Introduction

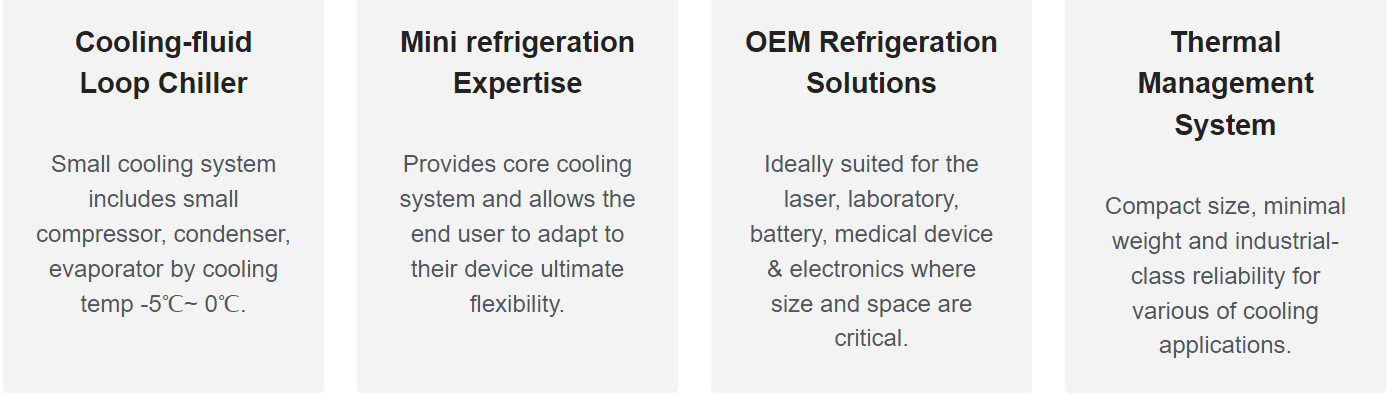

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In today's fast-paced world, the significance of cold storage refrigeration cannot be overstated. As industries ranging from food and beverage to pharmaceuticals expand, the demand for reliable cold storage solutions has surged dramatically. This growing importance is reshaping the landscape of Cold Storage Industrial Refrigeration Systems, making it essential for businesses to stay ahead of trends and innovations in this critical sector.

The Growing Importance of Cold Storage

Cold storage facilities play a pivotal role in preserving perishable goods, ensuring that products remain fresh and safe for consumption. With an increasing global population and a heightened focus on food safety, the need for efficient cold storage warehouses has never been greater. Moreover, businesses are recognizing that investing in advanced cold storage refrigeration systems can significantly reduce waste and enhance supply chain efficiency.

Innovations Reshaping Refrigeration Technology

Innovations in refrigeration technology are revolutionizing how we approach cold storage solutions. New advancements allow for better temperature control, energy efficiency, and overall system reliability—key factors for any effective cold storage room. For instance, smart refrigeration technologies are now being integrated into industrial refrigeration systems to monitor performance continuously and optimize energy use.

Understanding the Cold Storage Warehouse Landscape

Navigating the complexities of the cold storage warehouse landscape requires a comprehensive understanding of both current technologies and future trends. Facilities must adapt to new innovations while ensuring compliance with industry regulations surrounding temperature control and safety standards. As we delve deeper into this topic, it becomes clear that staying informed about developments in cold storage refrigeration is vital for businesses aiming to thrive in a competitive market.

Understanding Cold Storage Refrigeration

Cold storage refrigeration plays a pivotal role in preserving perishable goods, ensuring they remain fresh and safe for consumption. This specialized refrigeration system is crucial for various industries, including food service, pharmaceuticals, and biotechnology. By maintaining optimal temperatures, cold storage systems help reduce spoilage and waste while extending the shelf life of products.

What is Cold Storage Refrigeration?

Cold storage refrigeration refers to the technology and systems used to maintain low temperatures in storage facilities designed for perishable items. These systems can range from large-scale cold storage warehouses to smaller cold storage rooms within businesses. The primary goal of cold storage refrigeration is to create an environment that slows down the growth of bacteria, preserves quality, and ensures safety.

Cold Storage Industrial Refrigeration Systems are specifically designed for commercial applications where temperature control is critical. These systems often utilize advanced technologies that provide precise temperature regulation tailored to the specific needs of different products. Understanding these systems' nuances helps businesses select the right solutions for their cold storage needs.

