Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In a world where freshness is paramount, cold storage refrigeration systems play a pivotal role in preserving the quality and safety of perishable goods. These systems not only keep food items chilled but also ensure that businesses can operate efficiently and meet consumer demands. Understanding what a cold storage refrigeration system entails is essential for any business that relies on temperature-sensitive products.

Unveiling Cold Storage Refrigeration Systems

So, what is a cold storage refrigeration system? At its core, it is an intricate network designed to maintain low temperatures for various applications, from food preservation to pharmaceutical storage. These systems utilize advanced technology to regulate temperatures, ensuring that products remain safe and viable over extended periods.

Why Cold Storage Matters for Businesses

Cold storage matters immensely for businesses as it directly impacts product quality and shelf life. Without efficient refrigeration systems, perishables can spoil quickly, leading to significant financial losses and potential health hazards. Therefore, investing in reliable cold storage solutions is not just beneficial; it's essential for maintaining customer trust and satisfaction.

Essential Components of Cold Refrigeration

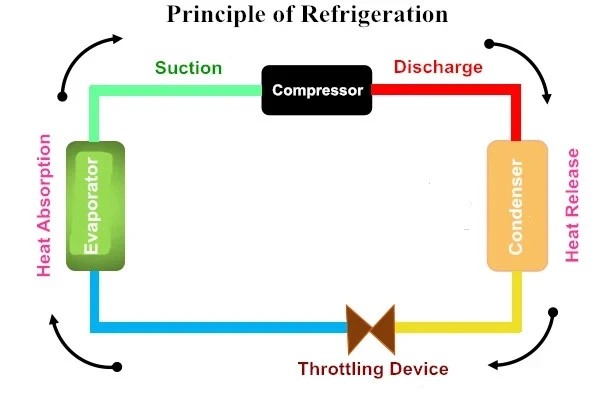

To grasp the full picture of cold refrigeration, one must understand its key components: compressors, condensers, evaporators, and refrigerants. Each element plays a vital role in the cooling process—compressors circulate refrigerants while condensers release heat absorbed from the environment. By grasping these components' functions, businesses can better appreciate how their cold storage refrigeration system operates effectively to meet their needs.

What is a Cold Storage Refrigeration System?

Cold storage refrigeration systems are essential for preserving perishable goods in various industries, from food and pharmaceuticals to chemicals and electronics. These systems maintain specific temperature ranges to ensure that products remain safe and viable for consumption or use. Understanding what a cold storage refrigeration system is can help businesses make informed decisions about their cooling needs.

Definition and Purpose

A cold storage refrigeration system is designed to cool and preserve products by maintaining low temperatures over extended periods. Its primary purpose is to prevent spoilage, extend shelf life, and ensure the safety of temperature-sensitive items. In essence, these systems are the backbone of supply chains that depend on keeping goods fresh.

How They Work in Commercial Settings

In commercial settings, cold storage refrigeration systems operate using advanced technology to control temperature and humidity levels effectively. Typically, they utilize a combination of compressors, evaporators, condensers, and refrigerants to achieve desired conditions. By continuously cycling refrigerants through these components, businesses can maintain optimal climates for their stored products.

Real-World Applications

Cold storage refrigeration systems find applications across various sectors including grocery stores, warehouses, hospitals, and restaurants. For instance, supermarkets rely on these systems to keep produce crisp while ensuring frozen foods remain solidly frozen. Additionally, pharmaceutical companies utilize specialized cold storage solutions to safeguard vaccines and medications that require strict temperature control.

What Refrigerants Are Used in Cold Storage?

Common Refrigerants in the Industry

In the realm of cold storage refrigeration systems, several refrigerants have become industry staples. Commonly used options include R-134a, R-404A, and R-410A, each offering unique properties suited for different applications. These refrigerants are favored for their efficiency in heat absorption and transfer, making them reliable choices for various commercial settings.

R-134a is often utilized in smaller refrigeration units due to its lower pressure requirements, while R-404A is popular for its effectiveness in low-temperature applications like ice cream storage. Meanwhile, R-410A has gained traction for its ability to operate at higher pressures, making it suitable for larger systems. As businesses evaluate what refrigerants are used in cold storage, they must consider not just performance but also compatibility with existing equipment.

Environmental Considerations

While selecting a refrigerant is crucial for operational efficiency, environmental considerations cannot be overlooked when discussing what is a cold storage refrigeration system. Many traditional refrigerants have been found to contribute significantly to ozone depletion and global warming potential (GWP). This has led to increased scrutiny and regulation surrounding their use.

