Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the world of HVAC systems, solenoid valves play a pivotal role in regulating the flow of refrigerants, ensuring that your cooling systems operate efficiently. Among these, the liquid line solenoid valve is essential for maintaining optimal performance and protecting system components from potential damage. Understanding the liquid line solenoid valve purpose can help users appreciate its critical functions and enhance their HVAC knowledge.

Understanding Solenoid Valves in HVAC

Solenoid valves are electromechanical devices that control fluid flow through pipelines using an electromagnetic coil. In HVAC systems, they act as gatekeepers, managing the flow of refrigerants based on specific conditions within the system. By grasping what a liquid line solenoid valve is for, it's easier to see how these valves contribute to overall system efficiency and reliability.

Importance of Liquid Line Solenoid Valves

The importance of liquid line solenoid valves cannot be overstated; they are crucial for preventing issues like liquid flooding and compressor damage within HVAC systems. By controlling refrigerant flow effectively, these valves ensure that cooling processes run smoothly while minimizing energy consumption. Recognizing what is the main function of a solenoid valve helps users understand its impact on system longevity and performance.

Overview of Their Functions

Liquid line solenoid valves serve several key functions within an HVAC setup: they regulate refrigerant flow, protect critical components from potential harm, and enhance overall system efficiency. Moreover, understanding where to install a liquid line solenoid valve can significantly influence its effectiveness in maintaining optimal operating conditions. By comprehending these functions, users can better appreciate how these essential components work together with other elements such as the liquid line service valve to ensure seamless operation.

What is a Liquid Line Solenoid Valve?

When exploring HVAC systems, one component that often comes up is the liquid line solenoid valve. This critical device plays a pivotal role in managing refrigerant flow and ensuring system efficiency. Understanding its purpose and function can help you appreciate how it contributes to optimal HVAC performance.

Definition and General Purpose

A liquid line solenoid valve is an electromechanical device designed to control the flow of refrigerant within an HVAC system. Typically found in the liquid line of refrigeration circuits, its primary purpose is to regulate the refrigerant flow based on system demands. When discussing what a liquid line solenoid valve is for, it's essential to recognize that it acts as a gatekeeper, allowing or stopping refrigerant from entering specific areas of the system as needed.

Key Components of a Solenoid Valve

The construction of a liquid line solenoid valve consists of several key components that work together seamlessly. At its core, there’s an electromagnetic coil which, when energized, creates a magnetic field that moves the valve's internal mechanism—often referred to as the plunger or armature—to open or close the passageway for refrigerant flow. Other crucial parts include body housing made from durable materials, seals for preventing leaks, and terminals for electrical connections that facilitate operation.