Key Components of Cold Storage Systems

A typical cold storage refrigeration system consists of several key components that work together seamlessly to maintain desired temperatures. These components include compressors, condensers, evaporators, expansion valves, and insulation materials that minimize heat transfer from outside sources. Each element plays a vital role in ensuring efficient operation and reliability in maintaining the appropriate environment within a cold storage room or warehouse.

In addition to these main components, monitoring devices are essential for tracking temperature fluctuations and ensuring compliance with safety standards. Advanced sensors can alert operators if temperatures deviate from set parameters, allowing quick intervention before product quality is compromised. Together with innovative solutions like Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit, which offers unmatched efficiency in cooling applications, these elements form a robust framework for effective cold storage refrigeration.

The Importance of Temperature Control

Temperature control is paramount in any cold storage refrigeration setup; even minor fluctuations can lead to significant losses in product quality or safety. Maintaining consistent temperatures helps prevent spoilage and extends shelf life while ensuring compliance with health regulations across various industries like food service or pharmaceuticals. A well-designed cold storage warehouse must prioritize effective temperature management as part of its operational strategy.

Moreover, modern Cold Storage Industrial Refrigeration Systems incorporate smart technology that allows real-time monitoring and adjustments based on environmental conditions or product requirements. This level of precision not only enhances efficiency but also reduces energy consumption—an increasingly important factor as businesses seek sustainable practices amidst rising operational costs. Ultimately, investing in robust temperature control mechanisms leads to better inventory management and improved profitability for companies relying on cold storage solutions.

Advances in Cold Storage Industrial Refrigeration Systems

The landscape of cold storage refrigeration is rapidly evolving, driven by technological advancements that enhance efficiency and reliability. Cold Storage Industrial Refrigeration Systems are now incorporating innovative features that not only optimize performance but also reduce energy consumption. These cutting-edge technologies are essential for businesses aiming to maintain the integrity of their products while meeting stringent regulatory standards.

Cutting-edge Technologies in Refrigeration

Recent developments in cold storage refrigeration include the integration of advanced sensors and IoT connectivity, which provide real-time monitoring and control capabilities. These technologies enable operators to track temperature fluctuations and adjust settings remotely, ensuring optimal conditions within the cold storage room. Furthermore, energy-efficient compressors and variable-speed drives are being utilized to minimize power consumption while maximizing cooling efficiency.

Another significant advancement is the use of natural refrigerants, such as ammonia and carbon dioxide, which offer a more environmentally friendly alternative to traditional refrigerants. This shift not only helps businesses comply with environmental regulations but also reduces their carbon footprint significantly. With these cutting-edge technologies, cold storage warehouses can ensure product safety while promoting sustainability.

Benefits of Smart Refrigeration Solutions

Smart refrigeration solutions are revolutionizing cold storage operations by providing enhanced control over temperature management and energy use. By employing automated systems that utilize machine learning algorithms, these solutions can predict equipment failures before they occur, allowing for proactive maintenance strategies in Cold Storage Industrial Refrigeration Systems. This predictive capability leads to reduced downtime and increased operational efficiency.

Moreover, smart refrigeration systems offer significant cost savings through optimized energy usage and reduced waste during cooling processes. Businesses can benefit from lower utility bills while maintaining compliance with industry standards for temperature control in their cold storage rooms or warehouses. The ability to analyze data trends also empowers operators to make informed decisions about inventory management and product rotation.

