Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

Building a cold room can be a game changer for anyone looking to store meat safely and effectively. It raises the question: how to build a cold room for meat? With the right knowledge and materials, you can create an optimal environment that preserves the quality of your meat while ensuring safety.

Understanding Cold Room Basics

A cold room is essentially a controlled environment designed specifically for storing perishable items like meat. It maintains low temperatures, preventing spoilage and extending shelf life. Understanding how cold rooms function helps you appreciate their importance in food preservation, especially if you're asking, Can you store meat in a cold room?

Benefits of Building a Cold Room

The benefits of building a cold room are numerous; from cost savings on purchasing fresh meat to having complete control over storage conditions. Not only does it allow for bulk purchasing and storage, but it also minimizes waste by keeping your meats fresher longer. If you've ever wondered how you can build a cold room or if it's possible to make a meat cooler with an air conditioner, this guide will provide insights into those options.

Essential Materials for Meat Storage

To successfully create your own cold room, you'll need specific materials that ensure optimal temperature control and hygiene. Insulation is crucial to maintain low temperatures while avoiding energy waste; additionally, shelving units made of non-porous materials are ideal for storing various types of meat safely. If you're curious about how to make a meat cooler with an air conditioner, understanding these essential materials will set you on the right path.

Choosing the Right Location

Finding the right spot for your cold room is crucial to ensure optimal meat storage. The location affects not only the efficiency of cooling but also the overall maintenance and accessibility of your cold room. By carefully considering various factors, you can create an ideal environment for preserving meat.

Factors to Consider for Your Cold Room

When deciding on a location, consider factors like temperature fluctuations, humidity levels, and proximity to your kitchen or processing area. A space that maintains a consistent cool temperature is essential, as it directly impacts how you store meat effectively. Additionally, ensure that there’s sufficient space for ventilation and easy access to power sources needed for refrigeration units.

Another important aspect is safety; avoid areas prone to flooding or pests that could compromise your meat storage. If you're pondering how to build a cold room for meat, think about placing it in a basement or an insulated garage where temperatures are naturally lower. Lastly, take into account local regulations regarding food storage; compliance can save you from future headaches.

Ideal Locations for Meat Storage

The best locations typically include basements or dedicated outbuildings that are naturally cooler than other parts of your home. These spaces often have fewer temperature fluctuations and can be easily insulated for maximum efficiency when learning how to make a meat cooler with an air conditioner. If you're considering options like converting an existing shed or garage into a cold room, make sure it's well-insulated and has adequate drainage.

Additionally, think about accessibility; you want your cold room near areas where you'll frequently transport meat in and out without hassle. This will streamline operations if you're running a small business or simply storing large quantities at home. Remember that proper placement can help maintain consistent temperatures essential for safe meat storage.

Avoiding Common Pitfalls

One common mistake people make when building a cold room is underestimating insulation needs; inadequate insulation leads to higher energy costs and inconsistent temperatures—definitely not what you want while figuring out how to build a cold room for meat! Ensure walls, floors, and ceilings are properly insulated with materials designed specifically for refrigeration applications.

Another pitfall is neglecting airflow; without proper circulation, certain areas may get colder than others leading to uneven cooling—an absolute no-no when storing perishable items like meat! Installing fans or using Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit can help maintain even temperatures throughout the space while ensuring reliability.

Lastly, don’t forget about moisture control! High humidity levels can foster bacterial growth on meats which could compromise their safety—so installing dehumidifiers might be worth considering if you're serious about how you store your meats long-term.

Designing Your Cold Room Layout

Designing an effective cold room layout is crucial for maximizing efficiency and ensuring proper meat storage. A well-thought-out design not only enhances accessibility but also maintains optimal temperature and airflow, critical factors in preserving meat quality. Whether you're wondering how to build a cold room for meat or exploring DIY options, focusing on layout will set the foundation for success.

Optimal Space Utilization Techniques

When considering how to build a cold room, space utilization is key. Start by measuring your available area and planning for vertical storage solutions such as shelves and racks, which can help you make the most of limited floor space. Additionally, consider using modular units that can be rearranged as your storage needs evolve; this flexibility allows you to adapt your space over time without major renovations.

Creating designated zones within the cold room can also improve organization and efficiency. For example, group similar items together—like sausages, steaks, or poultry—to streamline access during busy times. Remember that thoughtful space allocation not only makes it easier to find what you need but also helps maintain consistent temperatures throughout the room.

Importance of Airflow and Circulation

Airflow is another critical aspect when asking yourself: Can you store meat in a cold room? The answer is yes—provided there’s adequate circulation! Proper airflow prevents hotspots where bacteria can thrive and ensures that every cut of meat stays at a safe temperature.