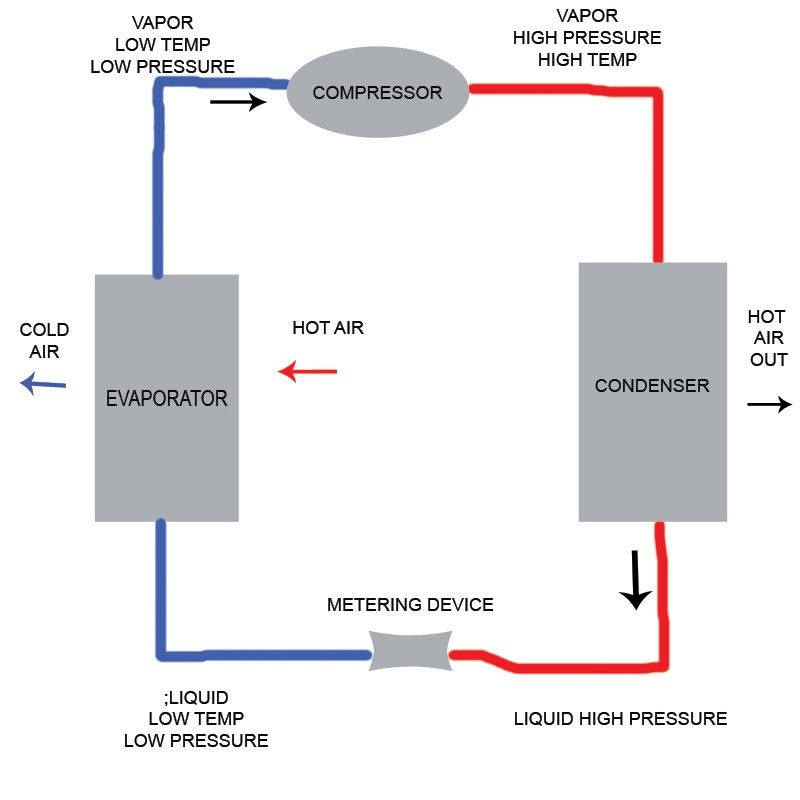

How It Works in HVAC Systems

Understanding how a liquid line solenoid valve works in HVAC systems helps clarify its importance in overall functionality. When activated by an electrical signal from the thermostat or control board, the solenoid coil engages and either opens or closes the valve accordingly; this action directly influences refrigerant flow rates within the system. By controlling this flow precisely, it ensures efficient cooling while preventing issues such as flooding—essentially answering questions like what does the liquid line service valve do? The interaction between these valves helps maintain stable operating conditions across various temperatures and loads.

The Main Function of a Solenoid Valve

Controlling Refrigerant Flow

The primary function of a liquid line solenoid valve is to control the flow of refrigerant through the HVAC system. By regulating this flow, the valve ensures that only the necessary amount of refrigerant enters the evaporator coil, which directly affects cooling efficiency. When asking What is a liquid line solenoid valve for?, one can see that its ability to manage refrigerant flow is vital in preventing flooding and ensuring that the system operates smoothly.

Moreover, accurate control over refrigerant flow minimizes energy consumption by preventing excess refrigerant from circulating through components that do not require it at any given time. This precise management not only enhances comfort levels within conditioned spaces but also prolongs equipment life by reducing wear and tear on critical components. In essence, controlling refrigerant flow is at the heart of what makes a liquid line solenoid valve indispensable in HVAC systems.

Ensuring Efficient Cooling

Efficient cooling is paramount in any HVAC setup, and this is where solenoid valves shine brightly. By regulating how much refrigerant flows into the evaporator coil, they help maintain ideal temperatures without overworking the compressor or other components. The question What does the liquid line service valve do? often arises here; while service valves allow for maintenance access, it's the liquid line solenoid valve that actively manages cooling during operation.

Furthermore, an efficient cooling process not only enhances comfort but also reduces energy consumption—an increasingly important factor as energy costs rise globally. When installed correctly (which brings us to “Where to install a liquid line solenoid valve?”), these valves can significantly improve overall system performance and reduce operational costs over time. Thus, ensuring efficient cooling becomes one of the main functions of a solenoid valve in any effective HVAC design.

Impact on System Reliability

The impact of a liquid line solenoid valve on system reliability cannot be overstated; it serves as a protective mechanism against potential failures within an HVAC system. By controlling refrigerant flow effectively and preventing issues such as flooding or excessive pressure buildup, these valves help maintain consistent operating conditions throughout various cycles of heating or cooling. This leads us back to understanding What is the main function of a solenoid valve?—to enhance reliability by safeguarding against common operational pitfalls.

Additionally, when paired with other components like service valves during maintenance operations (which brings us back to What does the liquid line service valve do?), they work together seamlessly to ensure longevity and dependability in performance across all seasons. With reliable operation comes peace of mind for users who depend on their HVAC systems for comfort year-round—making reliability one key aspect where investing in quality components pays off significantly.

Liquid Line Solenoid Valve Purpose

The liquid line solenoid valve plays a crucial role in HVAC systems, ensuring smooth operation and preventing potential issues. Understanding the liquid line solenoid valve purpose is essential for anyone involved in maintenance or installation. It ultimately contributes to the overall reliability and efficiency of the system.

