Introduction

In the realm of advanced manufacturing and precision engineering, maintaining optimal temperatures is essential for performance and longevity. This is where laser cooling technology comes into play, offering innovative solutions like the CO2 laser chiller and various types of water chillers designed specifically for lasers. By understanding how these systems work, we can appreciate their significant role in enhancing efficiency across multiple applications.

Understanding Laser Cooling Technology

Laser coolers are specialized devices that utilize advanced cooling methods to manage heat generated during laser operations. These systems often incorporate a laser water chiller or a CO2 laser water chiller that helps maintain consistent temperatures, ensuring that the machinery operates smoothly without overheating. The integration of these technologies is crucial for industries relying on high-performance laser cutting and engraving processes.

Importance of Efficient Cooling Solutions

Efficient cooling solutions are vital not only for the performance of lasers but also for extending their lifespan and reducing maintenance costs. A well-functioning water chiller for a laser cutter can significantly improve operational efficiency by preventing thermal damage to components such as CPUs or other sensitive electronics involved in the process. As industries evolve, the demand for reliable cooling systems like CPU chillers continues to grow, emphasizing the need for innovation in this field.

Overview of Laser Coolers and Applications

Laser coolers have found applications in various sectors, from industrial manufacturing to medical research, providing customized solutions tailored to specific needs. The versatility of products like Arctic Active Cooling's Mini Water Chiller showcases how compact designs can deliver high-efficiency performance while integrating seamlessly with existing systems. With advancements in technology paving the way forward, understanding these tools will be essential as we explore their diverse uses and benefits further.

What is a Laser Cooler?

Laser coolers are specialized cooling systems designed to maintain optimal temperatures for laser equipment, ensuring efficient operation and longevity. These devices are crucial in various applications, particularly where CO2 lasers are involved, as they help dissipate heat generated during the laser cutting or engraving processes. By utilizing advanced technology, laser water chillers provide consistent cooling performance that is essential for high-quality results.

Definition and Functionality

A laser cooler is essentially a refrigeration unit that regulates the temperature of laser systems to prevent overheating and ensure peak performance. Its primary functionality lies in removing excess heat from components like the CO2 laser tube, mirrors, and lenses, which can degrade performance if not adequately cooled. In doing so, a water chiller for lasers enhances efficiency and extends the lifespan of expensive equipment.

The operation of a CO2 laser chiller involves circulating chilled water through the system—absorbing heat from critical components before returning to the cooler for re-chilling. This continuous cycle ensures that temperatures remain stable during operation, which is vital in industries such as manufacturing and medical research. Ultimately, these systems play an indispensable role in maintaining precision and reliability in various applications.

Key Components and Design

The design of a laser cooler typically includes several key components: a compressor, condenser, evaporator, expansion valve, and water reservoir. The compressor compresses refrigerant gas into a high-pressure state; then it moves to the condenser where it releases heat and transforms into liquid form. This liquid refrigerant then passes through an expansion valve before entering the evaporator where it absorbs heat from the water circulating through the system.

In addition to these core components, many modern CO2 laser water chillers incorporate advanced features like digital controls for precise temperature management and monitoring systems that provide real-time feedback on performance metrics. The integration of these technologies not only enhances user experience but also improves energy efficiency—making them increasingly popular among users who demand high-performance cooling solutions for their lasers.

Moreover, compact designs have become prevalent among manufacturers like Arctic Active Cooling who aim to optimize space without compromising on functionality or performance. Their Mini Water Chiller boasts an efficient refrigeration mini compressor alongside other integrated parts that simplify installation while providing effective cooling solutions tailored for specific needs.

Types of Laser Coolers

Water chillers for laser cutters come equipped with features tailored specifically for industrial use cases such as adjustable flow rates and temperature settings that cater directly to user requirements. Additionally, some models may offer dual-circuit designs allowing simultaneous cooling of multiple devices—a feature highly sought after by busy workshops or laboratories needing versatility without sacrificing efficiency.

Another notable type is portable mini chillers like those produced by Arctic Active Cooling which serve as excellent options when space is at a premium or when users require mobile solutions adaptable across different machines or setups. These compact units are particularly appealing because they combine ease-of-use with robust performance capabilities—ensuring that even smaller operations can benefit from reliable cooling technology without breaking a sweat (or their budget).

The Science Behind Laser Water Cooling

Laser cooling technology has become a cornerstone in maintaining optimal operating conditions for high-performance equipment. At the heart of this technology is the laser water chiller, which effectively dissipates heat generated during operation, ensuring that lasers, such as CO2 laser cutters, function efficiently. Understanding the principles of water cooling systems and their advantages over traditional methods is crucial for anyone looking to enhance their laser performance.

