Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In today's fast-paced business environment, the efficiency and reliability of cold room refrigeration units are paramount. These systems play a crucial role in preserving perishable goods, making it essential to understand their intricacies. When considering what is a cold room in a refrigeration system, it's important to recognize how selecting the right equipment can significantly impact operational success.

Understanding Cold Room Refrigeration Units

Cold room refrigeration units are specialized systems designed to maintain specific temperature and humidity levels for various applications. From food storage to pharmaceutical preservation, these units ensure that products remain fresh and safe for extended periods. Understanding the mechanics behind Cold Room Refrigeration Systems allows businesses to make informed decisions about their cooling needs.

Importance of Choosing the Right Equipment

Choosing the right equipment for your cold room is not just about functionality; it’s about optimizing performance and cost-effectiveness over time. The wrong choice can lead to inefficiencies, increased energy costs, and even potential spoilage of valuable inventory. By asking questions like which refrigerant is used in cold rooms or what equipment is used in the cold room, you can tailor your setup for maximum effectiveness.

Benefits of Reliable Cold Room Systems

Reliable cold room systems offer numerous benefits that extend beyond mere temperature control. They enhance product quality by maintaining optimal conditions while also reducing waste through better preservation methods. Moreover, with advancements like Arctic Active Cooling's Top-Mounted Monoblock Refrigeration Unit, businesses can achieve unparalleled efficiency while adhering to energy efficiency goals—making these systems both economically and environmentally sound.

What is a Cold Room in a Refrigeration System?

Cold rooms are essential components of Cold Room Refrigeration Systems, designed to maintain specific temperature and humidity levels for various perishable goods. These specialized refrigeration units play a crucial role in preserving the quality and safety of products ranging from food items to pharmaceuticals. Understanding what a cold room is in a refrigeration system helps businesses make informed decisions about their cooling needs.

Definition and Purpose

A cold room is essentially a controlled environment that provides optimal storage conditions for temperature-sensitive items. Its primary purpose is to slow down the deterioration process of perishable goods by maintaining low temperatures, thereby extending shelf life and ensuring product safety. This makes cold rooms indispensable for industries like food service, pharmaceuticals, and agriculture, where product integrity is paramount.

Key Features of Cold Rooms

Cold room refrigeration units come with several key features that set them apart from standard refrigeration systems. They typically include advanced insulation materials to minimize energy loss and maintain stable internal temperatures, as well as precise temperature control mechanisms that ensure consistent conditions. Additionally, many modern systems are equipped with monitoring technology that allows users to track temperature fluctuations remotely—a game-changer for businesses relying on strict compliance standards.

Typical Applications

Cold rooms find their way into various sectors due to their versatility and reliability in preserving sensitive products. Common applications include storing fresh produce in supermarkets, maintaining pharmaceuticals at regulated temperatures in hospitals, and even housing delicate flowers in florists' shops—ensuring they stay vibrant longer. As businesses increasingly prioritize efficiency and sustainability, the demand for reliable cold room refrigeration systems continues to grow across multiple industries.

Which Refrigerant is Used in Cold Rooms?

When it comes to cold room refrigeration units, the choice of refrigerant is crucial for both performance and environmental impact. Understanding which refrigerants are available can help you make informed decisions about your Cold Room Refrigeration Systems. This section will delve into the types of refrigerants used, their environmental considerations, and the regulatory landscape surrounding them.

Types of Refrigerants Available

Cold rooms utilize various types of refrigerants, each with its unique properties and applications. Common options include hydrofluorocarbons (HFCs), hydrocarbons (HCs), and ammonia (NH3). HFCs are widely used due to their efficiency, but they have a high global warming potential; hydrocarbons offer a more eco-friendly alternative, while ammonia is preferred in industrial settings for its excellent thermodynamic properties.

Choosing the right refrigerant for your cold room refrigeration units can significantly affect energy consumption and operational costs. For instance, if you're looking at what equipment is used in the cold room, understanding the compatibility of specific refrigerants with those systems is vital. Ultimately, selecting an appropriate refrigerant will contribute to the overall effectiveness of your Cold Room Refrigeration Systems.

Environmental Impact Considerations

The environmental impact of refrigerants cannot be overlooked when discussing which refrigerant is used in cold rooms. Many traditional refrigerants contribute to ozone depletion or have high global warming potential (GWP). As businesses become more environmentally conscious, opting for low-GWP alternatives has become a priority.

