Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

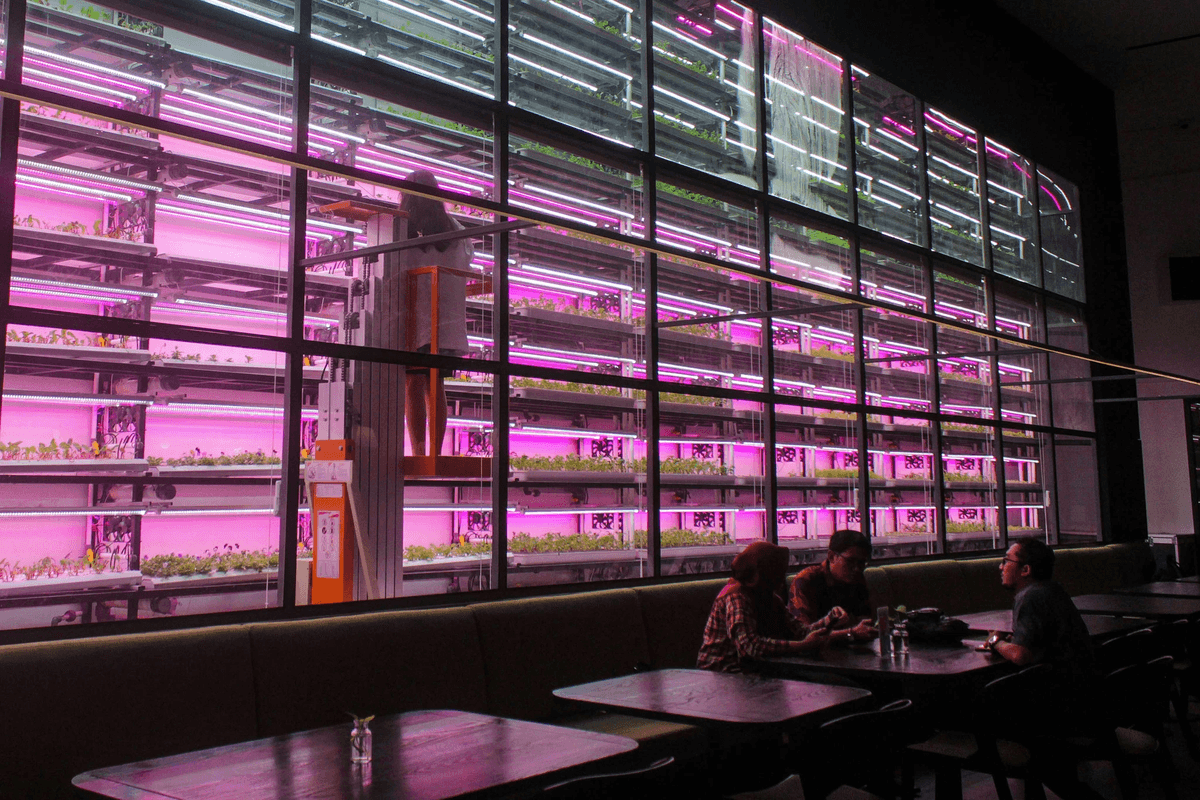

Indoor vertical farming is revolutionizing the way we think about food production, and at the heart of this innovative approach lies a crucial component: the chiller. Understanding indoor vertical farming chillers is essential for grasping how these systems contribute to efficient crop yields and sustainable practices. As we delve into the role of chillers in agriculture, we’ll uncover their significance in maintaining optimal growing conditions through advanced temperature control systems.

Understanding Indoor Vertical Farming Chilllers

So, what is an indoor vertical farming chiller? Essentially, it’s an air conditioning system tailored specifically for the unique needs of vertically stacked crops. These specialized air conditioning units are designed to manage temperature and humidity levels effectively, ensuring that plants thrive in a controlled environment regardless of external weather conditions.