Principles of Water Cooling

Water cooling operates on a straightforward principle: it uses water as a medium to absorb and transfer heat away from critical components. In a typical setup, a CO2 laser chiller circulates chilled water through various parts of the system, absorbing excess heat before returning to the chiller for re-cooling. This cycle not only maintains consistent temperatures but also prevents overheating that could lead to equipment failure or subpar performance.

The design of a water chiller for laser applications typically includes components like pumps, reservoirs, and heat exchangers that work in harmony to ensure effective thermal management. By utilizing water's high specific heat capacity, these systems can move large amounts of heat with minimal energy input compared to air cooling solutions. Consequently, this makes laser water chillers an ideal choice for demanding environments where precision is key.

Advantages of Water Cooling Systems

One significant advantage of using a laser cooler with water-based systems is their superior cooling efficiency compared to air-cooled alternatives. Water has a much higher thermal conductivity than air; thus, it can absorb and transport heat more effectively. This means that CO2 laser chillers can maintain lower temperatures while consuming less power—an essential factor in both industrial and medical applications.

Another benefit lies in the reduced noise levels associated with water cooling systems; they often operate more quietly than air coolers due to fewer moving parts required for airflow management. Additionally, since these systems are less affected by ambient temperature fluctuations, they provide stable cooling even in challenging environments—perfect for those who rely on precision cutting processes or intricate research applications.

Finally, when it comes to maintenance and longevity of equipment like CPU chillers or CO2 laser water chillers, water-based systems tend to have fewer issues related to dust accumulation or overheating risks associated with inadequate airflow found in air-cooled units. This translates into lower operational costs and increased reliability over time.

Comparing Water Cooling to Air Cooling

When comparing water cooling systems against traditional air coolers specifically designed for lasers, several key distinctions emerge that highlight the superiority of liquid-based solutions. For starters, while air coolers are generally easier and cheaper upfront due to their simpler designs and installation requirements, they often fall short in long-term efficiency when handling high-heat loads typical in industrial settings involving lasers.

Air-cooling relies heavily on ambient conditions; if temperatures rise outside or if there’s limited airflow around the unit itself (think dusty workshops), performance drops significantly—leading potentially costly downtime during critical operations like those involving CO2 lasers or other precision tools requiring constant temperature regulation. Conversely, a well-designed laser cooler can maintain optimal temperatures regardless of external factors thanks largely to its closed-loop system utilizing chilled liquid circulation.

In summary, investing in advanced technologies such as a mini-water chiller from Arctic Active Cooling offers numerous benefits over conventional methods—combining efficiency with ease-of-use tailored specifically towards modern manufacturing needs while ensuring your equipment remains operational at peak performance levels without breaking the bank on energy costs!

Applications of CO2 Laser Chillers

CO2 laser chillers are essential tools in various fields, providing efficient cooling solutions to enhance performance and precision. Their versatility allows them to be utilized in industrial settings, medical research, and even specialized laser cutting processes. Understanding the applications of a laser cooler can help businesses optimize their operations while ensuring longevity and reliability.

Industrial Use Cases

In industrial environments, CO2 laser chillers play a pivotal role in maintaining optimal operating temperatures for machinery. These systems are used extensively in manufacturing processes where high-powered lasers cut or engrave materials like metal, wood, and plastics. The efficiency of a water chiller for laser cutter applications ensures that equipment operates smoothly without overheating, reducing downtime and maintenance costs.

Moreover, industries such as automotive and electronics rely on precise cooling solutions to prevent thermal damage during production. The integration of a CO2 laser water chiller not only improves productivity but also enhances the quality of the final product by maintaining consistent temperatures throughout the manufacturing process. As companies strive for greater efficiency, investing in advanced cooling technologies becomes increasingly important.