As a result, many businesses are transitioning towards more environmentally friendly options such as hydrofluoroolefins (HFOs) or natural refrigerants like ammonia and CO2. These alternatives typically exhibit lower GWP values while still providing effective cooling performance. By understanding the environmental impact of various refrigerants, companies can not only comply with regulations but also enhance their corporate sustainability efforts.

Innovations in Refrigerants

The focus on sustainability has spurred numerous innovations within the field of cold storage refrigeration systems regarding refrigerant technology. Researchers and manufacturers are continually exploring new blends that reduce environmental impact while maintaining high energy efficiency levels. Innovations such as low-GWP synthetic blends aim to strike a balance between performance and ecological responsibility.

One exciting development includes the rise of magnetic refrigeration technology that utilizes solid-state materials instead of traditional fluids like those found in most cold refrigeration systems today. This emerging technology promises significant reductions in energy consumption while eliminating harmful emissions associated with conventional refrigerants altogether. As industries evolve towards greener practices, keeping an eye on these advancements will be essential for optimizing what is cold refrigeration across various applications.

What is Cold Refrigeration?

Cold refrigeration is a critical component of the cold storage refrigeration system, designed to maintain low temperatures for various applications. By effectively controlling temperature and humidity levels, cold refrigeration ensures that perishable goods remain fresh and safe for consumption. Understanding the intricacies of this system is essential for businesses relying on optimal conditions for their products.

Key Concepts Explained

At its core, cold refrigeration involves the transfer of heat away from a designated space to lower its temperature. This process typically utilizes refrigerants that absorb heat from the environment and release it elsewhere, creating a controlled climate ideal for storage. In commercial settings, what is a cold storage refrigeration system? It refers to specialized units engineered to provide consistent cooling where food and other perishables are stored.

The effectiveness of cold refrigeration hinges on several key concepts, including thermodynamics and heat exchange processes. These principles dictate how refrigerants operate within these systems, influencing efficiency and performance. Moreover, understanding these concepts helps businesses make informed choices about what refrigerants are used in cold storage.

Differences Between Cold Storage and Regular Refrigeration

While both cold storage and regular refrigeration serve similar purposes—keeping items cool—they differ significantly in scale and application. Cold storage systems are typically larger and designed for long-term preservation of bulk items like food products or pharmaceuticals, whereas regular refrigerators are intended for everyday household use with smaller volumes. What is a cold storage refrigeration system? It’s essentially an industrial version of your home fridge but built to handle much more demanding requirements.

Another difference lies in temperature ranges; cold storage units often operate at lower temperatures than standard refrigerators to accommodate specific needs such as freezing or chilling sensitive materials. Additionally, the technology used in these systems can vary widely based on their intended use—what are the three types of refrigeration systems? They include vapor-compression, absorption cooling, and thermoelectric systems tailored for different operational demands.

Importance for Perishable Goods

The importance of effective cold refrigeration cannot be overstated when it comes to perishable goods; it plays a vital role in reducing spoilage rates and extending shelf life. Without proper cooling mechanisms provided by a robust cold storage refrigeration system, food items can quickly deteriorate due to bacterial growth or enzymatic reactions triggered by higher temperatures. Businesses that prioritize reliable cooling solutions demonstrate commitment not only to quality but also customer satisfaction.

Moreover, maintaining optimal conditions through advanced technologies like Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit enhances operational efficiency while meeting regulatory standards concerning food safety. The versatility of these units allows them to cater to various industries—from restaurants storing fresh produce to pharmaceutical companies requiring strict temperature controls—underscoring their significance across sectors reliant on perishables.

In conclusion, understanding what is cold refrigeration provides insight into its critical role within the broader context of supply chain management involving perishable goods. As industries evolve towards more sustainable practices with innovations in what refrigerants are used in cold storage applications, businesses must stay informed about their options while ensuring they meet both consumer expectations and environmental concerns.

What Are the Three Types of Refrigeration Systems?

Cold storage refrigeration systems are essential for preserving perishable goods, and understanding their types helps businesses make informed decisions. There are three primary types of refrigeration systems: vapor-compression, absorption, and thermoelectric systems. Each type has its unique characteristics that cater to specific needs in cold storage applications.

