Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In an era where energy efficiency and sustainable practices are paramount, understanding rack refrigeration systems becomes essential. These systems not only provide effective cooling solutions but also contribute significantly to operational cost savings for businesses across various sectors. As we delve into the world of refrigeration rack technology, we'll explore its functionalities, benefits, and innovative applications that redefine how we approach refrigeration.

Understanding Rack Refrigeration Systems

So, what is a refrigeration rack? A refrigeration rack is a centralized system designed to manage multiple cooling units simultaneously, making it an ideal choice for large-scale operations like supermarkets and cold storage facilities. By utilizing a series of compressors and evaporators, these systems can efficiently maintain desired temperature levels across various zones while minimizing energy consumption.

Importance of Efficient Cooling Solutions

The importance of efficient cooling solutions cannot be overstated in today’s competitive market. Businesses must ensure their perishable goods remain fresh while keeping energy costs at bay; this is where rack refrigeration shines. With the right system in place, companies can achieve optimal temperature control and extend the shelf life of their products without breaking the bank.

Overview of Refrigeration Rack Technology

Refrigeration racks come equipped with advanced technology that enhances performance and reliability. From vapor compression to absorption systems, understanding what are the three types of refrigeration systems helps businesses make informed decisions about which technology best suits their needs. Additionally, innovations like chiller racks play a crucial role in optimizing cooling efficiency across different commercial environments.

What is a Rack Refrigeration System?

Rack refrigeration systems are essential components within the broader landscape of commercial cooling solutions. These systems utilize a centralized approach to refrigeration, allowing multiple refrigerated spaces to be serviced by a single system, making them highly efficient and effective. Understanding what a rack system is can help businesses optimize their cooling needs while minimizing energy consumption.

Definition of Rack Systems

A rack refrigeration system is defined as an assembly of interconnected components designed to provide cooling for various applications, particularly in commercial settings like supermarkets and warehouses. Essentially, it consists of multiple compressors and evaporators working together to maintain specific temperature ranges across different zones. By centralizing the refrigeration process, these systems can significantly reduce operational costs and improve overall efficiency.

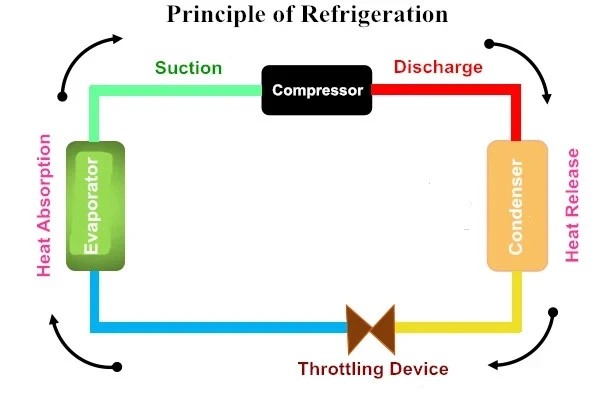

How Rack Refrigeration Works

So, how does rack refrigeration work? At its core, it operates on the principle of vapor compression, where refrigerant circulates through the system absorbing heat from the environment and releasing it elsewhere. This process involves compressing gas into a liquid state before passing it through evaporators that cool the air or products in designated areas—hence why many ask: What is a refrigeration rack? It’s all about maximizing efficiency while ensuring consistent temperatures.

Key Components of Rack Systems

The key components of rack systems include compressors, condensers, expansion valves, and evaporators—all working harmoniously to achieve optimal cooling performance. Compressors are responsible for circulating refrigerant throughout the system; condensers release heat absorbed by the refrigerant; expansion valves regulate flow; and evaporators cool down the air or products in refrigerated spaces. Understanding these elements helps clarify why many businesses choose rack refrigeration for their diverse needs.

The Three Types of Refrigeration Systems

Overview of System Types

Refrigeration systems can be broadly categorized into three main types: vapor compression, absorption, and cascade. Each type operates on distinct principles to achieve cooling and is chosen based on specific requirements such as efficiency, cost-effectiveness, and operational needs. Understanding these differences is crucial for businesses looking to optimize their rack refrigeration solutions.

Comparing Vapor Compression, Absorption, and Cascade Systems

Vapor compression systems are the most common type used in rack refrigeration setups due to their high efficiency and reliability. They work by compressing refrigerant gas in a closed loop system that absorbs heat from the environment before releasing it elsewhere. On the other hand, absorption systems utilize heat as an energy source instead of mechanical energy; they are often used in larger applications where waste heat is available or when electrical power is limited.

Cascade systems combine two or more refrigeration cycles using different refrigerants for different temperature ranges; this makes them ideal for applications requiring extreme cooling conditions. While vapor compression offers excellent performance for most commercial needs—like those found in chiller racks—absorption systems may be more suitable for specific industrial processes or locations with abundant waste heat resources.

