Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the world of refrigeration systems, every component plays a vital role in ensuring efficiency and reliability. Among these components, solenoid valves stand out as crucial players in managing refrigerant flow and maintaining optimal performance. Specifically, the liquid line solenoid valve is an essential part of this system, acting as a gatekeeper that regulates the flow of refrigerant and prevents potential issues.

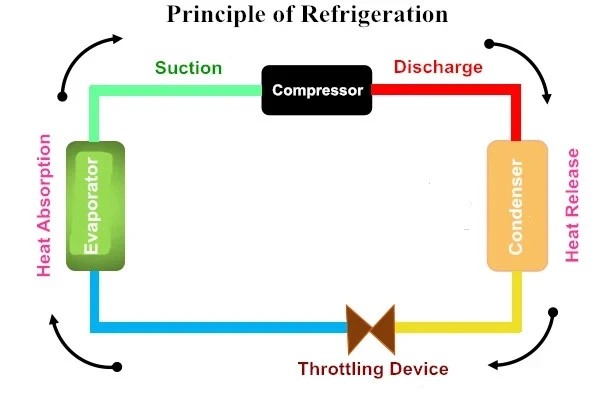

Understanding Refrigeration Systems

Refrigeration systems operate on the principle of heat transfer, using refrigerants to absorb heat from one area and release it in another. The efficiency of these systems hinges on various components working harmoniously together, including compressors, condensers, evaporators, and yes—solenoid valves for refrigeration systems. Understanding how these elements interact helps us appreciate the importance of each part in maintaining a balanced system.

Importance of Solenoid Valves

Solenoid valves are electrically operated devices that control the flow of fluids within HVAC-R systems. They are pivotal for automating processes like starting or stopping refrigerant flow based on system demands. Without efficient solenoid valves for HVAC-R applications, systems could suffer from inefficiencies or even failures that lead to costly repairs.

The Role of the Liquid Line Solenoid

So what is a liquid line solenoid valve for? This specific type of valve controls refrigerant flow in the liquid line between the condenser and evaporator. Its primary purpose is to manage refrigerant delivery while preventing backflow issues that can compromise system performance; understanding this role is key to recognizing when maintenance or replacement might be necessary.

What is a Liquid Line Solenoid Valve?

A liquid line solenoid valve is a crucial component in refrigeration systems that regulates the flow of refrigerant through the liquid line. These valves are designed to open and close based on electrical signals, effectively controlling the refrigerant's movement and ensuring optimal system performance. Understanding what a liquid line solenoid valve does is essential for anyone involved in HVAC-R, as it plays a pivotal role in maintaining system efficiency.

Basic Definition and Functionality

So, what is a liquid line solenoid valve for? Simply put, it functions as an electrically operated valve that controls the flow of refrigerant in the liquid line of refrigeration systems. When energized, the solenoid coil creates a magnetic field that pulls up or pushes down a plunger, opening or closing the valve accordingly. This action allows for precise management of refrigerant flow, which is vital for maintaining proper cooling and heating cycles.

How It Works in Refrigeration Systems

In refrigeration systems, the liquid line solenoid valve works by responding to changes in pressure and temperature within the system. When the compressor operates, it builds pressure that can be sensed by various components, including this valve. If conditions are right—like when cooling is needed—the solenoid opens to allow refrigerant to flow into evaporators; if not needed, it closes to prevent unnecessary circulation.

Components of a Liquid Line Solenoid Valve

A typical liquid line solenoid valve consists of several key components: an electromagnet (the coil), a plunger (or armature), and housing that contains these parts along with inlet and outlet ports for refrigerant flow. The electromagnet generates magnetic force when electricity passes through it; this force moves the plunger to open or close the passageway for refrigerant. Additionally, seals are included to prevent leaks and ensure reliable operation under varying pressures common in refrigeration systems.

Purpose of the Liquid Line Service Valve

The liquid line service valve plays a crucial role in refrigeration systems, primarily by managing the flow of refrigerant. Understanding what is the purpose of the liquid line service valve is essential for anyone working with HVAC-R systems. This valve ensures that refrigerant moves efficiently through the system, enhancing overall performance and reliability.

Managing Refrigerant Flow

At its core, the liquid line solenoid valve is designed to manage refrigerant flow effectively. By controlling when and how much refrigerant enters various parts of the system, it helps maintain optimal pressure levels and temperature regulation. This precise management prevents issues like overcharging or undercharging, which can lead to inefficiencies and costly repairs.