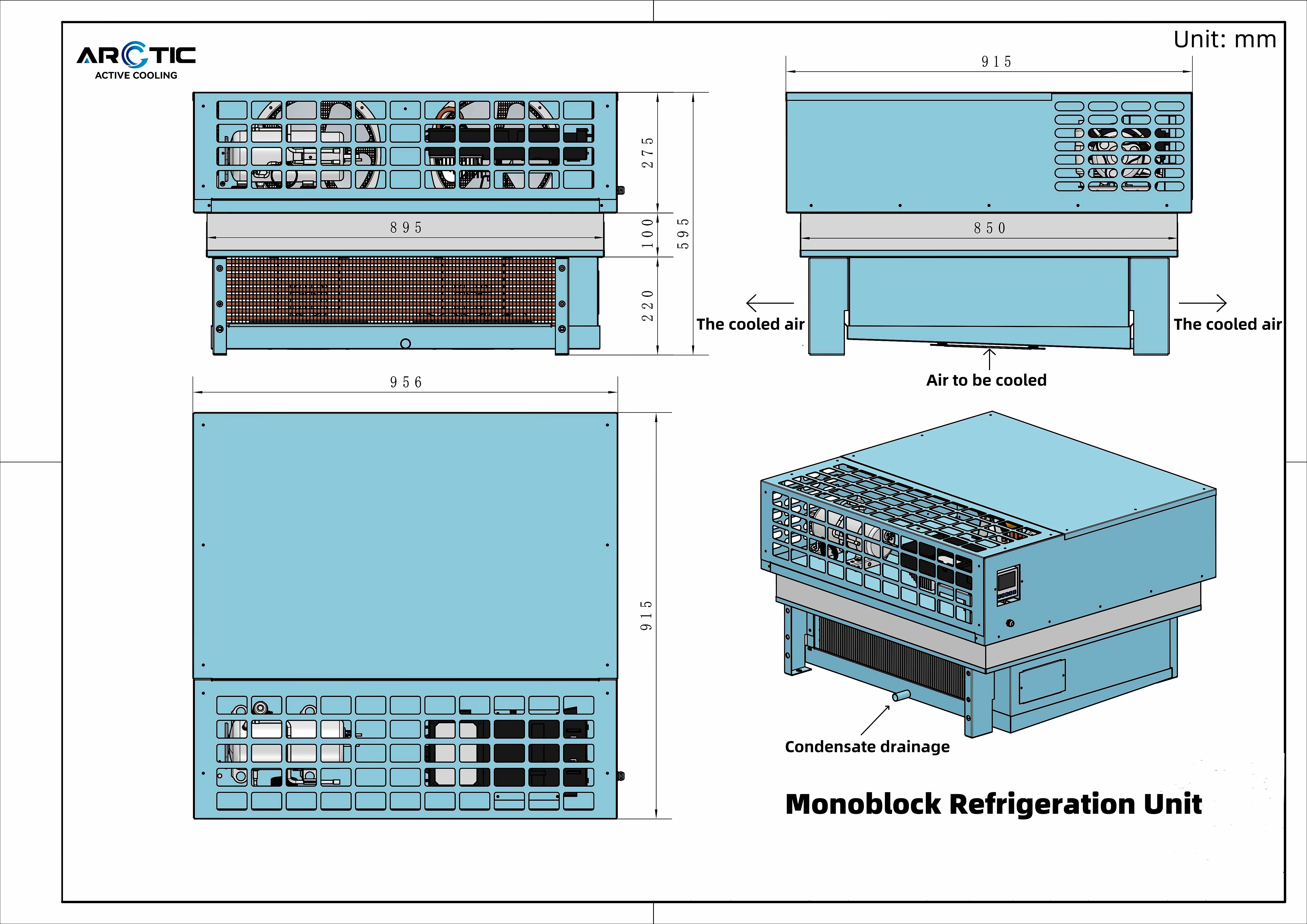

Case Study: Arctic Active Cooling’s Monoblock Refrigeration Unit

A prime example of innovation in cold storage refrigeration is Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit: Advanced Cooling for Cold Rooms. This all-in-one unit has been engineered specifically for commercial refrigerators, freezers, and small to mid-sized cold rooms, making it an ideal solution for various applications within a cold storage warehouse environment. Its design emphasizes unparalleled efficiency and reliability while addressing the unique demands of modern cooling applications.

The monoblock unit's compact design allows for easy installation without compromising performance or space within a facility's layout—a crucial factor when designing an efficient cold storage room. Additionally, its advanced cooling technology ensures consistent temperature maintenance even under varying load conditions, thus preserving product quality over time. For businesses looking for effective solutions in Cold Storage Industrial Refrigeration Systems, Arctic Active Cooling's innovative approach exemplifies how technology can drive both performance improvements and sustainability initiatives.

Designing an Efficient Cold Storage Room

Designing a cold storage room is no small feat; it requires careful consideration of various factors to ensure optimal performance and efficiency. The layout, size, and functionality of the cold storage refrigeration system must be meticulously planned to accommodate the specific needs of the products being stored. Additionally, compliance with industry standards and regulations for cold storage warehouses is crucial to maintaining quality and safety.

Factors to Consider in Cold Storage Design

When embarking on the design of a cold storage room, several factors come into play that can significantly impact its effectiveness. First, you need to assess the types of goods being stored; perishables like fruits or pharmaceuticals have different temperature requirements compared to frozen foods. Furthermore, consider the volume of inventory you expect to handle—this will dictate the size and configuration of your cold storage refrigeration system.