Overview of Types

The first type, vapor-compression refrigeration systems, is the most commonly used in cold storage refrigeration systems. They work by compressing refrigerant gas, which then cools down as it expands within a closed loop. Absorption refrigeration systems utilize heat sources to drive the cooling process and are often found in locations with limited electricity access. Finally, thermoelectric refrigeration employs solid-state technology to create temperature differences through electrical currents—ideal for small-scale applications.

Advantages of Each System

Vapor-compression systems offer high efficiency and rapid cooling capabilities, making them suitable for large-scale cold storage needs. Absorption systems can be more environmentally friendly since they can use renewable energy sources like solar or waste heat; however, they tend to be less efficient than their vapor-compression counterparts. Thermoelectric units provide compactness and simplicity but may not deliver the same cooling power as larger systems; they're perfect for smaller units or specialized applications.

Choosing the Right System for Your Needs

When selecting a system from the three types of refrigeration systems available, consider factors such as your specific cooling requirements and budget constraints. If your business relies heavily on quick cooling processes for large quantities of goods, a vapor-compression system might be your best bet. However, if sustainability is key or you have access to alternative energy sources, absorption might be worth exploring—especially when combined with innovative solutions like Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit.

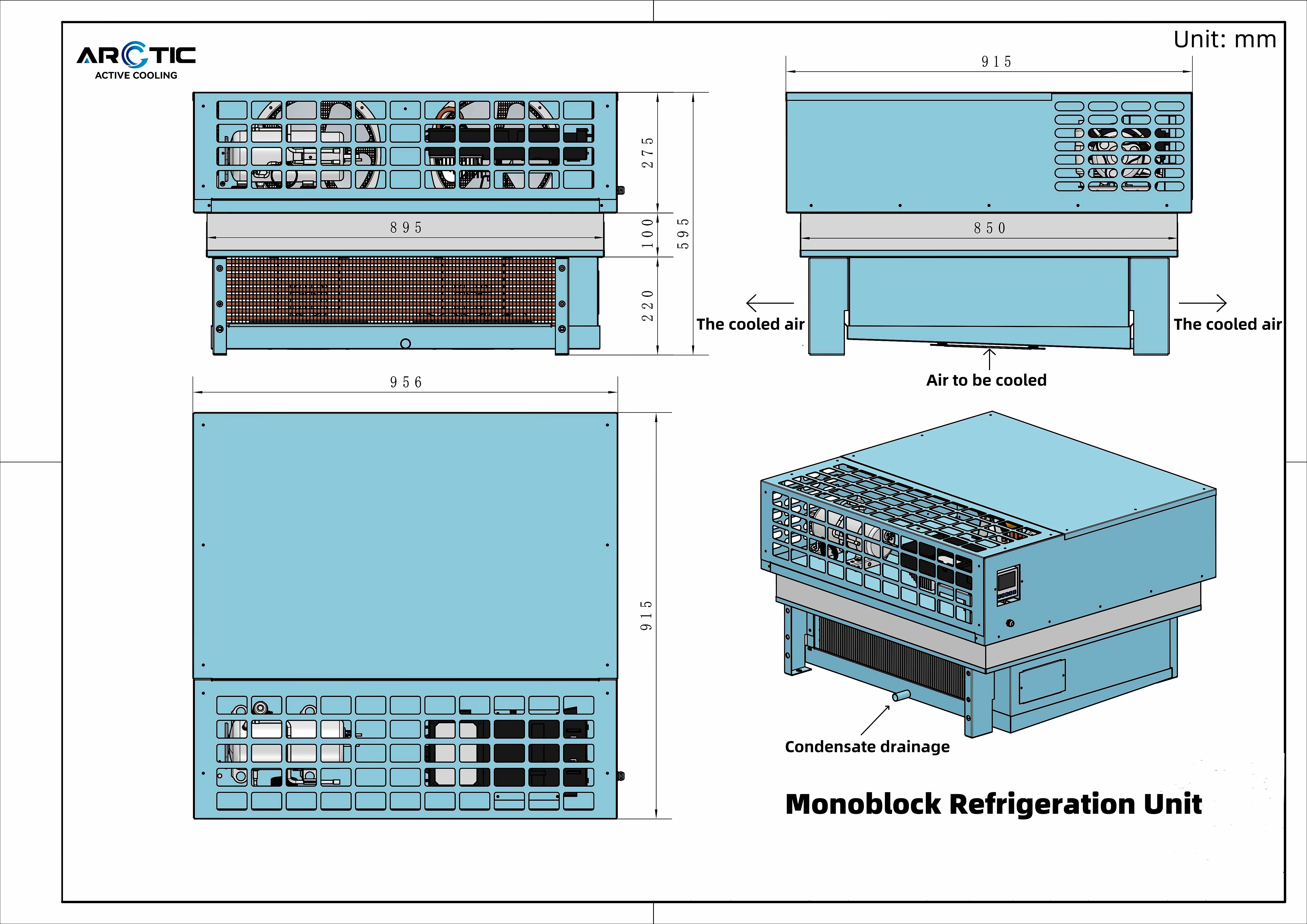

Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit

When it comes to cold storage refrigeration systems, the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit is a standout option. This innovative unit is designed specifically for commercial refrigerators, freezers, and small to mid-sized cold rooms, offering an all-in-one solution that combines efficiency and reliability. Businesses looking to enhance their cooling capabilities will find this unit meets the demands of modern applications while prioritizing performance and sustainability.

Features and Benefits

The Arctic Active Cooling unit boasts several impressive features that make it a top choice in the realm of cold storage refrigeration systems. Its compact design allows for easy installation in various settings, while its powerful compressor ensures rapid cooling without sacrificing energy efficiency. Additionally, this system utilizes advanced technology to monitor temperature fluctuations, providing optimal conditions for perishable goods and minimizing spoilage.

One of the main benefits of this refrigeration unit is its versatility; it can be tailored to meet specific business needs across different industries. Whether you're managing a bustling grocery store or running a small restaurant, this monoblock system can adapt accordingly. Furthermore, the energy-saving capabilities help businesses reduce operational costs without compromising on quality—an essential factor when considering what refrigerants are used in cold storage applications.

Applications in Cold Storage

The Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit finds various applications within cold storage environments due to its robust design and functionality. It excels in preserving food items such as meats, dairy products, fruits, and vegetables by maintaining consistent temperatures that prevent spoilage. Additionally, it serves well in pharmaceutical settings where temperature control is crucial for medication preservation.