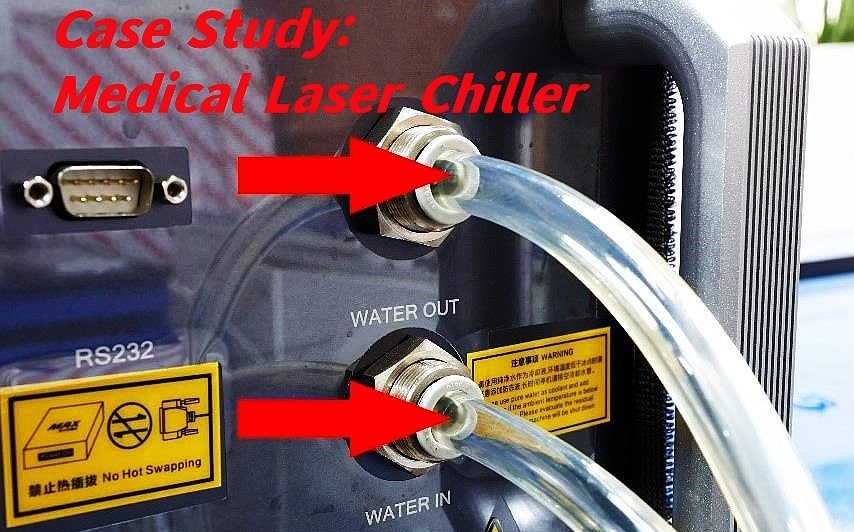

Medical and Research Applications

In the medical field, CO2 laser chillers are crucial for procedures that require precision and control over temperature-sensitive equipment. They are often used in dermatology for skin resurfacing treatments or surgical procedures where lasers operate at high power levels. A reliable laser cooler ensures that these devices maintain optimal performance while minimizing risks associated with overheating.

Research laboratories also benefit from using a water chiller for lasers during experiments that involve high-energy beams. Maintaining stable temperatures is vital for achieving accurate results in scientific investigations involving photonics or material science studies. With advancements like Arctic Active Cooling's Mini Water Chiller integrated into research systems, scientists can expect improved reliability from their equipment.

Benefits for Laser Cutting Processes

The benefits of utilizing CO2 laser chillers in cutting processes cannot be overstated; they significantly enhance both quality and efficiency. By employing a dedicated water chiller for laser applications, users can maintain consistent temperatures that prevent warping or distortion of materials being cut or engraved. This leads to cleaner edges and more precise cuts—qualities highly valued across various industries.

Additionally, effective cooling reduces wear on the cutting components themselves; this prolongs their lifespan while decreasing replacement costs over time. When paired with advanced technologies like Arctic's Mini Water Chiller system—designed specifically to integrate seamlessly into existing setups—users can achieve peak performance with minimal effort required on their part.

Exploring Arctic Active Cooling's Mini Water Chiller

When it comes to laser cooling solutions, Arctic Active Cooling's Mini Water Chiller stands out as a compact and efficient option tailored for various applications. This innovative chiller is designed specifically for environments where space is at a premium but performance cannot be compromised. With its advanced features and user-friendly integration, it has quickly become a favorite among professionals needing reliable cooling for their CO2 laser systems.

Features of the Mini Water Chiller

The Mini Water Chiller boasts an impressive array of features that make it ideal for use as a laser cooler in diverse settings. At its core, the unit utilizes a high-efficient refrigeration mini compressor with R134a coolant, ensuring optimal thermal management for equipment like CO2 laser cutters. Its design includes the smallest condenser and plate evaporator available, which not only enhances cooling efficiency but also minimizes energy consumption—an essential aspect when considering long-term operational costs.

Moreover, the chiller incorporates a filter drier and drive board within its compact structure, allowing seamless operation without excessive bulk. This sophisticated engineering ensures that users receive cutting-edge micro cooling solutions that are easy to install and maintain. Whether you're looking for a water chiller for laser cutting or simply need reliable temperature control for your machinery, this mini chiller delivers on all fronts.

Integration with Existing Systems

One of the standout features of Arctic Active Cooling's Mini Water Chiller is its ability to integrate smoothly with existing systems, making it an excellent choice for those who require flexibility in their setup. The device is designed specifically for customers who prefer modularity in their cooling subsystems, allowing them to assemble or integrate this water chiller into their machines effortlessly. With compatibility options available, users can connect their control boards directly to the BLDC compressor driver board found within the unit.

This level of integration not only simplifies installation but also empowers users to customize performance according to their specific needs—an invaluable trait when dealing with high-demand applications like CO2 laser operations. By enabling precise control over compressor speed through user-defined settings, this mini water chiller ensures optimal performance tailored specifically for each user's requirements.

Performance Benefits for Laser Users

For professionals utilizing CO2 lasers in industrial or research settings, choosing the right water chiller can significantly impact overall performance and efficiency. The Arctic Active Cooling Mini Water Chiller excels in maintaining stable temperatures that are crucial during extended operations; fluctuations can lead to compromised results or even damage equipment over time. By providing consistent cooling capabilities as a dedicated laser water chiller or CPU chiller solution, users can expect enhanced reliability from their tools.