Another critical aspect is accessibility; ensuring that your cold storage room allows for efficient movement of goods can streamline operations and reduce handling time. You should also think about future scalability—will your business grow? Planning for expansion from the outset can save time and money down the line when you're ready to scale up your cold storage warehouse.

The Role of Insulation and Airflow

Insulation plays a pivotal role in maintaining temperature consistency within any cold storage room. High-quality insulation materials help prevent heat transfer, ensuring that your cold storage refrigeration system operates efficiently without unnecessary energy expenditure. Properly insulated walls, ceilings, and floors are essential for minimizing energy costs while maximizing product quality.

Airflow is equally important; effective circulation prevents hot spots and ensures uniform temperature distribution throughout the space. A well-designed airflow system helps maintain consistent conditions across all areas within your cold storage room, which is particularly vital for sensitive products that require precise climate control. Utilizing fans or air curtains can enhance airflow management while reducing energy consumption.

Energy Efficiency Best Practices

Implementing energy efficiency best practices in your cold storage refrigeration setup not only lowers operational costs but also contributes positively to environmental sustainability efforts. Start by selecting high-efficiency equipment such as Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit—this innovative solution combines performance with sustainability for commercial refrigerators and small-to-mid-sized cold rooms alike.

Regular maintenance checks are crucial; routine inspections help identify potential issues before they escalate into costly repairs or downtime in your cold storage warehouse operations. Additionally, consider incorporating smart technology solutions that monitor temperature fluctuations in real-time—these tools enable proactive adjustments that optimize energy usage without compromising product integrity.

In conclusion, designing an efficient cold storage room involves thoughtful planning around various factors including insulation, airflow management, and adherence to best practices in energy efficiency—all essential components for effective Cold Storage Industrial Refrigeration Systems.

Cold Storage Warehouse: Trends and Innovations

The landscape of cold storage warehouses is evolving rapidly, driven by the increasing need for efficient cold storage refrigeration solutions. As businesses strive to meet consumer demands for fresh and frozen products, innovations in Cold Storage Industrial Refrigeration Systems are becoming essential. This section explores emerging trends, automation technologies, and the benefits of modular systems that are shaping the future of cold storage rooms.

Emerging Trends in Cold Storage Warehouses

One of the most significant trends in cold storage warehouses is the shift toward sustainability and energy efficiency. Companies are increasingly adopting eco-friendly practices, such as utilizing natural refrigerants that have a lower environmental impact compared to traditional options. Additionally, advanced monitoring systems are being integrated into cold storage refrigeration systems to optimize energy usage while ensuring products remain at the desired temperatures.

Another trend gaining traction is the focus on food safety and compliance with stringent regulations. As consumer awareness grows regarding food quality and safety standards, businesses are investing in state-of-the-art cold storage solutions that guarantee optimal conditions for perishable goods. This includes implementing real-time temperature monitoring systems within their cold storage rooms to ensure compliance with health regulations.

