Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the world of cooling technology, the spotlight shines brightly on laser liquid chill systems, which have become indispensable in various industrial applications. These systems are designed to maintain optimal temperatures for high-performance equipment, ensuring efficiency and longevity. At the heart of many of these advanced cooling solutions lies the Copeland scroll compressor, a key player that enhances performance and reliability.

Understanding Laser Liquid Chill Systems

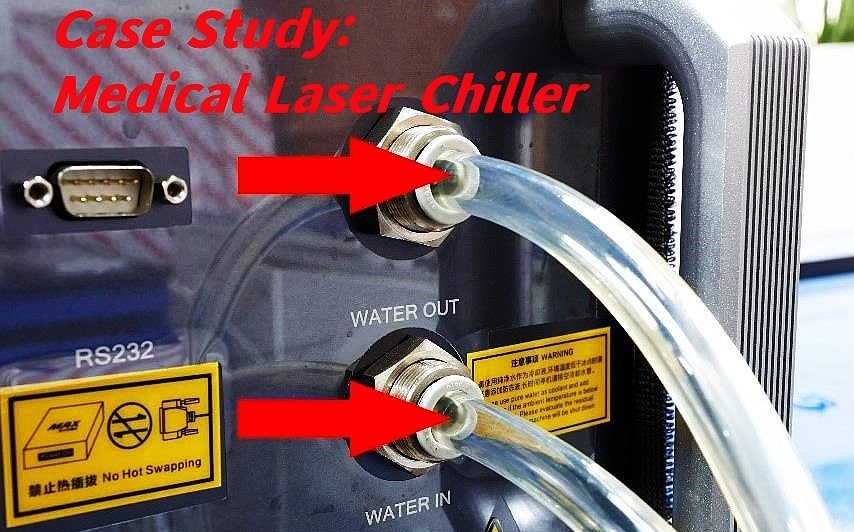

Laser liquid chillers are specialized cooling units that manage heat generated by lasers and other high-energy devices. Unlike traditional HVAC systems or central air compressors that cool entire spaces, laser chillers focus on precise temperature control to protect sensitive machinery from overheating. This targeted cooling approach is essential in industries such as manufacturing, medical technology, and research laboratories where precision is paramount.

The Role of the Copeland Scroll Compressor

The Copeland scroll compressor serves as a vital component within many laser liquid chillers, delivering consistent and efficient performance. Its unique design allows for smooth operation with fewer moving parts compared to conventional HVAC compressors, reducing wear and tear over time. This reliability is crucial for maintaining the delicate balance of temperature control required in laser applications.

Benefits of Using a Copeland Compressor

Opting for a Copeland compressor brings numerous advantages to cooling systems beyond just reliability; it also enhances energy efficiency significantly. The advanced technology behind the scroll compressor minimizes energy consumption while maximizing output—an essential factor when considering long-term operational costs. Additionally, users can expect lower maintenance needs and improved overall system performance when integrating a Copeland scroll compressor into their setup.

What is a Laser Liquid Chiller?

Laser liquid chillers are specialized cooling systems designed to maintain optimal temperatures for laser equipment and other sensitive technologies. These systems utilize advanced cooling mechanisms, often integrating a Copeland scroll compressor, to ensure efficient heat removal and stable operating conditions. Unlike traditional HVAC compressors or central air compressors, laser chillers focus on precise temperature control, making them ideal for high-performance applications.

Overview of Cooling Applications

Cooling applications for laser liquid chillers span various industries including manufacturing, medical technology, and telecommunications. In these settings, maintaining consistent temperatures is crucial to prevent overheating of equipment like lasers and high-powered electronics. By utilizing a compressor Copeland within the system, users can achieve superior cooling performance compared to standard AC air compressors.

Importance in Industrial Settings

In industrial environments where precision is key, the importance of laser liquid chillers cannot be overstated. They play a vital role in enhancing productivity by ensuring that machinery operates within safe temperature ranges. The integration of a Copeland scroll compressor further boosts reliability and efficiency—qualities that are indispensable in sectors relying on continuous operation without downtime.

Key Components of a Laser Chiller

Key components of a laser chiller include the evaporator, condenser, expansion valve, and the heart of the system—the compressor for air conditioning unit or specifically a Copeland scroll compressor. Each part works in harmony to transport heat away from sensitive equipment effectively while minimizing energy consumption. With its compact design and efficient operation, the scroll compressor is particularly favored for its ability to provide consistent cooling without sacrificing performance.

The Technology Behind the Copeland Scroll Compressor

How Scroll Compressors Work

At the heart of every Copeland scroll compressor is a unique mechanism that sets it apart from conventional AC air compressors. The compressor operates by trapping refrigerant between two spirals—one fixed and one orbiting—effectively compressing the gas as it moves through the system. This continuous compression process results in smoother operation with minimal vibration, significantly improving performance and extending the lifespan of the unit compared to a standard HVAC compressor.