The Role of Chilliers in Sustainable Agriculture

Chillers play a pivotal role in sustainable agriculture by enabling farmers to maximize crop yields while minimizing resource consumption. By utilizing efficient heating and AC technologies, these systems help maintain ideal growing conditions year-round without relying heavily on traditional agricultural methods that can be resource-intensive. In essence, they provide a balance between heat & air conditioner needs, promoting environmentally friendly practices in food production.

Insights into Temperature Control Systems

Temperature control systems are integral to indoor vertical farming operations; they ensure that crops receive consistent airflow and optimal temperatures for growth. Advanced HVAC servicing techniques allow farmers to monitor and adjust these systems remotely, enhancing efficiency and reducing energy waste. With innovations like ARCTIC’s miniature compressors leading the charge, the future of air conditioning solutions looks promising for those looking to harness the power of controlled environments in agriculture.

What is Indoor Vertical Farming Chiller

Indoor vertical farming chillers are specialized air conditioning systems designed to maintain optimal temperatures in controlled agricultural environments. These systems are essential for ensuring that crops receive the right conditions for growth, especially when traditional farming methods are not feasible. By utilizing advanced cooling technologies, indoor vertical farms can thrive even in urban settings or regions with challenging climates.

Defining Indoor Vertical Farming

Indoor vertical farming refers to the practice of growing crops in stacked layers within a controlled environment, often using hydroponics or aeroponics. This innovative method maximizes space and resource efficiency while minimizing land usage. Understanding what indoor vertical farming chiller systems do is crucial, as they play a significant role in regulating the temperature and humidity necessary for healthy plant growth.

The Need for Effective Cooling Solutions

The need for effective cooling solutions in indoor vertical farms cannot be overstated; without proper temperature control, plants may suffer from stress or fail to thrive altogether. Since these farms often operate under artificial lighting and high-density planting conditions, maintaining an ideal microclimate is vital to achieving optimal yields. Hence, investing in reliable air conditioning units specifically designed for agricultural use is essential for success.

Key Components of a Chiller System

A chiller system typically consists of several key components that work together to provide efficient cooling: evaporators, condensers, compressors, and expansion valves. These components function as part of an integrated air conditioning system that regulates temperature and humidity levels within the growing environment. Understanding how these parts interact can help farmers make informed decisions about their heating & ac needs and ensure that their HVAC servicing remains efficient over time.

How Chilliers Enhance Crop Yields

In the realm of indoor vertical farming, chillers play a crucial role in enhancing crop yields by providing optimal temperature regulation. The right air conditioning system ensures that plants thrive in a controlled environment, which is essential for maximizing growth potential. With efficient heating and AC solutions, farmers can create the perfect climate for their crops, leading to healthier plants and higher outputs.

Temperature Regulation for Optimal Growth

Temperature regulation is vital in indoor vertical farming, as different crops have specific requirements for growth. What is indoor vertical farming chiller? It’s a specialized cooling system designed to maintain these ideal temperatures consistently. By using advanced air conditioning units specifically tailored for agricultural settings, farmers can ensure that their plants receive the right amount of heat & air conditioner support to flourish.

Maintaining stable temperatures not only promotes plant health but also prevents stress that could lead to reduced yields. A well-implemented HVAC servicing strategy allows farmers to monitor and adjust temperature settings effectively, ensuring optimal conditions at all times. This attention to detail translates directly into improved crop quality and quantity.

The Impact of Controlled Environments

Controlled environments are one of the hallmarks of successful indoor vertical farming operations. By utilizing an effective chiller system, growers can manipulate factors such as humidity and temperature with precision—creating an ideal microclimate for crops. This level of control minimizes risks associated with external weather conditions and pests, allowing farmers to focus on producing high-quality produce year-round.

The integration of heating & AC systems further enhances this controlled environment by balancing temperature fluctuations that may occur during different times of the day or season. The ability to fine-tune these conditions leads to faster growth rates and more robust plants overall. In essence, creating a stable atmosphere through innovative cooling solutions sets successful farms apart from traditional agriculture.