Preventing Backflow Issues

One of the key functions of a liquid line service valve is preventing backflow issues that could compromise system integrity. Without proper backflow prevention, refrigerants can flow in unintended directions, potentially causing damage or failure in components downstream. In essence, this valve acts as a gatekeeper, ensuring that refrigerants only travel where they are supposed to go.

Enhancing System Efficiency

Enhancing system efficiency is another significant purpose served by the liquid line solenoid valve. When these valves operate correctly, they help minimize energy consumption by ensuring that only necessary amounts of refrigerant circulate through the system at any given time. This not only saves energy but also extends the lifespan of your HVAC-R equipment—talk about a win-win situation!

Indicators of a Bad Liquid Line Solenoid Valve

Recognizing when your liquid line solenoid valve is on the fritz can save you from bigger headaches down the line. This vital component plays a significant role in managing refrigerant flow, so any malfunction can lead to inefficiencies or system failures. If you're wondering, How do I know if my liquid line solenoid valve is bad?, keep an eye out for some telltale signs.

Common Symptoms to Watch For

There are several indicators that your liquid line solenoid valve might be misbehaving. One of the most common symptoms is inconsistent cooling; if your refrigeration system can't maintain its temperature, it could be due to a faulty solenoid valve. Additionally, unusual noises—like hissing or clicking sounds—often signal that something's not right with this critical component.

Another red flag is refrigerant leaks around the valve area, which can compromise system efficiency and safety. If you notice frost forming on the valve itself, it's another sign that your liquid line solenoid valve may need attention. These symptoms should prompt you to ask: What is the purpose of the liquid line service valve? It’s essential for maintaining proper refrigerant flow and preventing backflow issues.

Troubleshooting Tips

When faced with potential issues related to a liquid line solenoid valve, start by conducting a visual inspection of the entire refrigeration system. Check for any obvious signs of wear or damage around the solenoid and associated fittings; sometimes, loose connections can cause problems that mimic more severe failures. If everything looks intact but problems persist, consider testing the electrical connections leading to the solenoid.

You might also want to check whether power is reaching the solenoid when it should be open; using a multimeter can help with this task. If you're still scratching your head about what’s wrong after these steps, consult an HVAC professional who understands solenoid valves for HVAC-R systems—they have specialized knowledge about these components and their quirks.

When to Replace or Repair

Deciding whether to replace or repair your liquid line solenoid valve depends on various factors such as age and severity of damage. If you've identified consistent issues despite troubleshooting efforts—or if you find signs of corrosion—it’s likely time for a replacement rather than another repair attempt. Remember that even minor malfunctions in this critical component can lead to inefficiencies in refrigeration systems over time.

On the other hand, if you've only noticed intermittent problems and they appear fixable through simple adjustments or cleaning, repairing might just do the trick! The key takeaway here is not to ignore those warning signs; timely action can prevent costly breakdowns in your HVAC-R system later down the road.

How to Manually Open a Liquid Line Solenoid Valve?

When faced with the need to manually open a liquid line solenoid valve, understanding the process is crucial for maintaining your refrigeration system's efficiency. A liquid line solenoid valve plays an essential role in controlling refrigerant flow, and knowing how to operate it manually can be a lifesaver during troubleshooting or maintenance. Let’s dive into the steps you need to follow.

Step-by-Step Guide

1. **Power Down the System**: Before you start, ensure that your refrigeration system is powered down completely. This step is vital for safety and prevents any accidental activation of the liquid line solenoid valve while you're working on it.

2. **Locate the Liquid Line Solenoid Valve**: Identify where the liquid line solenoid valve is situated within your HVAC-R system. Typically, it's located near the compressor or at the entry point of the evaporator coil.

3. **Manually Open the Valve**: Look for a manual override feature on your liquid line solenoid valve; this could be a lever or knob designed for manual operation. Turn or pull this mechanism gently until you feel resistance, indicating that you've opened it fully.

4. **Check for Proper Operation**: Once opened, observe if refrigerant flow resumes as expected through the system components connected to that valve. If everything seems normal, you can proceed with any necessary repairs or checks.

5. **Reassemble and Power Up**: After completing your tasks, ensure all components are securely reassembled before powering up your refrigeration system again.

Tools Required for the Process

To successfully open a liquid line solenoid valve manually, you'll need some basic tools at hand:

1) **Wrench Set**: Depending on your specific model of liquid line solenoid valve, you may require various sizes of wrenches to loosen fittings.