This refrigeration unit also caters to businesses involved in logistics and distribution by ensuring that products remain fresh during transit or while stored in warehouses. With its ability to operate efficiently under varying load conditions, it's ideal for facilities with fluctuating inventory levels—making it an essential component of any effective cold storage refrigeration system strategy. The versatility extends beyond food; it can also support other temperature-sensitive goods like flowers or chemicals.

Why It Stands Out

What sets the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit apart from other options on the market? First off, its exceptional energy efficiency reduces both environmental impact and operating costs—qualities increasingly important as businesses seek sustainable solutions amid growing concerns about climate change related to what refrigerants are used in cold storage systems.

Moreover, its user-friendly design simplifies maintenance tasks while enhancing reliability over time—a significant advantage when considering what is cold refrigeration technology today compared with past models. This unit not only meets industry standards but often exceeds them with innovative features that ensure optimal performance across diverse applications.

In summary, whether you’re pondering what is a cold storage refrigeration system or exploring what are the three types of refrigeration systems available today—the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit emerges as a clear leader poised to meet your business's needs effectively.

Conclusion

As we wrap up our exploration of cold storage refrigeration systems, it’s clear that these systems are vital for businesses that rely on preserving perishable goods. Understanding what a cold storage refrigeration system entails is crucial for optimizing operations and ensuring product quality. From food services to pharmaceuticals, the importance of effective refrigeration cannot be overstated.

Understanding Refrigeration System Importance

The significance of a cold storage refrigeration system lies in its ability to maintain optimal temperatures for various products, preventing spoilage and waste. Businesses must grasp what refrigerants are used in cold storage to make informed choices about their cooling solutions. Moreover, knowing the differences between cold refrigeration and regular refrigeration can help companies select the right system tailored to their needs.

Environmental Impact of Refrigerants

In today's world, understanding the environmental impact of refrigerants is more critical than ever. Many traditional refrigerants used in cold storage have been linked to ozone depletion and global warming, prompting a shift towards more eco-friendly alternatives. As industries explore what refrigerants are used in cold storage, innovations are emerging that prioritize sustainability without compromising performance.

The Future of Cold Storage Technologies

Looking ahead, the future of cold storage technologies appears promising with advancements aimed at enhancing efficiency and reducing environmental footprints. The development of systems like Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit showcases how businesses can achieve unparalleled efficiency while maintaining reliability in their cooling processes. As industries continue to evolve, understanding what are the three types of refrigeration systems will be essential for making informed decisions about future investments.