Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In an era where energy efficiency and sustainability are paramount, understanding the water loop system becomes increasingly essential. These systems play a crucial role in various applications, providing effective cooling solutions that minimize waste and enhance operational efficiency. As businesses seek to optimize their resources, the importance of efficient cooling systems cannot be overstated.

Understanding the Water Loop System

So, what is a water loop system? At its core, it is a network designed to circulate water for heating or cooling purposes across multiple units or spaces. This innovative approach not only streamlines temperature regulation but also reduces energy consumption by recycling water through a closed-loop mechanism.

Importance of Efficient Cooling Systems

Efficient cooling systems are vital for maintaining optimal conditions in commercial and industrial settings. They help prevent product spoilage and equipment overheating, ensuring smooth operations across various sectors. By leveraging technologies such as water loops, businesses can significantly reduce their carbon footprint while maximizing performance.

Benefits of Closed-Loop Water Systems

What is a closed-loop water system? It’s a specialized form of the water loop system that recirculates cooled or heated water without discharge into the environment. The benefits of closed-loop systems include lower operational costs, improved temperature control, and enhanced sustainability—making them an attractive option for businesses looking to modernize their cooling strategies.

What is a Water Loop System?

Understanding the water loop system is crucial for businesses looking to optimize their cooling processes. So, what is a water loop system? Essentially, it’s an efficient method of circulating water to transfer heat away from various applications, ensuring that spaces remain at optimal temperatures. This system is designed to enhance energy efficiency while reducing operational costs, making it an attractive option for many industries.

Definition and Key Components

A water loop system consists of several key components that work together seamlessly. At its core, you have the water source—typically a chiller or cooling tower—that supplies chilled water throughout the system. Other essential elements include pumps for circulation, piping systems for distribution, and heat exchangers that facilitate effective temperature control in various applications. Understanding these components helps clarify what are water loops for and how they function in real-world scenarios.

How It Works in Different Applications

So how does this all come together in practice? The beauty of a loop water distribution system lies in its versatility across different applications—from commercial refrigeration to industrial processes. For instance, in cold storage facilities like those using Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit, the water loop efficiently maintains optimal humidity and temperature levels for perishable goods such as fresh flowers. By circulating chilled water through these units, businesses can achieve unparalleled efficiency while ensuring product integrity.

Comparing with Traditional Cooling Methods

When comparing a water closed loop system with traditional cooling methods, the advantages become evident quickly. Traditional systems often rely on refrigerants that can be less efficient and more harmful to the environment compared to the eco-friendly approach of a closed-loop setup. Moreover, while conventional air conditioning systems might struggle with temperature fluctuations or require excessive maintenance, a well-designed water loop system offers consistent performance and reduced energy consumption—making it a smart investment for any business looking to modernize their cooling strategy.

Advantages of Water Loops for Businesses

Water loop systems have become increasingly popular in various industries, thanks to their numerous advantages. The efficiency of a water loop system can lead to significant cost savings, improved temperature control, and eco-friendly solutions that benefit both businesses and the environment. Understanding what a water loop system can offer is essential for companies looking to optimize their operations.

Cost-Effectiveness and Energy Savings

One of the most compelling reasons businesses are turning to water loops is their cost-effectiveness. A well-designed loop water distribution system can significantly reduce energy consumption compared to traditional cooling methods, leading to lower utility bills over time. Additionally, by utilizing a closed-loop water system, companies can minimize maintenance costs associated with frequent repairs and replacements often seen in older systems.

Investing in advanced technologies like waterloop refrigeration technology enhances these savings even further. These systems efficiently recycle water used for cooling processes, allowing businesses to maximize their resources while minimizing waste. In essence, what are water loops for? They serve as an investment that pays off through substantial energy savings and reduced operational costs.

Enhanced Temperature Control

Temperature control is crucial for many industries, particularly those dealing with sensitive products such as pharmaceuticals or perishable goods. Water loop systems provide precise temperature regulation, ensuring optimal conditions are maintained consistently throughout the cooling cycle. This level of control not only enhances product quality but also extends shelf life—an invaluable advantage for businesses reliant on maintaining freshness.

What is a closed-loop water system? It allows for continuous circulation without introducing external contaminants or fluctuations in temperature. This stability is vital in applications like Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit, which excels at maintaining ideal humidity and temperature levels for fresh flowers in florists and wholesale markets.

Eco-Friendly Solutions

In today's environmentally conscious market, businesses must adopt sustainable practices that align with consumer expectations. Water loops provide eco-friendly solutions by significantly reducing the amount of freshwater consumed during cooling processes compared to traditional methods—what is a loop water distribution system if not an innovative approach toward sustainability? By recycling existing resources rather than relying on new supplies, companies contribute positively to environmental conservation efforts.

Furthermore, implementing a closed-loop water system decreases the likelihood of harmful runoff or waste entering local ecosystems—a critical consideration for many industries today. As more organizations recognize the importance of sustainability, integrating technologies like waterloop refrigeration technology becomes not just beneficial but essential for staying competitive while also being responsible stewards of our planet's resources.

The Functionality of a Loop Water Distribution System

A loop water distribution system is designed to maximize efficiency in resource allocation, particularly in cooling applications. By utilizing a closed-loop mechanism, this system continuously recirculates water, which minimizes waste and enhances performance. Understanding how a water loop system operates can help businesses make informed decisions about their cooling needs.

How Water Loops Distribute Resources Efficiently

So, what is a water loop system? It's a sophisticated method that circulates water through various components to maintain optimal temperatures across different areas. This efficient circulation reduces the energy needed for cooling by leveraging the constant flow of chilled water instead of relying on standalone units that operate independently.