Incorporating fans into your design can significantly enhance air movement within the space. This helps distribute cool air evenly and reduces moisture buildup that could lead to spoilage or freezer burn on your meats. When learning how to make a meat cooler with an air conditioner, remember that maintaining optimal circulation will be just as important as cooling capabilities.

Creating a Functional Storage System

To truly master how to build a cold room for meat, establishing an organized storage system is essential. Consider using clear bins or labels so you can easily identify what’s inside each container—this saves time when searching for specific cuts of meat while reducing the risk of cross-contamination between different types of products.

Incorporate adjustable shelving units that allow you to modify heights based on what you're storing at any given time; this adaptability means your system remains functional even as inventory changes seasonally or based on demand. Keep in mind that if you're thinking about whether you can make a meat cooler with an air conditioner alone, integrating shelving into your design will provide additional support for temperature management alongside cooling systems like Arctic Active Cooling's Top-Mounted Monoblock Refrigeration Unit.

Insulation and Climate Control

When considering how to build a cold room for meat, insulation and climate control are crucial aspects that cannot be overlooked. The right materials and systems ensure that your cold room maintains a consistent temperature, preserving the quality of the meat stored within. Let's dive into the best insulation options, temperature maintenance strategies, and how to effectively use cooling units.

Best Insulation Materials for Cold Rooms

Choosing the right insulation materials is vital in ensuring your cold room operates efficiently. Common choices include polyurethane foam, polystyrene panels, and fiberglass batts; each offers varying R-values that indicate their thermal resistance. Selecting high-quality insulation not only helps maintain a stable environment but also reduces energy costs associated with running your cold room.

Can you store meat in a cold room? Absolutely! However, without proper insulation, you may struggle to maintain optimal temperatures necessary for safe storage. When exploring how to build a cold room for meat, prioritize materials that can withstand humidity while providing excellent thermal performance.

Additionally, consider using vapor barriers alongside your insulation materials to prevent moisture buildup that could compromise your meat's quality. This combination ensures you create an effective barrier against external temperature fluctuations while keeping your stored goods safe from spoilage.

How to Maintain Proper Temperature

Maintaining the proper temperature in your cold room is essential for preserving meat quality and safety. Ideally, the temperature should be kept between 28°F (-2°C) and 32°F (0°C) for optimal storage conditions. Regularly monitoring these temperatures with reliable thermometers or digital sensors will help you stay on top of any fluctuations.

If you're wondering how you can build a cold room effectively, implementing an efficient climate control system is key. This involves not just selecting quality insulation but also ensuring adequate airflow throughout the space to avoid hot spots where temperatures can rise unexpectedly.

Moreover, utilizing backup systems or alarms can alert you if temperatures deviate from the desired range—giving you peace of mind when storing valuable meats. With these strategies in place, you'll be well-equipped to maintain ideal conditions inside your new cold room.