2) **Screwdriver**: A flathead or Phillips screwdriver will help in removing any covers or securing screws around the solenoid assembly.

3) **Safety Goggles and Gloves**: Always wear protective gear when working with HVAC-R systems to safeguard against any potential hazards.

These tools will aid in ensuring that you can complete this task efficiently without complications.

Safety Precautions to Consider

Safety should always be your top priority when dealing with HVAC-R systems and their components like a liquid line solenoid valve:

1. **Disconnect Power Supply**: Always disconnect power before starting work on any electrical components to avoid shocks or injuries related to live wires.

2. **Wear Protective Gear**: Equip yourself with safety goggles and gloves as refrigerants can be hazardous if they leak during handling.

3. **Ventilation is Key**: Ensure that you're working in a well-ventilated area when opening up any part of your refrigeration system; this helps minimize exposure to potentially harmful gases released by refrigerants.

By following these steps and precautions carefully, you'll not only know how to manually open a liquid line solenoid valve but also do so safely while maintaining optimal functionality in your HVAC-R systems!

Overview of Solenoid Valves for HVAC-R

When it comes to HVAC-R systems, solenoid valves play a pivotal role in regulating the flow of refrigerants and ensuring optimal performance. Among these, the liquid line solenoid valve stands out as a crucial component that manages the flow of refrigerant in a refrigeration system. Understanding the various types and applications of solenoid valves is essential for anyone looking to enhance their HVAC-R knowledge.

Types and Applications

Solenoid valves for HVAC-R come in several varieties, each designed for specific applications within refrigeration systems. The most common types include normally closed, normally open, and pilot-operated solenoid valves. Each type serves distinct functions; for instance, a liquid line solenoid valve typically operates in a normally closed position, allowing refrigerant to flow only when energized.

Applications vary widely—from controlling refrigerant flow in air conditioning units to managing pressure levels in commercial refrigeration systems. The versatility of these valves makes them integral to both residential and industrial setups. Understanding what is a liquid line solenoid valve for? helps technicians select the right type based on system requirements.

Key Differences in Design

The design differences among solenoid valves can significantly affect their functionality and efficiency within HVAC-R systems. For instance, some liquid line solenoid valves are designed with specific materials that can withstand high pressures or corrosive environments. Additionally, variations exist in terms of size, voltage ratings, and actuation methods—features that must be carefully considered during installation or replacement.

One key distinction lies between direct-acting and pilot-operated designs; while direct-acting valves respond immediately to electrical signals, pilot-operated versions use pressure differentials for operation. Recognizing these differences can help technicians troubleshoot issues effectively—such as knowing how do I know if my liquid line solenoid valve is bad?

Benefits to Refrigeration Systems

Investing in quality solenoid valves for refrigeration systems yields numerous benefits that enhance overall efficiency and reliability. For starters, these components help maintain precise control over refrigerant flow, which is vital for system performance—especially when considering what is the purpose of the liquid line service valve? Efficient refrigerant management not only improves cooling capacity but also reduces energy consumption.

Moreover, well-functioning solenoid valves minimize risks associated with backflow issues that could lead to system failures or costly repairs down the road. They also contribute significantly towards extending equipment lifespan by reducing wear caused by improper fluid dynamics within the system. Ultimately, understanding how to manually open a liquid line solenoid valve can empower technicians during maintenance tasks or emergency situations.

Conclusion

In summary, understanding the role of the liquid line solenoid valve is crucial for maintaining efficient refrigeration systems. These valves not only manage refrigerant flow but also prevent backflow issues that can lead to system inefficiencies. Knowing how to identify a malfunctioning valve and how to manually open a liquid line solenoid valve can save both time and money in HVAC-R operations.

Key Takeaways About Liquid Line Solenoid Valves

So, what is a liquid line solenoid valve for? Primarily, it serves as a gatekeeper for refrigerant flow within the system, ensuring that only the right amount reaches critical components when needed. If you ever find yourself asking, How do I know if my liquid line solenoid valve is bad? remember that common symptoms include inconsistent cooling and unusual noises—red flags that should prompt further investigation.

Importance in HVAC-R Systems

The purpose of the liquid line service valve cannot be overstated; it plays an essential role in enhancing system efficiency and reliability in HVAC-R systems. With proper functionality, these valves help maintain optimal refrigerant levels while preventing potential backflow issues that could compromise performance. In essence, without effective solenoid valves for refrigeration systems, your cooling units might suffer from reduced efficiency or even complete failure.