Role in Preventing Liquid Flooding

One of the primary functions of a liquid line solenoid valve is to prevent liquid flooding in the evaporator coil. When refrigerant flows through the system, too much liquid can lead to inefficient cooling and even compressor damage. By regulating refrigerant flow, this valve ensures that only vapor enters the compressor, safeguarding it from potential harm.

In HVAC systems, controlling refrigerant flow is vital for optimal performance. Without proper regulation, issues like liquid flooding can arise, causing operational disruptions and costly repairs. Thus, knowing what is a liquid line solenoid valve for? helps technicians understand its critical role in maintaining system integrity.

Protecting Components from Damage

The importance of protecting components from damage cannot be overstated when discussing the liquid line solenoid valve purpose. This valve acts as a safeguard against conditions that might lead to excessive pressure or temperature fluctuations within the system. By preventing these fluctuations, it enhances component longevity and reduces maintenance costs.

In addition to protecting components like compressors and evaporators, this valve also helps maintain consistent cooling performance across various operating conditions. Understanding what does the liquid line service valve do? provides insight into how both valves work together to ensure reliability and efficiency within HVAC systems. Ultimately, a well-functioning solenoid valve contributes significantly to overall system health.

Enhancing Overall System Efficiency

Enhancing overall system efficiency is another vital aspect of what is the main function of a solenoid valve? The efficient control of refrigerant flow leads to better energy consumption and reduced operational costs for HVAC systems. This not only translates into savings for users but also aligns with growing environmental concerns regarding energy use.

Moreover, when you consider where to install a liquid line solenoid valve?, strategic placement can further optimize its effectiveness in enhancing system efficiency. Proper installation allows for quick response times during varying load conditions while ensuring that all components operate harmoniously together. As industries increasingly seek innovative solutions like those offered by ARCTIC, understanding these functions becomes paramount for future advancements in HVAC technology.

Where to Install a Liquid Line Solenoid Valve

When it comes to the liquid line solenoid valve purpose, proper installation is crucial for optimal performance in HVAC systems. Understanding where to install a liquid line solenoid valve can significantly enhance system efficiency and reliability. Let's explore the ideal locations, best practices for installation, and key considerations that will help you make the most of this essential component.

Ideal Locations in HVAC Systems

The ideal locations for installing a liquid line solenoid valve often include areas close to the compressor and evaporator coil. This placement allows for efficient control of refrigerant flow, directly addressing the question: what is a liquid line solenoid valve for? By positioning it strategically in these zones, you ensure that refrigerant can be effectively managed throughout the system, preventing issues like flooding and ensuring consistent cooling performance.

Additionally, placing the liquid line solenoid valve near service ports makes maintenance easier and more efficient. This proximity allows technicians quick access when they need to perform routine checks or repairs. Ultimately, understanding where to install a liquid line solenoid valve not only aids in functionality but also enhances overall system management.

Best Practices for Installation

When installing a liquid line solenoid valve, adhering to best practices is essential for achieving maximum efficiency. First and foremost, ensure that all connections are secure and leak-free; this will prevent refrigerant loss and maintain optimal pressure levels within the system. Remember that proper orientation matters too—installing the valve in accordance with manufacturer guidelines ensures it operates as intended.

Moreover, consider using vibration isolators during installation to reduce wear on components over time. This practice helps maintain longevity while also enhancing performance by minimizing disturbances caused by vibrations from other parts of the HVAC system. Following these best practices guarantees that your choice of where to install a liquid line solenoid valve aligns with its main function: controlling refrigerant flow efficiently.

Considerations for Optimal Performance

To achieve optimal performance from your liquid line solenoid valve, several considerations should be taken into account during installation. First off, assess environmental factors such as temperature fluctuations or exposure to corrosive elements; these can impact both functionality and lifespan of your valves over time. Selecting high-quality components designed specifically for your application will further improve reliability.

Another critical consideration involves ensuring adequate electrical connections are made—after all, what does the liquid line service valve do without proper power? Ensuring that wiring meets industry standards prevents malfunctions while promoting seamless operation within your HVAC system's framework. By keeping these factors in mind when determining where to install a liquid line solenoid valve, you're setting yourself up for success in maintaining an efficient cooling solution.