Case Studies of Success in Vertical Farms

Various case studies have showcased how chillers contribute significantly to successful vertical farming ventures across the globe. For instance, one urban farm implemented ARCTIC's compact liquid chiller technology within their Micro-Farm™ setup; this collaboration resulted in remarkable improvements in both yield and energy efficiency. By optimizing their air conditioning system with ARCTIC’s innovations, they were able to produce fresh greens while minimizing environmental impact.

Another example highlights a hydroponic farm that utilized specialized air conditioning units designed for precise temperature control during critical growth stages of lettuce cultivation—leading to an impressive 30% increase in crop yield over traditional methods! These success stories underscore the importance of integrating advanced heating & AC technologies into modern agricultural practices.

As more farmers recognize what is indoor vertical farming chiller technology can do for them, we can expect continued advancements in sustainable agriculture practices fueled by innovation and efficiency.

Exploring Cooling Technologies

In the world of indoor vertical farming, the choice of cooling technology can make or break a harvest. Understanding the various air conditioning systems available is crucial for farmers looking to optimize their operations. With advancements in heating and AC solutions, growers are better equipped than ever to create ideal environments for their crops.

Different Types of Air Conditioning Systems

When it comes to indoor vertical farming chillers, there are several types of air conditioning systems that can be employed. From traditional split systems to more advanced ductless mini-split units, each option has its own set of benefits tailored for specific needs. Additionally, some farms opt for evaporative coolers or chilled beam systems that use water as a cooling medium, offering an energy-efficient alternative to conventional HVAC servicing.

The right air conditioning units not only regulate temperature but also manage humidity levels essential for plant health. Selecting an appropriate system will depend on factors such as farm size, crop type, and local climate conditions. Ultimately, the goal remains clear: achieve optimal growth conditions while minimizing energy consumption and operational costs.

Benefits of Miniature Compressors

One standout innovation in cooling technology is the miniature compressor, which has revolutionized how we approach indoor vertical farming chillers. These compact devices provide powerful cooling capabilities while taking up minimal space—perfect for farms with limited real estate. The efficiency of these compressors means they consume less energy compared to traditional models, making them ideal for farmers focused on sustainability.

Moreover, miniature compressors are often designed with advanced features that enhance their performance in diverse environments. This flexibility allows farmers to maintain consistent temperatures even during peak heat periods or fluctuations in external weather conditions. By integrating these innovative components into their heating and AC setups, growers can ensure maximum crop yields without breaking the bank on energy bills.

ARCTIC's Innovations in Chiller Solutions

ARCTIC stands at the forefront of miniature compressor innovation and has partnered with an American company to develop a liquid chiller solution specifically designed for their Micro-Farm™ initiative. This collaboration highlights how effective what is indoor vertical farming chiller technology can be when combined with cutting-edge engineering principles aimed at sustainability and efficiency. The compact liquid chiller from ARCTIC ensures that crops thrive under optimal conditions while minimizing environmental impact.

This innovative solution not only addresses temperature control but also supports broader agricultural goals by making locally-grown produce accessible even in challenging climates. With ARCTIC's commitment to reliability and eco-friendliness coupled with visionary approaches from American partners, this partnership aims to reshape agricultural practices worldwide—one micro-farm at a time. The future looks bright as these technologies continue to evolve alongside modern farming techniques.

Efficiency and Energy Consumption

In the realm of indoor vertical farming, efficiency and energy consumption are critical factors that can determine a farm's sustainability and profitability. Farmers are increasingly seeking energy-efficient solutions that minimize costs while maximizing crop yields. This section delves into how the right air conditioning systems and practices can significantly enhance operational efficiency.

