling capacity, noise levels, and reliability under various operating conditions. The versatility of this cryogenic refrigerator extends beyond laboratory use; it finds applications in aerospace engineering, semiconductor manufacturing, and even space exploration missions. Understanding what is a cryogenic refrigerator becomes relevant here as well since these coolers ensure that sensitive equipment remains operational at extremely low temperatures.

Conclusion

In wrapping up our exploration of cryogenic coolers, it’s clear that these remarkable devices play a pivotal role in various high-tech applications. As we’ve seen, understanding what is a cryogenic cooler is essential for appreciating its significance in fields ranging from medicine to space exploration. The future of cryogenic cooling systems looks bright, with advancements promising even more efficient and versatile solutions.

The Future of Cryogenic Cooling Systems

The future of cryogenic cooling systems is poised for exciting developments driven by innovation and demand. With ongoing research into materials and designs, we can expect to see enhancements that will make what is a cryogenic cooling system more accessible and efficient than ever before. Furthermore, as industries grow increasingly reliant on advanced technologies, the need for effective cryocoolers will only continue to rise.

Key Takeaways on Cryogenic Coolers

When considering why are cryocoolers so expensive, it becomes evident that their complexity and the cutting-edge technology involved contribute significantly to their price tag. However, understanding what is a cryogenic refrigerator versus other cooling systems highlights the unique advantages offered by these specialized machines. Ultimately, whether you’re looking into industrial applications or scientific research, grasping the nuances of these devices can guide you in making informed decisions.

Selecting the Right Cryogenic Solution

Selecting the right cryogenic solution requires careful consideration of your specific needs and applications. It’s essential to evaluate factors such as performance metrics and compatibility with existing systems when pondering what is a cryogenic cooler suitable for your project. By understanding both what is a cryogenic cooling system and its various types, you’ll be better equipped to make choices that align with your goals while maximizing efficiency.