This shift not only helps mitigate climate change but also aligns with increasing consumer demand for sustainable practices in industries that rely on cold storage solutions. In evaluating what are the requirements for a cold room, consider how your choice of refrigerant impacts energy efficiency and sustainability goals as well as compliance with evolving regulations.

Regulatory Compliance and Safety

Regulatory compliance plays a significant role in determining which refrigerant is suitable for use in cold rooms. Various international agreements like the Montreal Protocol aim to phase out substances that deplete the ozone layer while promoting safer alternatives. Familiarizing yourself with local laws regarding refrigeration systems ensures that you choose compliant options when setting up your cold room refrigeration units.

Safety also remains paramount; some refrigerants can be flammable or toxic if not handled correctly. Therefore, it's essential to ensure that any equipment used in the cold room meets safety standards while being compatible with your choice of refrigerant—this ties back into what equipment is used in the cold room and how it operates efficiently under varying conditions.

What Equipment is Used in the Cold Room?

Cold room refrigeration units are essential for maintaining optimal temperatures and conditions for various applications, from food storage to pharmaceuticals. Understanding the equipment used in cold rooms is crucial for ensuring efficiency and reliability. This section delves into the essential components, advanced options, and highlights a standout product that exemplifies excellence in cold room refrigeration systems.

Essential Components of Cold Room Systems

A well-designed cold room refrigeration system comprises several key components that work together to maintain the desired environment. The primary elements include compressors, condensers, evaporators, and insulation materials. Each component plays a vital role; for instance, compressors circulate refrigerants while condensers release heat outside the cold room, ensuring optimal performance and energy efficiency.

In addition to these core elements, temperature control systems and monitoring devices are critical for maintaining consistent conditions inside the cold room. These systems help monitor humidity levels and temperatures to prevent spoilage or degradation of stored products. Properly integrating these essential components will ensure that your cold room operates smoothly and meets industry standards.

Advanced Options for Enhanced Performance

For businesses looking to optimize their cold room refrigeration systems further, advanced options can significantly enhance performance. Upgraded insulation materials can improve energy efficiency by minimizing heat transfer between the interior of the cold room and external environments. Additionally, smart technology solutions allow for real-time monitoring and control of temperature settings via mobile devices or centralized systems.

Furthermore, incorporating energy-efficient compressors can lead to substantial cost savings over time while reducing environmental impact—a critical consideration when evaluating which refrigerant is used in cold rooms. By investing in advanced features such as variable speed drives or automated defrosting systems, businesses can achieve better temperature stability while extending equipment lifespan.