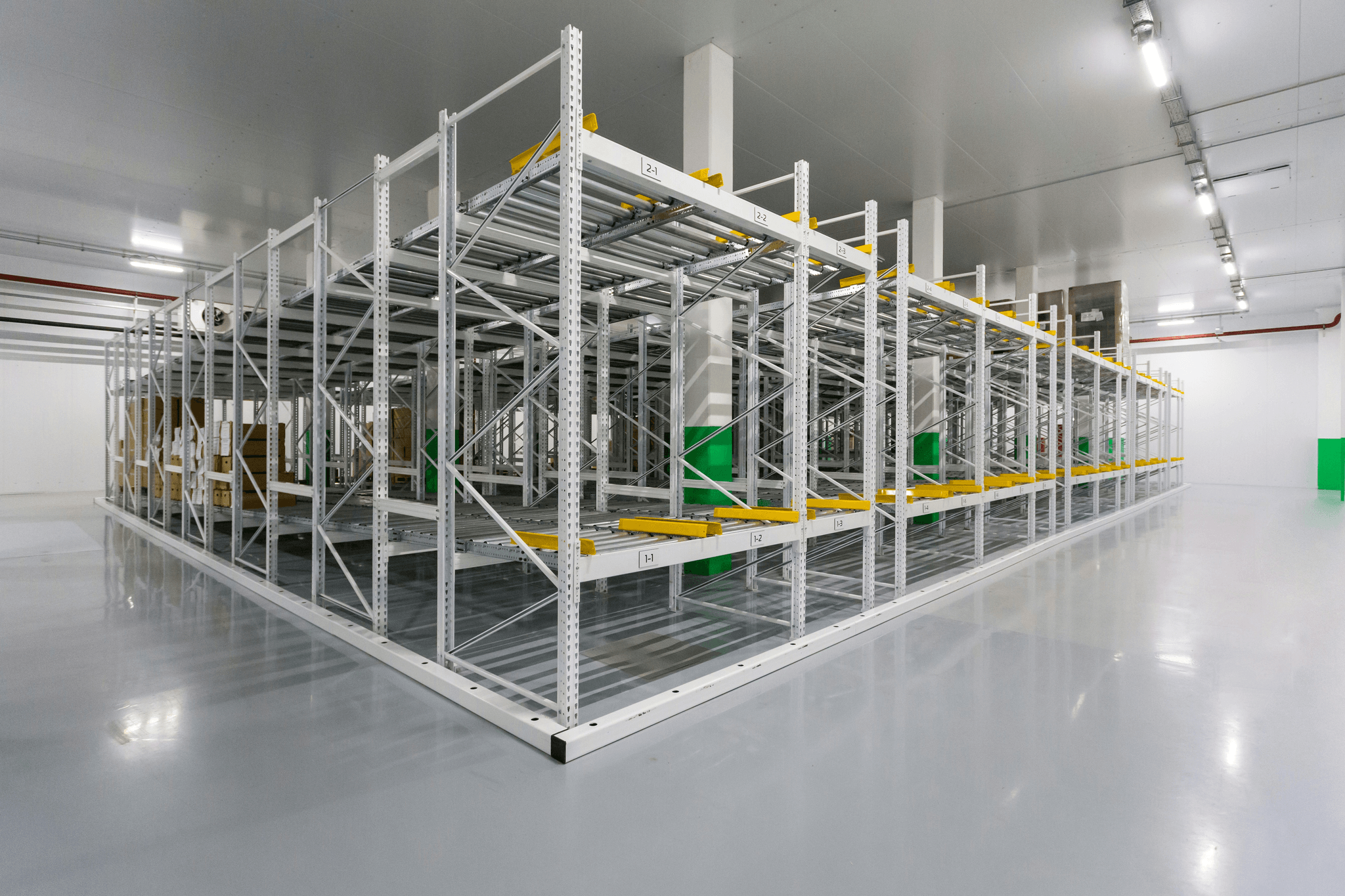

Finally, there’s a noticeable increase in demand for flexible warehouse designs that can accommodate various types of products. Cold storage warehouses are now being designed with adjustable shelving and modular configurations that allow companies to adapt their space quickly based on changing inventory needs. These emerging trends highlight a pivotal shift towards more responsive and responsible approaches in managing cold chain logistics.

Automation Technologies Revolutionizing Storage

Automation technologies are taking center stage in revolutionizing how cold storage warehouses operate today. From automated guided vehicles (AGVs) to robotic picking systems, these innovations enhance operational efficiency while minimizing human error within Cold Storage Industrial Refrigeration Systems. By automating routine tasks such as inventory management and order fulfillment, businesses can significantly reduce labor costs while improving accuracy.

Smart sensors play a crucial role in these automated environments by providing real-time data on temperature fluctuations and equipment performance within cold storage refrigeration systems. This data allows for proactive maintenance schedules that prevent costly downtime due to equipment failures or temperature breaches—ensuring product integrity remains uncompromised throughout its lifecycle.

Moreover, automation facilitates better space utilization within cold storage rooms by optimizing layout designs based on flow patterns and accessibility requirements. The implementation of these technologies not only streamlines operations but also enhances overall productivity—allowing companies to meet growing consumer demands without compromising quality or safety standards.

The Benefits of Modular Cold Storage Systems

Modular cold storage systems offer several advantages over traditional setups, making them an increasingly popular choice among businesses seeking flexibility and scalability within their operations. These systems can be easily expanded or reconfigured based on evolving inventory needs without requiring extensive renovations or downtime—ideal for industries experiencing fluctuating demand patterns.

Additionally, modular designs often come equipped with advanced features like integrated climate control technology tailored specifically for various products stored within each compartment of a larger facility using Cold Storage - Industrial Refrigeration principles. This level of customization ensures optimal conditions tailored uniquely to each type of perishable good stored inside their respective areas—ultimately enhancing product quality during transport or sale.

Furthermore, investing in modular solutions promotes cost savings through reduced energy consumption due to better insulation properties compared to conventional structures used previously across many facilities housing traditional refrigerated goods long-term! Overall benefits include increased operational efficiency alongside improved sustainability efforts aimed at reducing carbon footprints associated with standard practices found throughout typical warehouse environments today!