Pros and Cons of Each Type

Each type of refrigeration system has its pros and cons worth considering when choosing a solution for your business's cooling requirements. Vapor compression systems are known for their energy efficiency and lower operational costs but may require more maintenance over time compared to other types. Absorption systems can be advantageous when electrical power is scarce but typically have higher initial costs due to complexity.

Cascade systems excel at providing extremely low temperatures but come with a higher upfront investment as well as increased maintenance demands due to their intricate design. Ultimately, selecting the right system depends on factors like application requirements, budget constraints, and long-term operational goals related to rack refrigeration.

Benefits of Rack Refrigeration

Rack refrigeration systems offer a multitude of advantages that make them an appealing choice for various industries. From energy efficiency to enhanced temperature control, these systems are designed to meet modern cooling demands while providing significant cost savings. Understanding these benefits can help businesses optimize their operations and improve their bottom line.

Energy Efficiency and Cost Savings

One of the standout features of rack refrigeration is its impressive energy efficiency, which translates directly into cost savings for businesses. By utilizing multiple compressors and advanced controls, what is a rack system? effectively minimizes energy consumption while maximizing cooling output. This not only reduces utility bills but also contributes to a more sustainable operation, making it an attractive option for environmentally conscious companies.

In addition to lower energy costs, rack refrigeration systems often require less maintenance compared to traditional units, further enhancing their cost-effectiveness. The durability and reliability of these systems mean fewer repairs and replacements over time, allowing businesses to allocate resources more efficiently. Ultimately, investing in a reliable refrigeration rack can yield substantial long-term savings.

Enhanced Temperature Control

When it comes to precision in temperature management, rack refrigeration systems excel in providing enhanced control over cooling conditions. These systems allow users to adjust temperatures with pinpoint accuracy, ensuring that perishable goods are stored under optimal conditions. What is a chiller rack? A chiller rack is specifically designed for applications requiring consistent temperature regulation across multiple zones.

The ability to maintain stable temperatures not only preserves the quality of products but also extends shelf life, reducing waste and losses for businesses. Furthermore, advanced monitoring technologies integrated into many modern racks enable real-time adjustments based on environmental changes or specific product needs—an essential feature for industries like food service or pharmaceuticals where compliance is paramount.

Versatility for Various Applications

Rack refrigeration systems are incredibly versatile and can be adapted to suit a wide range of applications across different sectors. Whether it's cold storage for food products or specialized environments like floral shops that require precise humidity control—what are the three types of refrigeration systems?—rack systems can cater to diverse requirements efficiently.

From large-scale commercial operations needing robust solutions to smaller setups requiring flexibility—rack refrigeration provides options that fit various business models seamlessly. This versatility makes them ideal not just in supermarkets or warehouses but also in niche markets where tailored cooling solutions are necessary, such as wine cellars or laboratories.

Exploring Chiller Racks

Chiller racks represent a pivotal technology in the realm of rack refrigeration, providing efficient cooling solutions for various commercial applications. These systems are designed to handle multiple refrigeration needs, making them ideal for businesses that require consistent temperature control across different environments. In this section, we will delve into what a chiller rack is, the engineering behind it, and its practical applications in commercial settings.

What is a Chiller Rack?

A chiller rack is a specialized refrigeration system that integrates multiple chillers into one cohesive unit. This design allows for greater efficiency and redundancy compared to traditional single-unit systems, ensuring that cooling needs are met even if one component fails. Essentially, when asking What is a refrigeration rack? or What is a rack system?, the chiller rack stands out as an advanced solution tailored for high-demand scenarios.

Chiller racks utilize multiple compressors and evaporators to distribute cooling effectively across various zones within a facility. This versatility makes them suitable for diverse applications, from food storage in supermarkets to climate-controlled environments in manufacturing plants. As businesses look for ways to optimize their operations, understanding what a chiller rack can offer becomes increasingly essential.

Engineering Behind Chiller Racks

The engineering of chiller racks involves sophisticated design principles aimed at maximizing energy efficiency while minimizing operational costs. Each component—compressors, condensers, evaporators—is meticulously selected and configured to work harmoniously within the system. When exploring what are the three types of refrigeration systems?, it's important to note that chiller racks typically fall under vapor compression systems due to their reliance on refrigerant cycles.

Advanced controls and monitoring technologies further enhance the performance of these systems by allowing real-time adjustments based on demand fluctuations. This adaptability not only improves energy efficiency but also extends the lifespan of critical components by reducing wear and tear during peak loads. In essence, robust engineering ensures that chiller racks deliver reliable performance day in and day out.