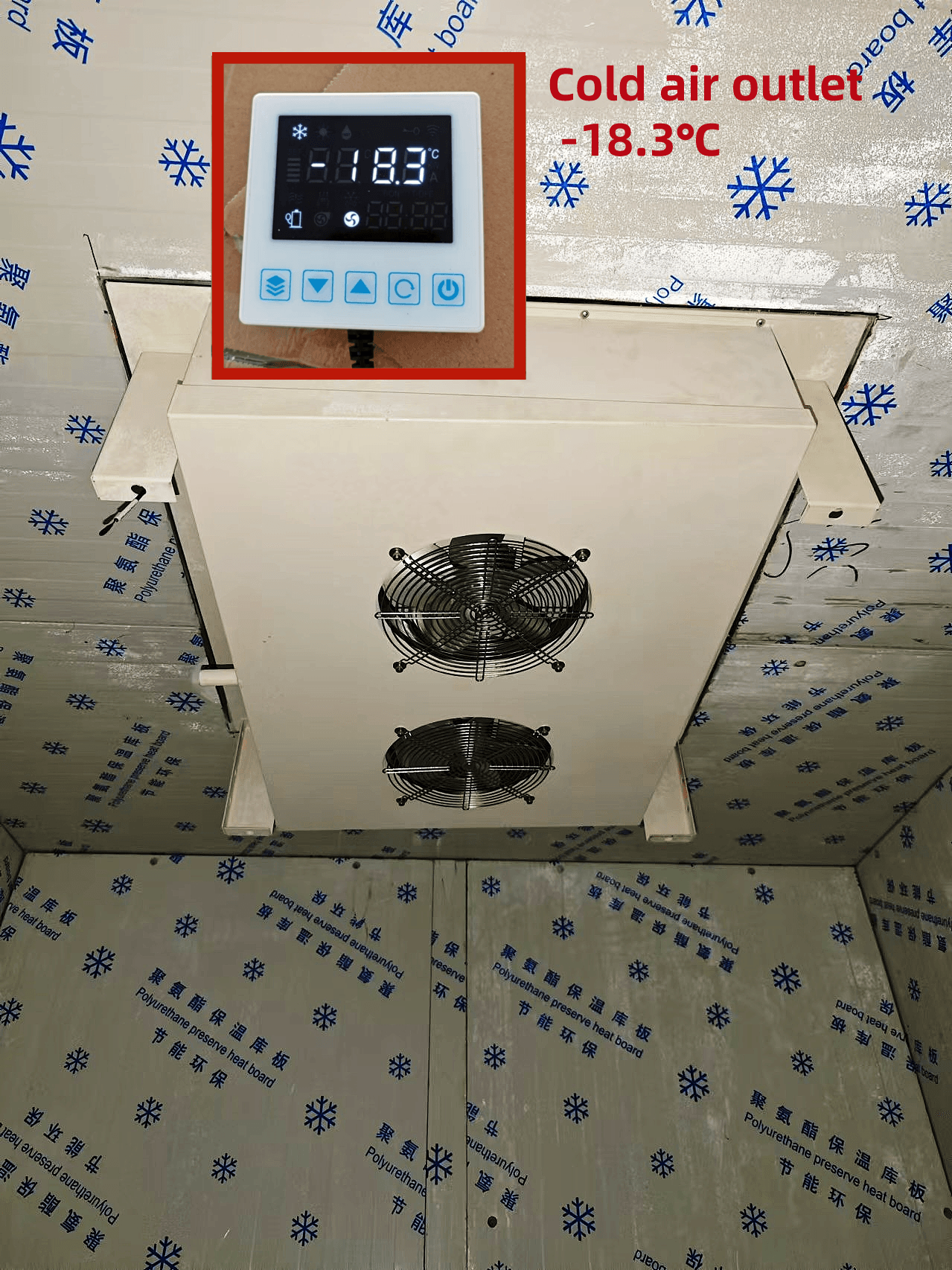

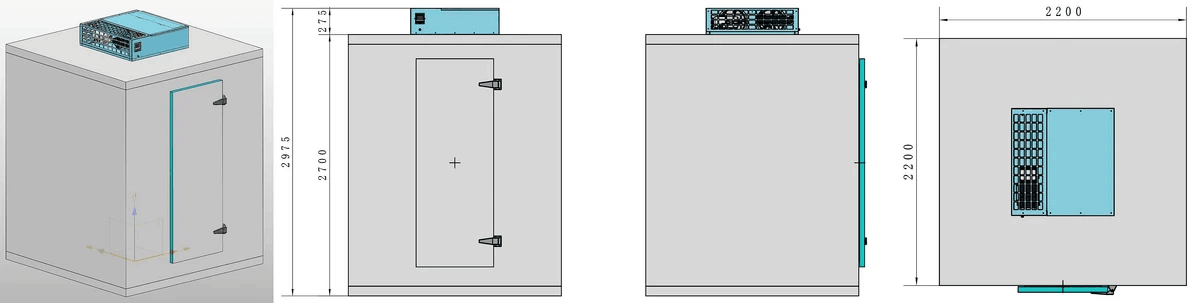

Using Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit

One of the best options available for maintaining consistent temperatures in your cold room is the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit. This innovative unit is designed specifically for small to mid-sized applications like yours—providing both reliability and efficiency at every turn. With its all-in-one design, it simplifies installation while delivering powerful cooling performance tailored to meet modern demands.

Can you make a meat cooler with an air conditioner? While it's possible to repurpose an air conditioning unit as part of your setup, specialized refrigeration solutions like those from Arctic Active Cooling offer superior results tailored specifically for food preservation needs. Not only do they keep temperatures stable but they also enhance energy efficiency compared to standard AC units.

Incorporating this advanced cooling technology into your design will ensure that you're not just building any old space—but rather creating an effective environment where you can safely store meats without worry about spoilage or safety concerns down the line.

DIY vs. Professional Help

When it comes to building a cold room for meat, the choice between doing it yourself or hiring a professional can be daunting. Understanding your own skills and the complexity of the project is crucial. If you're asking yourself, How can I build a cold room? consider your experience level, available tools, and time commitment before diving in.

When to Consider Professional Installation

Professional installation is often advisable for those who are unsure about how to make a meat cooler with an air conditioner or lack experience in construction projects. If you have specific requirements regarding temperature control and insulation that need expert knowledge, hiring professionals ensures these are met effectively. Additionally, if your local regulations require permits or inspections, professionals will navigate these complexities more smoothly than most DIYers.