Advantages Over Traditional HVAC Compressors

One of the most notable advantages of using a Copeland compressor is its energy efficiency. Scroll compressors generally consume less power than their piston-driven counterparts, translating into lower energy bills for users over time. Additionally, because they have fewer moving parts, these compressors experience less friction and heat generation, further enhancing their performance compared to traditional central air compressors.

Another advantage lies in their quiet operation; many users appreciate how much quieter a scroll compressor runs compared to typical HVAC compressors that can be quite noisy during operation. This makes them particularly suitable for settings where noise reduction is essential, such as offices or residential areas. Moreover, with their ability to maintain consistent pressure levels, Copeland scroll compressors provide reliable cooling without sudden fluctuations that can stress other systems.

Why Choose a Copeland Compressor?

Choosing a Copeland scroll compressor means investing in cutting-edge technology designed for optimal performance and longevity. Known for their robust construction and low maintenance requirements, these compressors are built to withstand demanding conditions while delivering exceptional cooling capabilities for both industrial applications and everyday use in residential settings.

Moreover, when you opt for a compressor copeland unit, you're not just getting any old piece of equipment; you're choosing an industry leader renowned for innovation and reliability in air conditioning technology. From energy savings to quiet operation and extended service life, selecting a Copeland compressor is undoubtedly a smart choice for anyone looking to enhance their cooling system's efficiency.

Comparing Central Air and Laser Liquid Chillers

Differences in Functionality

Central air compressors operate primarily by circulating cooled air through ducts to maintain comfortable indoor temperatures in residential or commercial spaces. In contrast, laser liquid chillers utilize a closed-loop system that circulates chilled liquid directly to specific equipment, such as lasers or industrial machinery. The Copeland scroll compressor plays a pivotal role in the efficiency of laser chillers by compressing refrigerant gas into a high-pressure state before it enters the evaporator, ensuring optimal performance.

Laser chillers are designed for precision cooling applications where temperature control is critical, while central air systems focus on maintaining overall room comfort. The compressor for an air conditioning unit typically handles larger volumes of air over extended periods but may struggle with the rapid response times required in specialized settings like laser operations. Thus, understanding these functional distinctions can guide users toward selecting the appropriate system based on their specific cooling requirements.

When to Use Each Type

Choosing between a central air compressor and a laser liquid chiller depends largely on your application needs. If you're looking to cool an entire building or space efficiently, especially during hot summer months, then a traditional HVAC compressor might be your best bet. However, if you require precise temperature control for sensitive equipment—like lasers used in manufacturing or medical procedures—a laser liquid chiller equipped with a Copeland scroll compressor is essential.

In scenarios where energy efficiency and consistent performance are paramount—such as data centers or laboratories—laser chillers excel due to their ability to maintain tight temperature tolerances without wasting energy. Conversely, central air systems shine in residential settings where comfort is key but may not provide the same level of precision required for industrial applications. Ultimately, knowing when to deploy each type can save time and resources while enhancing operational effectiveness.

Performance Metrics

Evaluating performance metrics is vital when comparing central air compressors with laser liquid chillers; both have unique benchmarks that reflect their capabilities under different conditions. For instance, energy efficiency ratings (EER) are crucial for HVAC compressors as they indicate how effectively they convert electrical power into cooled air over time—a key consideration for homeowners seeking lower utility bills. In contrast, laser chillers often emphasize cooling capacity measured in tons and temperature stability metrics since they must deliver consistent output under varying loads.

The Copeland scroll compressor contributes significantly to improved performance metrics within laser chillers by minimizing energy consumption while maximizing output efficiency compared to traditional AC units that rely on reciprocating designs. Additionally, factors like noise levels and maintenance requirements also play roles; scroll compressors tend to operate more quietly than standard HVAC compressors due to fewer moving parts—making them ideal for environments requiring minimal disruption. By examining these performance indicators closely, users can make well-informed decisions tailored specifically to their cooling needs.

The Importance of Efficiency in Cooling Systems

Energy Efficiency Ratings Explained

Energy efficiency ratings are crucial metrics that help consumers evaluate the performance of their HVAC compressor options. These ratings often come in the form of SEER (Seasonal Energy Efficiency Ratio) for air conditioning units and EER (Energy Efficiency Ratio) for more specific applications like laser chillers. A higher rating means better efficiency; thus, investing in equipment with superior energy efficiency can lead to significant long-term savings.

When looking at various options, such as a traditional central air compressor versus a modern scroll compressor like the Copeland compressor, it's essential to compare these ratings closely. The difference between an average HVAC compressor and one with high energy efficiency can be substantial over time—both in terms of performance and cost-effectiveness. Ultimately, making choices based on these metrics will enhance your overall cooling experience.

How the Copeland Scroll Compressor Improves Efficiency

The Copeland scroll compressor stands out as an efficient powerhouse among HVAC compressors due to its unique design and operation principles. Unlike traditional compressors that rely on pistons and complex moving parts, the scroll design features two interleaved spirals that compress refrigerant smoothly and continuously. This results in less mechanical wear and tear while maximizing energy conversion—essentially making it one of the most efficient compressors for air conditioning units available today.