Additionally, this mini water chiller contributes to improved processing speeds during tasks such as cutting or engraving by preventing overheating—ensuring that lasers operate at peak efficiency without interruptions caused by thermal stress. The result? Higher-quality outputs and increased productivity across various applications where precision matters most.

Choosing the Right Water Chiller for Lasers

Selecting the right water chiller for lasers is crucial to ensure optimal performance and longevity of your laser systems. With various options available, understanding the specific needs of your application can help you make an informed decision. This section will explore key factors to consider, popular models, and essential maintenance tips to keep your laser cooler running smoothly.

Factors to Consider When Selecting a Chiller

When choosing a water chiller for laser applications, several factors come into play. First and foremost, you should assess the cooling capacity required based on your specific CO2 laser chiller’s power output and operational demands. Additionally, consider the temperature range that your system must maintain; some laser water chillers are designed for extreme conditions while others are more suited for standard environments.

Another important aspect is the type of coolant used in the system. For instance, CO2 laser water chillers typically utilize R134a or similar refrigerants that provide efficient heat exchange without compromising performance. Lastly, evaluate integration capabilities with existing equipment; a well-designed water chiller should seamlessly connect with your current setup without extensive modifications.

Popular Models and Features

There are numerous models of laser coolers on the market today that cater specifically to different needs within industrial and medical applications. Notable examples include Arctic Active Cooling's Mini Water Chiller, which boasts a compact design yet delivers high efficiency through its advanced refrigeration components. Many users appreciate features like adjustable temperature controls and built-in monitoring systems that enhance usability.

Other popular options include larger industrial-grade water chillers designed for high-output CO2 lasers or those used in heavy-duty production environments. These models often have robust filtration systems to prevent contaminants from affecting performance over time. When selecting a model, look out for additional features such as energy efficiency ratings and noise levels—important considerations if you’re operating in sensitive areas.

Maintenance Tips for Optimal Performance

To ensure that your water chiller for laser cutter operates at peak efficiency, regular maintenance is essential. Start by routinely checking coolant levels and topping them off when necessary; low coolant can lead to overheating issues that compromise both performance and safety of your equipment. Additionally, inspect filters regularly—clean or replace them as needed—to avoid blockages that could hinder airflow or cooling efficiency.

It's also wise to monitor temperatures closely during operation; any significant fluctuations may indicate underlying problems requiring immediate attention. Scheduling annual professional servicing can help identify potential issues before they escalate into costly repairs or downtime—particularly important in high-stakes environments where precision is key.

Lastly, familiarize yourself with any manufacturer-specific guidelines regarding maintenance routines tailored to your particular model of CO2 laser water chiller or CPU chiller system; adhering closely to these recommendations will maximize lifespan and effectiveness.

Conclusion

In the realm of modern manufacturing and technology, laser cooling solutions have emerged as indispensable tools for enhancing efficiency and performance. The laser cooler, particularly the CO2 laser chiller and laser water chiller, plays a crucial role in maintaining optimal operating temperatures for various applications. By ensuring that equipment remains cool, these systems not only prolong the lifespan of lasers but also improve precision in tasks like cutting and engraving.

Summary of Laser Cooling Benefits

Laser cooling technologies offer numerous benefits that significantly impact both industrial and research environments. For instance, a water chiller for laser cutter applications ensures consistent temperature control, which is vital for achieving high-quality results without overheating. Additionally, utilizing a CO2 laser water chiller can enhance energy efficiency while reducing operational costs—making it an attractive option for businesses looking to optimize their resources.

Innovations in Cooling Technology

The landscape of cooling technology is continuously evolving, with innovations that make systems more efficient and user-friendly. The development of compact solutions like Arctic Active Cooling's Mini Water Chiller showcases advancements in design and functionality that cater to specific needs within the industry. These mini chillers integrate sophisticated refrigeration components into a single unit, allowing users to harness cutting-edge micro cooling solutions tailored to their unique setups.

Future Trends in Laser Water Cooling Solutions

Looking ahead, the future trends in laser water cooling solutions are poised to focus on sustainability and smart technology integration. As industries strive for greener practices, innovations such as eco-friendly refrigerants will become increasingly important alongside advanced monitoring systems that provide real-time data analysis on performance metrics. Furthermore, enhanced compatibility with various equipment types—including CPU chillers—will ensure that users can seamlessly incorporate these water chillers into their existing setups while maximizing efficiency.