Use Cases in Commercial Environments

Chiller racks find numerous applications across various commercial sectors due to their flexibility and efficiency in managing temperature-sensitive products. Supermarkets often employ these systems to maintain optimal conditions for perishable goods such as dairy products, meats, and fresh produce—ensuring customers receive quality items every time they shop. Additionally, industries like pharmaceuticals rely on precision cooling provided by refrigeration racks to store sensitive medications at required temperatures.

Another exciting application involves using Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit within cold rooms designed specifically for florists or wholesale flower markets—maintaining optimal humidity and temperature levels essential for preserving freshness in flowers over extended periods. This innovative unit exemplifies how modern advancements in rack refrigeration can lead to significant improvements in both performance and sustainability across various business sectors.

The Role of Arctic Active Cooling

In the realm of rack refrigeration, Arctic Active Cooling has carved a niche with its innovative solutions that cater to a variety of cooling needs. Understanding what is a refrigeration rack and how systems like the Top-Mounted Monoblock Unit function can significantly enhance efficiency in commercial environments. This section delves into the features, applications, and benefits of this cutting-edge technology.

Features of the Top-Mounted Monoblock Unit

The Top-Mounted Monoblock Refrigeration Unit from Arctic Active Cooling is designed to streamline cooling processes for businesses. This unit combines advanced technology with user-friendly features, making it an ideal choice for those asking, What is a rack system? Its compact design not only saves space but also ensures that maintenance is straightforward and hassle-free, allowing operators to focus on their core business functions rather than worrying about complex refrigeration setups.

Additionally, this innovative unit delivers superior performance by maintaining optimal temperature and humidity levels critical for various applications. Whether you're looking at what are the three types of refrigeration systems or specifically focusing on chiller racks, this monoblock unit stands out for its energy efficiency and reliability. It’s engineered to handle fluctuations in demand effectively while minimizing energy consumption—an essential feature for any modern cooling system.

Applications in Cold Rooms and More

When considering what is a chiller rack, one must also explore its practical applications in real-world scenarios. The Arctic Active Cooling Top-Mounted Monoblock Unit shines in cold rooms where precise temperature control is paramount. From florists needing to keep fresh flowers vibrant to small businesses operating freezers or refrigerators, this unit adapts seamlessly across various environments.

Moreover, the versatility of these refrigeration racks allows them to be employed in diverse settings beyond just cold storage; they can be found in restaurants preserving ingredients or supermarkets displaying perishables efficiently. By integrating these units into their operations, businesses can ensure they meet both customer expectations and regulatory standards without breaking the bank on energy costs.

Reliability and Performance Benefits

Reliability is crucial when discussing any form of rack refrigeration system; downtime can lead to significant losses for businesses relying on consistent temperature management. The Arctic Active Cooling units boast exceptional performance benefits thanks to their robust construction and intelligent design features that prioritize durability alongside efficiency. For companies exploring what are the three types of refrigeration systems available today, these monoblock units represent a top-tier option that marries reliability with advanced technology.

Furthermore, users can expect reduced maintenance costs due to fewer moving parts compared to traditional systems—this means less time spent on repairs and more time focused on growth strategies! Ultimately, investing in such reliable solutions not only enhances operational efficiency but also contributes positively toward sustainability goals by lowering overall energy consumption across commercial facilities.

Conclusion

In summary, rack refrigeration systems are evolving to meet the increasing demands for efficiency and performance in various commercial applications. Understanding what is a refrigeration rack? and how it functions can significantly impact operational costs and effectiveness in cooling solutions. As businesses seek to optimize their refrigeration needs, the future of rack systems looks promising with advancements in technology and design.

The Future of Rack Refrigeration Systems

The future of rack refrigeration systems is poised for innovation as industries push for more sustainable and efficient cooling solutions. What is a rack system? It’s not just about keeping things cold anymore; it’s about doing so while minimizing energy consumption and maximizing reliability. With ongoing research and development, we can expect smarter systems that integrate IoT capabilities for real-time monitoring and control, ensuring optimal performance.

Innovations in Energy Efficiency

Energy efficiency remains at the forefront of innovations in refrigeration racks, with manufacturers constantly seeking ways to reduce energy consumption without compromising performance. What are the three types of refrigeration systems? Each type brings unique advantages that can be leveraged to achieve greater energy savings—whether through vapor compression technologies or absorption methods. As businesses become more environmentally conscious, these innovations will play a pivotal role in reducing carbon footprints while enhancing operational efficiency.

Maximizing Performance for Businesses

To maximize performance for businesses utilizing refrigeration racks, it’s essential to adopt advanced solutions like chiller racks that cater to specific needs across various sectors. What is a chiller rack? These specialized units provide enhanced temperature control while being versatile enough for different applications—from food storage to pharmaceuticals. By investing in high-performance options such as Arctic Active Cooling's Top-Mounted Monoblock Refrigeration Unit, businesses can ensure they maintain optimal conditions while enjoying unparalleled reliability.