Best Practices for Maintaining Refrigeration Systems

Maintaining refrigeration systems is crucial for the efficiency and longevity of cold storage facilities. Regular upkeep not only ensures optimal performance but also helps prevent costly breakdowns that can disrupt operations in a cold storage warehouse. By following best practices, businesses can maximize the effectiveness of their cold storage refrigeration systems.

Regular Maintenance Tips for Cold Storage Systems

To keep your cold storage refrigeration systems running smoothly, establish a routine maintenance schedule. This should include checking refrigerant levels, inspecting seals and gaskets, and cleaning condenser coils to ensure efficient heat exchange. Additionally, regular temperature monitoring in your cold storage room is essential; fluctuations can indicate underlying issues that need immediate attention.

It’s also wise to invest in training staff on basic maintenance tasks and signs of malfunction within the Cold Storage Industrial Refrigeration Systems they operate. Empowered employees can help identify problems early on, preventing minor issues from escalating into major repairs or operational failures. Finally, consider using a preventive maintenance checklist tailored specifically for your cold storage refrigeration system to ensure nothing falls through the cracks.

Troubleshooting Common Refrigeration Issues

Even with regular maintenance, issues may arise within your cold storage refrigeration system that require troubleshooting. Common problems include inadequate cooling, unusual noises from the unit, or ice buildup around evaporator coils. When faced with these challenges, start by checking thermostat settings and ensuring that doors are sealing properly to maintain temperatures within the desired range.

If cooling remains insufficient despite these checks, it might be time to examine the compressor or expansion valves—key components of any Cold Storage Industrial Refrigeration System. In cases where you cannot pinpoint the issue yourself, don’t hesitate to reach out to a professional technician who specializes in industrial refrigeration systems; their expertise can save you time and money while ensuring compliance with industry standards.

Maintaining Compliance: Standards and Regulations

Compliance with local regulations is non-negotiable in maintaining an effective cold storage warehouse operation. Familiarize yourself with relevant safety standards related to refrigerants used in your Cold Storage - Industrial Refrigeration setup as well as guidelines governing temperature control—failure to comply could result in penalties or loss of product integrity due to improper conditions.

Regular audits of your cold storage room will help ensure adherence to these regulations while also identifying areas for improvement within your processes. Keeping thorough documentation regarding maintenance activities not only aids compliance but also provides valuable insights into operational efficiency over time—essential data when considering upgrades or expansions in equipment like Arctic Active Cooling’s innovative Top-Mounted Monoblock Refrigeration Unit.

By implementing these best practices for maintaining refrigeration systems, businesses can enhance their operational reliability while safeguarding product quality within their cold storage facilities.

Conclusion

In the ever-evolving landscape of cold storage refrigeration, the future holds exciting possibilities that promise to enhance efficiency and sustainability. As industries increasingly recognize the critical role of Cold Storage Industrial Refrigeration Systems, innovations will continue to emerge, addressing both operational challenges and environmental concerns. The integration of smart technologies and automated solutions will likely redefine how cold storage warehouses operate, ensuring they meet the growing demands for freshness and safety in food supply chains.

The Future of Cold Storage Refrigeration

Looking ahead, cold storage refrigeration is poised for transformative changes driven by technological advancements. With a focus on energy efficiency and reduced carbon footprints, businesses are likely to adopt more sustainable practices that align with global climate goals. Moreover, as consumer preferences shift towards fresh and organic products, the need for optimized cold storage rooms will become paramount in maintaining product integrity throughout the supply chain.

Innovative Technologies Shaping the Industry

Innovative technologies are at the forefront of reshaping Cold Storage - Industrial Refrigeration systems today. One standout example is Arctic Active Cooling's Top-Mounted Monoblock Refrigeration Unit, which combines performance with sustainability for commercial refrigerators and freezers. This all-in-one solution not only enhances cooling efficiency but also simplifies maintenance processes—making it a game-changer for businesses looking to optimize their cold storage warehouse operations.

Final Thoughts on Effective Cold Storage Solutions

In conclusion, effective cold storage solutions hinge on understanding both current trends and emerging technologies within the industry. By embracing innovations such as smart refrigeration systems and modular designs, businesses can ensure they remain competitive while meeting stringent regulatory standards. Ultimately, investing in robust cold storage refrigeration systems will be crucial for any organization aiming to thrive in an increasingly demanding market.