What Does the Liquid Line Service Valve Do?

When it comes to HVAC systems, understanding the liquid line service valve is crucial for effective maintenance and operation. This valve plays a significant role in managing refrigerant flow and ensuring that your system operates smoothly. So, what does the liquid line service valve do? Let’s dive into its function, differences from solenoid valves, and how it works in tandem with other components.

Function and Importance in Maintenance

The primary function of the liquid line service valve is to allow technicians to access the refrigerant circuit for maintenance purposes without affecting the overall system pressure. This access is vital during servicing tasks such as recharging refrigerant or performing leak checks. By enabling safe and efficient maintenance, this valve plays a pivotal role in prolonging equipment life and ensuring optimal performance—essentially safeguarding your investment in HVAC technology.

In terms of importance, regular maintenance facilitated by this valve can prevent costly breakdowns or inefficiencies that could arise if refrigerant levels are not properly managed. For instance, if a technician needs to check whether there’s adequate refrigerant flow or if any leaks are present, accessing through the liquid line service valve becomes indispensable. Its ability to isolate sections of the system allows for targeted repairs while minimizing disruption to overall operations.

Differences from Solenoid Valves

While both liquid line solenoid valves and service valves are integral components of HVAC systems, they serve distinctly different purposes. The liquid line solenoid valve purpose revolves around controlling refrigerant flow based on system demands—opening or closing automatically depending on operational conditions. In contrast, the liquid line service valve primarily provides access points for maintenance rather than actively regulating flow.

Another key difference lies in their operation: solenoid valves utilize an electromagnetic mechanism to open or close rapidly based on signals from the thermostat or control system; meanwhile, service valves are manually operated by technicians using specialized tools during servicing tasks. Understanding these differences can help clarify why both types of valves are essential for efficient HVAC functionality—one manages flow while the other facilitates upkeep.

Working Together in HVAC Systems

Liquid line solenoid valves and liquid line service valves complement each other within an HVAC setup by serving interconnected roles that ensure reliability and efficiency. The solenoid valve controls when refrigerant enters specific parts of the system based on real-time demands while ensuring that no excess fluid floods critical components—a crucial aspect of what is a liquid line solenoid valve for?

On the other hand, when it comes time for routine checks or repairs—what does the liquid line service valve do? It allows technicians easy access without needing extensive disassembly or risking contamination of refrigerants during servicing operations. Together, these two types of valves create a robust framework that enhances system performance while simplifying maintenance tasks—making them indispensable allies in keeping your HVAC running smoothly.

Conclusion

In summary, liquid line solenoid valves are essential components in HVAC systems, playing a crucial role in controlling refrigerant flow and ensuring efficient cooling. Their primary function revolves around preventing liquid flooding and protecting critical system components from damage. Understanding the liquid line solenoid valve purpose not only enhances system reliability but also boosts overall efficiency.

Key Takeaways on Solenoid Valves

What is a liquid line solenoid valve for? It's all about managing the refrigerant flow effectively, which directly impacts the performance of your HVAC system. The main function of a solenoid valve is to act as a gatekeeper, allowing or stopping the flow based on specific operational conditions, thereby ensuring that your cooling system works seamlessly when needed.

Importance of Installation Locations

Where to install a liquid line solenoid valve? The placement is vital for optimal performance; it should be positioned strategically to prevent issues such as flooding and ensure easy access for maintenance. Proper installation locations can significantly enhance the effectiveness of the solenoid valve, leading to improved energy efficiency and prolonged equipment life.

Future of HVAC Solutions with ARCTIC

As we look towards the future of HVAC solutions with ARCTIC, we see an exciting landscape filled with innovation and tailored solutions like custom cooling systems and compact chillers designed for various industries. With their focus on high-performance designs that meet specific customer needs, ARCTIC is paving the way for enhanced thermal management technologies that will redefine efficiency standards in HVAC applications. The continued evolution of these technologies ensures that understanding components like the liquid line service valve will remain crucial in maintaining optimal system performance.