Steps to Build Your Own Cold Room

If you're determined to take on the challenge of how to build a cold room for meat yourself, start by planning your layout meticulously. First, select an appropriate location with easy access and minimal exposure to heat sources. Next, gather essential materials such as insulation panels and refrigeration units; consider using Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit for optimal performance in temperature regulation.

Once you have everything ready, construct the frame and install insulation before setting up your cooling unit according to manufacturer guidelines. After that, ensure proper airflow by placing shelves strategically within the space; this will help maintain consistent temperatures throughout the cold room. Finally, conduct thorough tests on temperature stability before storing any meat.

Comparing Costs and Benefits

When comparing costs between DIY projects and professional installations for building a cold room for meat storage, it's essential to factor in both monetary expenses and time investment. While DIY might seem cheaper initially due to material costs alone, remember that mistakes can lead to higher expenses down the line—especially if you need repairs or adjustments afterward!

On the other hand, professional installation may come with higher upfront fees but often guarantees efficiency and reliability from day one—saving you headaches later on. Ultimately, weighing these options against your budgetary constraints will help determine whether you should roll up your sleeves or call in experts.

Maintenance and Safety Considerations

Building a cold room for meat is just the beginning; maintaining it is crucial for food safety and quality. Regular maintenance ensures your cold room operates efficiently, keeping temperatures stable and minimizing energy costs. By implementing a few simple checks, you can prolong the life of your equipment and ensure your meat storage remains safe.

Regular Checks for Efficiency

To keep your cold room running smoothly, perform regular checks on the refrigeration unit, insulation, and temperature levels. Monitoring these elements will help you identify any potential issues before they escalate into costly repairs or spoilage of stored meat. Remember to check the Arctic Active Cooling unit as well; it’s designed for optimal performance in commercial settings, ensuring that your cold room maintains a consistent temperature essential for meat preservation.

It's also important to regularly inspect door seals and gaskets to prevent cold air from escaping. If you notice any gaps or wear, replace them immediately to maintain efficiency in how to build a cold room for meat. By staying proactive with these checks, you can avoid unnecessary downtime and ensure that your investment remains worthwhile.

Preventing Cross-Contamination

Cross-contamination is one of the biggest threats when storing meat in a cold room. To mitigate this risk, designate specific areas within the space for different types of meat—such as red meats, poultry, and seafood—to prevent any cross-contact between them. This practice not only enhances food safety but also helps maintain the quality of each type of meat.

Additionally, always store raw meats below cooked or ready-to-eat items to further minimize contamination risks. When considering how to make a meat cooler with an air conditioner or building a dedicated cold room, remember that cleanliness is key; implement strict hygiene protocols like regular cleaning schedules and proper handling techniques to keep everything safe.

How to Ensure Safe Meat Storage

Ensuring safe storage conditions goes beyond just keeping things cool; it involves monitoring temperatures closely and understanding best practices in food safety. For optimal results when learning how can I build a cold room?, aim for temperatures between 28°F (-2°C) and 32°F (0°C) for most types of meats while using reliable thermometers positioned throughout the space.

Investing in an advanced cooling solution like Arctic Active Cooling's Top-Mounted Monoblock Refrigeration Unit can significantly enhance your ability to maintain these ideal conditions efficiently. Moreover, consider labeling all stored items with dates so you can easily track freshness—this small step makes it easier to rotate stock effectively while ensuring you're always serving high-quality products.

Conclusion

Building a cold room for meat is a rewarding project that can significantly enhance your food preservation efforts. By following the outlined steps, you can create an efficient and effective storage solution that meets your needs. Remember to focus on insulation, climate control, and proper layout for optimal performance.

Key Steps for Building a Cold Room

To learn how to build a cold room for meat, start by selecting the right location and ensuring it has adequate space and access to power sources. Next, design your layout with airflow in mind, as this will help maintain consistent temperatures throughout the room. Finally, invest in quality insulation materials and consider using advanced cooling solutions like Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit for reliable temperature control.

Expert Tips for Meat Preservation

When it comes to meat preservation, maintaining the right temperature is crucial; ideally between 28°F and 32°F (-2°C to 0°C). Regularly check your cold room's efficiency with thermometers or smart monitoring devices to ensure optimal conditions are maintained. Additionally, if you're wondering how you can make a meat cooler with an air conditioner, consider using a modified window unit; just be sure it’s properly insulated and sealed.

Addressing Common Cold Room Questions

Many people ask: Can you store meat in a cold room? The answer is yes! A well-designed cold room provides an excellent environment for storing various types of meat safely. If you're curious about how to make a meat cooler with an air conditioner or need guidance on building one from scratch, remember that proper insulation and airflow are key factors in achieving success.