Energy-Efficient Solutions for Farmers

Energy-efficient solutions for farmers often revolve around advanced air conditioning units designed specifically for indoor vertical farming environments. These units not only provide effective cooling but also utilize innovative technologies to reduce energy consumption, ensuring that heating and AC systems work harmoniously. By investing in such efficient systems, farmers can lower their carbon footprint while enjoying significant savings on utility bills.

Moreover, integrating smart technology into HVAC servicing allows farmers to monitor their energy usage in real-time, adjusting settings as necessary to optimize performance. The use of variable speed compressors in air conditioning systems is one example of how technology enhances efficiency by adjusting output based on actual cooling needs rather than running at full capacity continuously. This adaptability leads to a more sustainable operation overall.

As the demand for locally-sourced produce continues to rise, the importance of these energy-efficient solutions becomes even more apparent. Farmers who prioritize sustainability through effective heating and AC strategies not only contribute positively to the environment but also position themselves favorably in an increasingly eco-conscious market.

Balancing Heating and AC Needs

Balancing heating and AC needs is essential for maintaining optimal growing conditions in indoor vertical farms. With varying climate conditions outside, having a robust HVAC system that can adjust between heating and cooling as needed ensures crops thrive year-round. Effective temperature control directly impacts plant health, making it crucial for farmers to understand what is indoor vertical farming chiller technology can offer.

Farmers must consider both heat & air conditioner capabilities when selecting their equipment; this balance helps mitigate extreme temperature fluctuations that could stress plants or inhibit growth cycles. For instance, during colder months or in cooler climates, efficient heating solutions need to be implemented alongside cooling systems to create a stable environment conducive to plant development.

The challenge lies in choosing equipment that excels at both functions without incurring excessive energy costs—a task made easier with modern innovations in HVAC servicing techniques tailored for agricultural applications. As technology advances further, we may see even more integrated systems capable of seamlessly transitioning between heating & AC modes based on real-time environmental data.

The Future of HVAC Servicing in Agriculture

The future of HVAC servicing in agriculture looks promising as new technologies emerge aimed at enhancing efficiency across various farming operations, including indoor vertical farms utilizing chillers effectively. Innovations like ARCTIC’s miniature compressor solutions exemplify this trend by providing compact yet powerful options that fit perfectly into modern agricultural setups where space is at a premium.

As awareness grows about sustainable practices within agriculture, there will likely be an increased focus on developing advanced air conditioning systems tailored specifically for unique farming environments; these innovations will prioritize not just performance but also environmental impact reduction through lower emissions and energy use overall. Furthermore, ongoing advancements will allow farmers greater control over their climate management strategies through enhanced monitoring tools integrated with their heating & ac setups.

In conclusion, as we look toward the future of agriculture, embracing innovative HVAC servicing approaches will be key for farmers aiming to stay competitive while adhering to sustainable practices—after all, what is indoor vertical farming chiller technology if not a stepping stone towards greener methods? With continued investment in such technologies combined with smart management practices, the potential for improved crop yields alongside reduced resource consumption becomes increasingly attainable.

Choosing the Right Chiller

Selecting the right chiller for indoor vertical farming is a crucial decision that can significantly impact crop yields and energy consumption. The variety of air conditioning units available on the market can be overwhelming, but understanding key factors can simplify this process. From efficiency ratings to system compatibility, each element plays a vital role in ensuring optimal performance.

Factors to Consider When Selecting Air Conditioning Units

When determining what is indoor vertical farming chiller, one must consider several factors that influence its effectiveness. First and foremost, cooling capacity is essential; it should match the specific needs of your crops and growing environment. Additionally, energy efficiency ratings are critical—choosing an air conditioning system with high efficiency will reduce operational costs while supporting sustainable practices.

Another important factor is the system's ability to integrate with existing technologies in your facility, such as sensors for temperature control or automated systems for irrigation. Moreover, consider the noise levels of your chosen air conditioning units; quieter systems create a more conducive environment for both plants and workers alike. Lastly, think about future scalability; selecting a flexible heating & AC solution allows you to adapt as your farming operations grow.