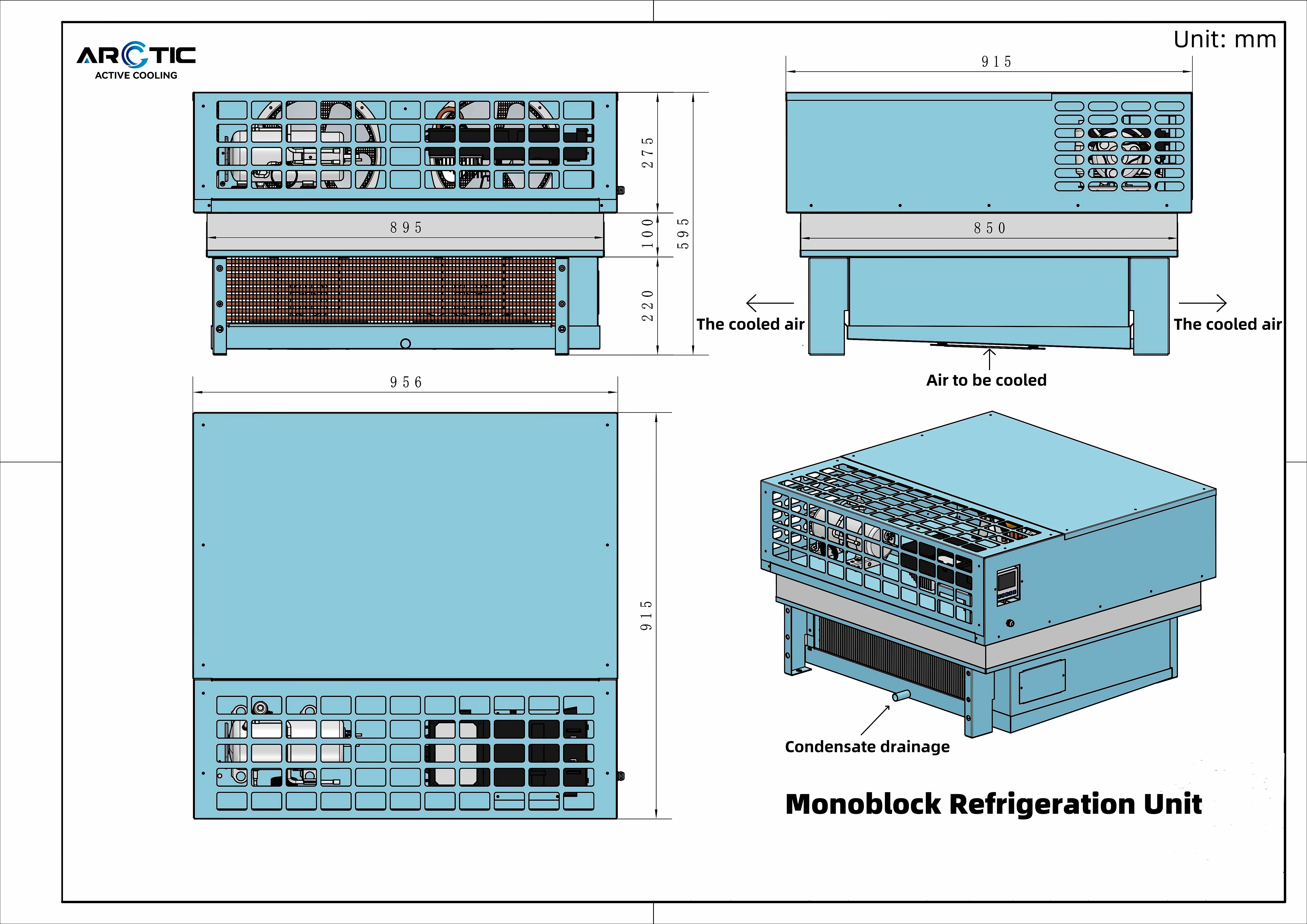

Highlight on Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit

When it comes to exceptional performance in cold room refrigeration units, Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit stands out as a top-tier choice. This innovative unit is designed specifically for commercial refrigerators, freezers, and small to mid-sized cold rooms—perfectly aligning with modern cooling applications' demands. With its all-in-one design, it offers unparalleled convenience without compromising on efficiency or reliability.

One notable application of Arctic's Monoblock Refrigeration Units includes maintaining optimal humidity levels for storing fresh flowers at florists or wholesale flower markets—a task that requires precision cooling solutions! By choosing this unit as part of your Cold Room Refrigeration Systems setup, you’re not just investing in equipment; you're opting for sustainability along with superior performance tailored to meet your specific needs.

What are the Requirements for a Cold Room?

When considering the implementation of cold room refrigeration units, several critical requirements must be addressed to ensure optimal performance and efficiency. Understanding these requirements can significantly impact the effectiveness of your cold room refrigeration systems. From space considerations to energy efficiency goals, each aspect plays a vital role in maintaining the ideal environment for your stored products.

Space and Layout Considerations

The space allocated for a cold room is not just about fitting in equipment; it’s about creating an efficient workflow. When planning your cold room layout, consider access points for deliveries and personnel, ensuring that movement within the space is smooth and unobstructed. Additionally, strategic placement of cold room refrigeration units will maximize cooling efficiency while allowing for adequate air circulation.

Adequate insulation is another key factor in space considerations; without it, you may end up with higher energy costs and inconsistent temperatures. The dimensions of your cold room should also align with regulatory standards relevant to what is being stored, whether that's perishables or pharmaceuticals. Ultimately, a well-thought-out layout contributes not only to functionality but also enhances overall operational efficiency.

Temperature and Humidity Control Standards

Temperature control is paramount in any discussion about what is a cold room in a refrigeration system? Each type of product has specific temperature requirements that must be maintained consistently to prevent spoilage or degradation. Cold rooms often need to operate within strict temperature ranges—typically from -20°C to 10°C—depending on their applications.

Humidity control also plays an essential role alongside temperature management; improper humidity levels can lead to moisture buildup or drying out products prematurely. Utilizing advanced monitoring systems can help maintain these conditions effectively while providing real-time data for adjustments as necessary. By adhering to established temperature and humidity control standards, businesses can ensure that their cold room refrigeration systems operate optimally.