Moreover, this enhanced design minimizes vibration and noise levels compared to standard central air compressors or other HVAC compressors on the market. This not only contributes to a quieter environment but also leads to lower maintenance costs over time since fewer moving parts mean less potential for breakdowns or repairs. Therefore, choosing a Copeland scroll compressor translates into improved reliability alongside its impressive efficiency.

Long-Term Cost Savings

Investing in an efficient cooling system equipped with a Copeland scroll compressor pays off handsomely over time through reduced operational costs. With lower energy consumption thanks to high-efficiency ratings and innovative technology, users can expect noticeable savings on their monthly utility bills compared to using older models or less efficient central air compressors.

Additionally, because these systems require less frequent maintenance due to their robust design—a hallmark of any quality compressor for an air conditioning unit—owners save money not just on electricity but also on upkeep expenses over years of usage. As businesses increasingly prioritize sustainability alongside profitability, opting for advanced solutions like the Copeland scroll compressor becomes not just smart but essential.

Custom Solutions from ARCTIC

When it comes to cooling systems, one size definitely does not fit all. At ARCTIC, we understand that each application has unique requirements, and our custom solutions are designed to meet those specific needs. Whether you're looking for a robust compressor for air conditioning units or an efficient cooling system for laser applications, we tailor our offerings to ensure optimal performance.

Tailoring Chill Solutions to Your Needs

Our approach begins with understanding your specific cooling requirements, allowing us to recommend the most suitable options. By utilizing the versatile Copeland scroll compressor, we can create systems that deliver exceptional efficiency while fitting seamlessly into your operational framework. This tailored strategy ensures that you get the most out of your investment in a compressor copeland or any other HVAC compressor.

Every industry has its own set of challenges when it comes to temperature control. From laser cutting operations needing precise temperature management to commercial spaces requiring reliable central air compressors, ARCTIC accommodates diverse applications with customized solutions. Our team collaborates closely with clients throughout the process, ensuring every detail aligns with your operational goals.

The ARCTIC Design Process Explained

Designing a custom cooling solution at ARCTIC is a meticulous process that combines innovation and practicality. We start by gathering detailed information about your existing systems and performance expectations before moving on to conceptual design phases where we incorporate advanced technologies like the Copeland scroll compressor. This ensures we're not just creating another HVAC compressor; we're engineering a high-performance solution tailored specifically for you.

Once we have a solid design in place, our engineers utilize state-of-the-art modeling software to simulate how our proposed system will perform under various conditions. This step allows us to optimize energy efficiency and ensure compatibility with existing infrastructure—whether it's an AC air compressor setup or something more specialized like a laser liquid chiller. After finalizing the designs, we move into production while maintaining strict quality control standards throughout manufacturing.

Testing and Reliability in Cooling Systems

At ARCTIC, reliability is non-negotiable; that's why rigorous testing is integral to our design process. Each system undergoes comprehensive testing scenarios mimicking real-world conditions before it ever reaches your facility—ensuring everything from the Copeland scroll compressor down to individual components meets stringent performance benchmarks. You can rest easy knowing that your custom solution has been thoroughly vetted for durability and efficiency.

We also focus on long-term reliability by incorporating features that enhance maintenance ease and reduce downtime—critical factors in industrial environments where every minute counts! Our commitment extends beyond just delivering a product; we aim for lasting partnerships by providing ongoing support after installation so you can maximize the benefits of your new system efficiently over time.

In summary, whether you're investing in a new central air compressor or upgrading an existing setup with advanced technologies like the Copeland scroll compressor, ARCTIC is here every step of the way with tailored solutions designed just for you!

Conclusion

In summary, laser liquid chillers represent a crucial technology for efficient cooling in various industrial applications. The Copeland scroll compressor stands out as a reliable choice, offering distinct advantages over traditional HVAC compressors. By understanding both the functionality of laser chillers and the benefits of using a Copeland compressor, businesses can make informed decisions that enhance their operational efficiency.

Key Takeaways on Laser Liquid Chillers

Laser liquid chillers are essential for maintaining optimal temperatures in high-precision environments, such as manufacturing and medical applications. Their design incorporates advanced components that ensure consistent performance and reliability. When paired with a Copeland scroll compressor, these systems achieve superior energy efficiency compared to standard central air compressors or HVAC compressors.

The Future of Copeland Scroll Compressors

The future looks bright for the Copeland scroll compressor as advancements in technology continue to enhance its performance and efficiency. With increasing demand for energy-efficient solutions in cooling systems, this compressor type is poised to lead the market. As industries strive to reduce their carbon footprint, the versatility and reliability of the compressor for air conditioning units will play a pivotal role in shaping sustainable practices.

Making Informed Choices in Cooling Technology

When selecting a cooling system, it's vital to consider both immediate needs and long-term operational costs. Opting for a high-quality solution like the Copeland scroll compressor can yield significant cost savings over time due to its energy-efficient design. By weighing all options—including central air compressors versus specialized systems—businesses can invest wisely in technologies that promote efficiency and reliability.