Comparing Heat and Air Conditioner Options

When it comes to comparing heat & air conditioner options for indoor vertical farming chillers, it's essential to evaluate both functionality and cost-effectiveness. Traditional HVAC systems may provide adequate cooling but often fall short on energy efficiency compared to modern solutions like those offered by ARCTIC. Their miniature compressors are designed specifically for compact spaces, ensuring effective cooling without excessive energy consumption.

It’s also worth considering dual-function units that provide both heating and AC capabilities; these systems offer versatility throughout changing seasons while maintaining consistent temperature control. In addition, look into how each option affects humidity levels—an often-overlooked aspect that plays a significant role in plant health during growth cycles. Ultimately, balancing performance with cost will lead you to the best chiller solution tailored for your unique needs.

Importance of Maintenance for Longevity

Maintenance is paramount when discussing what is indoor vertical farming chiller because even the best systems require regular attention to perform optimally over time. Neglecting routine checks can lead to inefficiencies in heating & AC functions or even complete system failures—both costly scenarios for any farmer relying on controlled environments. Regular HVAC servicing not only extends equipment life but also ensures consistent performance across all operational aspects.

Cleaning filters regularly helps maintain airflow while checking refrigerant levels prevents any potential issues before they escalate into major repairs or replacements. Furthermore, staying proactive about maintenance schedules can save you significant amounts on energy bills by keeping your air conditioning units running efficiently year-round. By prioritizing upkeep within your facility, you’re investing not just in equipment longevity but also in sustainable agricultural practices overall.

Conclusion

In the ever-evolving world of agriculture, the integration of chillers into indoor vertical farming is proving to be a game-changer. These systems not only provide essential temperature control but also enhance crop yields by creating optimal growing conditions. As we look to the future, it's clear that what is indoor vertical farming chiller technology will play a crucial role in shaping sustainable agricultural practices.

The Future of Indoor Farming with Chilliers

The future of indoor farming is bright, especially with advancements in chiller technology. As urbanization continues to rise, the demand for locally grown produce will only increase, making air conditioning systems integral to indoor farms. By utilizing efficient air conditioning units and innovative heating and AC solutions, farmers can ensure that their crops thrive regardless of external weather conditions.

Moreover, as we embrace more compact and efficient cooling technologies like those from ARCTIC, the potential for scaling up these operations becomes even more viable. Their miniature compressors not only save space but also reduce energy consumption significantly. This means that what is indoor vertical farming chiller technology can be both effective and eco-friendly, paving the way for a greener future.

How Chilliers Support Sustainable Practices

Chillers are essential in supporting sustainable practices within agriculture by promoting resource efficiency and reducing waste. Effective temperature regulation through advanced air conditioning units helps minimize water usage while maximizing crop output. By ensuring that plants receive consistent conditions tailored to their needs, farmers can reduce reliance on chemical fertilizers and pesticides.

Additionally, innovations like ARCTIC's compact liquid chillers exemplify how modern technology can align with sustainability goals. These solutions not only enhance productivity but also help mitigate environmental impact by utilizing less energy compared to traditional systems. In this way, heating and AC solutions become allies in achieving a more sustainable agricultural landscape.

Final Thoughts on Agricultural Innovations

As we reflect on the role of chillers in indoor vertical farming, it's evident that innovations in HVAC servicing are vital for future developments in agriculture. The combination of effective temperature control with energy-efficient technologies creates an exciting opportunity for farmers worldwide to rethink traditional practices. What is indoor vertical farming chiller technology if not a testament to human ingenuity aimed at solving pressing food security challenges?

In conclusion, embracing these advancements ensures that our agricultural methods evolve alongside our growing population's needs while prioritizing sustainability and efficiency. With continued investment in research and development within this field, we can expect even greater breakthroughs that will redefine how we grow food sustainably for generations to come.