Energy Efficiency Goals

Energy efficiency should be at the forefront when establishing what are the requirements for a cold room? Not only does this contribute positively to environmental sustainability, but it also significantly impacts operating costs over time. Investing in high-efficiency equipment like Arctic Active Cooling's Top-Mounted Monoblock Refrigeration Unit can yield substantial savings while maintaining superior performance.

These energy-efficient units are designed specifically for commercial refrigerators and small to mid-sized cold rooms, ensuring optimal operation without excessive energy consumption. Setting clear energy efficiency goals allows businesses not only to comply with regulations but also enhances their overall bottom line by reducing utility expenses over time. Striving for efficient operations ultimately leads you toward sustainable practices that benefit both your business and the planet.

What is the Right Equipment for a Cold Room?

Choosing the right equipment for cold room refrigeration units is crucial for maintaining optimal conditions. A well-designed cold room refrigeration system not only ensures the preservation of perishable goods but also contributes to operational efficiency. Understanding your specific requirements will guide you in selecting the most suitable equipment tailored to your needs.

Assessing Your Specific Needs

When assessing your specific needs for a cold room, consider factors such as size, temperature requirements, and the types of products you intend to store. Different applications may require varying levels of cooling efficiency; thus, it's essential to determine what is a cold room in a refrigeration system that fits your business model. For instance, if you’re storing sensitive items like pharmaceuticals or fresh flowers, maintaining precise temperature and humidity levels becomes paramount.

Additionally, evaluate the layout of your space and how it will accommodate various cold room refrigeration units. This includes understanding airflow dynamics and ensuring there’s enough space for maintenance access without compromising storage capacity. By thoroughly assessing these factors upfront, you'll make more informed decisions regarding which equipment best meets your operational demands.

Top Brands and Models Available

The market offers a plethora of options when it comes to choosing cold room refrigeration systems from reputable brands known for their reliability and performance. Notable names include Arctic Active Cooling, whose Top-Mounted Monoblock Refrigeration Unit stands out due to its innovative design tailored for commercial refrigerators and freezers alike. This advanced cooling solution is engineered specifically for small to mid-sized cold rooms, making it an ideal choice for businesses focused on performance and sustainability.

Other reliable brands include Carrier and Trane, both offering robust systems that cater to diverse cooling needs across various industries. When evaluating which refrigerant is used in cold rooms offered by these brands, ensure that they comply with environmental regulations while providing efficient cooling solutions tailored to your requirements.

Long-Term Maintenance and Support

Selecting the right equipment goes beyond just initial purchase considerations; long-term maintenance and support are equally important aspects of owning cold room refrigeration units. Regular servicing helps ensure that your Cold Room Refrigeration Systems operate at peak efficiency while extending their lifespan significantly. Establishing a relationship with a trusted service provider can alleviate potential headaches down the line when issues arise.

Moreover, many manufacturers offer extended warranties or service packages that include routine check-ups as part of their offerings—something worth considering during your selection process! Being proactive about maintenance not only saves costs but also ensures consistent performance from your chosen equipment over time.

Conclusion

In summary, understanding cold room refrigeration units is crucial for any business reliant on maintaining specific temperature and humidity levels. Cold Room Refrigeration Systems are not just about keeping things chilly; they play a vital role in preserving the quality of perishable goods, ensuring compliance with health standards, and enhancing operational efficiency. By grasping key concepts such as what a cold room in a refrigeration system entails, the types of refrigerants used, and the essential equipment required, businesses can make informed decisions that positively impact their bottom line.

Key Takeaways on Cold Room Systems

Cold rooms serve as specialized environments designed to store temperature-sensitive products across various industries. The choice of refrigerant is paramount; it must balance efficiency with environmental considerations while adhering to safety regulations. Additionally, understanding what equipment is used in the cold room—like advanced options such as the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit—can significantly enhance performance and reliability.

Final Thoughts on Equipment Selection

Selecting the right equipment for a cold room is not merely about functionality; it's about aligning that functionality with your specific needs and goals. Businesses should assess their requirements carefully by considering factors like space layout, temperature control standards, and energy efficiency objectives. Investing in high-quality Cold Room Refrigeration Systems ensures longevity and reduces maintenance costs over time.

Make Informed Decisions for Your Business

With all this information at your disposal, it's time to take action! Evaluate your current setup against the requirements for a cold room to identify any gaps or areas for improvement. By choosing reliable cold room refrigeration units that meet both performance expectations and regulatory standards, you can ensure your business thrives in an increasingly competitive environment.