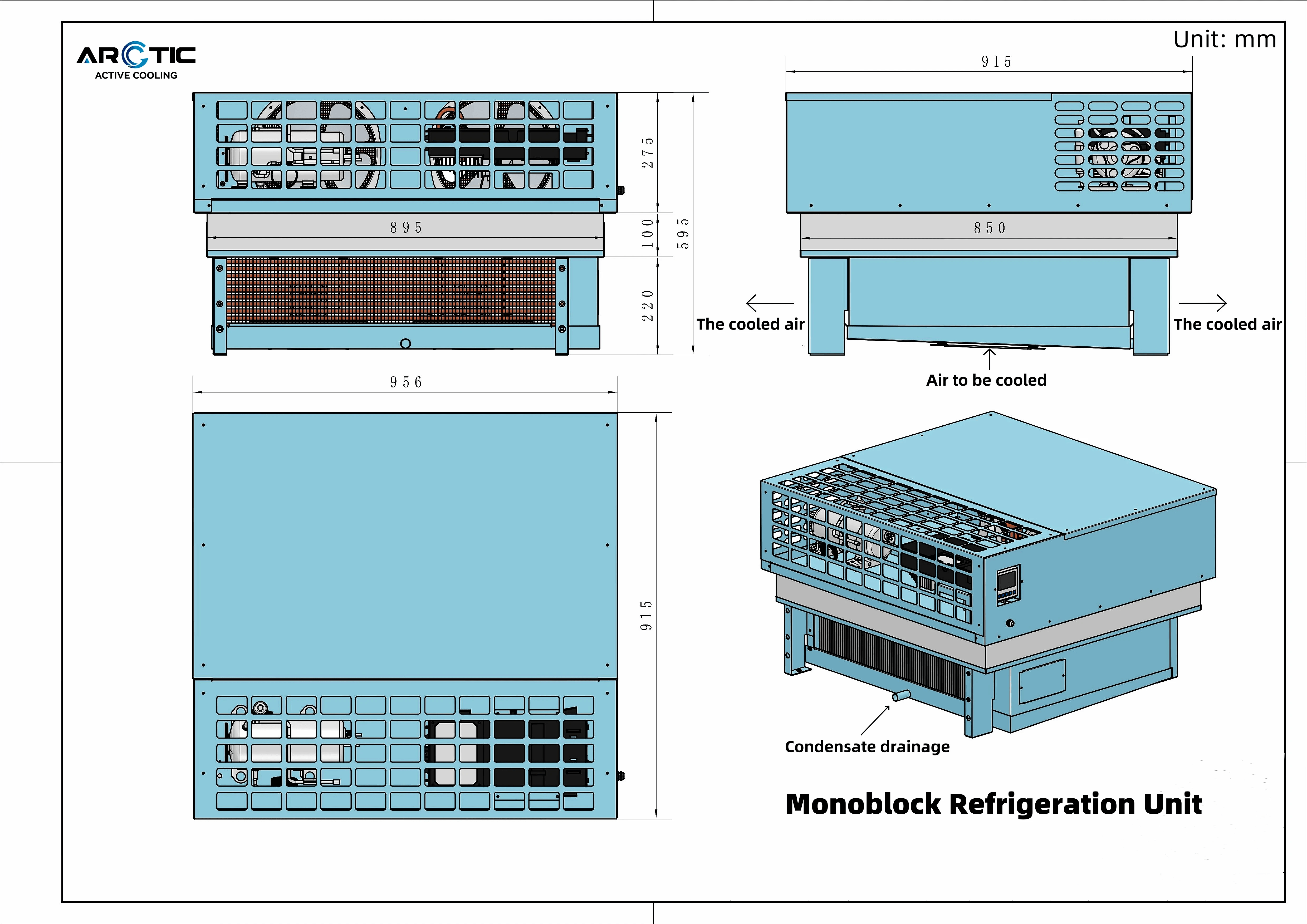

Custom Solutions Offered by ARCTIC

At ARCTIC, we understand that one size does not fit all when it comes to HVAC-R solutions; that's why we offer custom solutions tailored specifically to your needs. Our expertise extends to providing high-quality liquid line solenoid valves designed for various applications within refrigeration systems. Whether you're looking for standard models or specialized options, our team is here to help you optimize your system's performance with reliable products.