Water loops are particularly advantageous because they provide uniform temperature control throughout the facility, ensuring that every corner receives adequate cooling without overheating or cold spots. By integrating sensors and automated controls, these systems can adjust flow rates based on real-time conditions, making them highly responsive and energy-efficient. Ultimately, the efficiency of a loop water distribution system leads to significant cost savings for businesses while minimizing their environmental impact.

Applications in Industrial Settings

What are water loops for? They serve various industrial applications where temperature regulation is critical—think food processing plants, data centers, and manufacturing facilities. In these environments, maintaining precise temperatures is essential not only for product quality but also for operational efficiency.

For instance, in food processing settings where perishable items are handled, having a reliable closed-loop water system ensures that products stay fresh throughout the production line. Additionally, industries like pharmaceuticals rely heavily on consistent temperature control to meet strict regulatory standards; here too, loop systems shine by providing stability and reliability under fluctuating loads. As more industries recognize the benefits of advanced cooling technologies like those found in waterloop refrigeration technology, we expect to see further adoption across diverse sectors.

Case Studies of Successful Implementations

To illustrate the effectiveness of loop water systems further, let’s explore some case studies highlighting successful implementations. One notable example involves Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit used in commercial refrigeration settings such as cold rooms and freezers. This innovative unit exemplifies how efficient design can enhance performance while maintaining optimal humidity levels—critical for storing fresh flowers in florists and wholesale flower markets.

Another case study involves an industrial manufacturing facility that integrated a closed-loop water system into its production process. By doing so, they were able to reduce energy consumption by over 30% while improving overall operational efficiency—a win-win scenario! These examples showcase not just what is a closed-loop water system but also how effective it can be when applied correctly within various industries.

Exploring Water Closed Loop Systems

Water closed loop systems have become increasingly important in various industries, particularly for their efficiency and sustainability. But what exactly is a closed-loop water system? This system recycles water within a defined loop, minimizing waste and optimizing resource use. Essentially, it operates by circulating water through a series of pipes and equipment, allowing for effective temperature regulation and energy savings.

What is a Closed-Loop Water System?

A closed-loop water system refers to a setup where water circulates continuously through a network without being discharged into the environment. This method is particularly advantageous in applications like cooling and heating, where maintaining consistent temperatures is crucial. In essence, the question What is a water closed loop system? can be answered by noting its ability to efficiently manage thermal loads while conserving resources.

The components of this system typically include pumps, heat exchangers, and storage tanks—all working harmoniously to ensure that the same volume of water can be reused multiple times. By utilizing this approach, businesses can significantly reduce their reliance on fresh water sources while also decreasing operational costs associated with traditional cooling methods. The efficiency of such systems positions them as an attractive alternative for industries seeking sustainable solutions.

Benefits in Commercial Refrigeration

One standout application of this technology is seen in Arctic Active Cooling's Top-Mounted Monoblock Refrigeration Unit. This innovative unit not only maintains optimal humidity but also ensures precise temperature management for cold rooms storing sensitive products like fresh flowers in florists or wholesale markets. With its compact design and efficient operation, it exemplifies how integrating a loop water distribution system can lead to substantial improvements in energy savings.

Moreover, these systems contribute positively towards environmental sustainability by minimizing waste discharge into local ecosystems while maximizing resource utilization within facilities. As businesses increasingly aim for eco-friendly practices, the benefits of adopting closed-loop systems become more apparent.

Integration with Advanced Technologies

The integration of advanced technologies with closed-loop systems has revolutionized how industries approach cooling solutions today. By leveraging smart sensors and IoT devices within the framework of what is a loop water distribution system?, companies can monitor performance metrics in real-time—allowing immediate adjustments based on demand fluctuations or external conditions.

This synergy between technology and traditional methods enhances overall efficiency while providing valuable data insights that guide future decision-making processes regarding maintenance schedules or upgrades needed within the infrastructure itself. Furthermore, innovations such as variable-speed pumps enable even greater customization tailored specifically to each facility’s unique requirements—ensuring optimal performance at all times.

As we look toward the future of refrigeration technology—especially with advancements like Waterloop refrigeration technology—the potential applications seem limitless! From reducing carbon footprints to improving profitability through energy savings; embracing these integrated solutions will undoubtedly position businesses favorably amid rising environmental concerns.

Real-World Applications of Water Loop Systems

Water loop systems are increasingly being adopted across various industries due to their efficiency and versatility. By leveraging the principles of a loop water distribution system, businesses can optimize their cooling processes while reducing operational costs. This section explores real-world applications that highlight the effectiveness of these systems in practical scenarios.

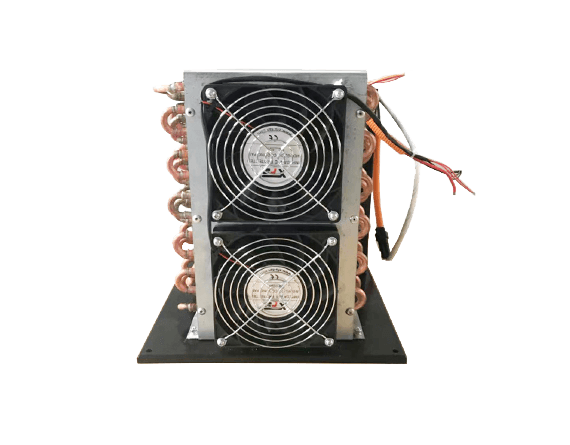

Arctic Active Cooling’s Monoblock Refrigeration Units

Arctic Active Cooling has revolutionized commercial refrigeration with their Top-Mounted Monoblock Refrigeration Unit, a prime example of water loop system technology in action. This innovative unit is designed for optimal performance in cold rooms, freezers, and commercial refrigerators, ensuring that businesses maintain precise temperature control while minimizing energy consumption. The integration of waterloop refrigeration technology enhances reliability and efficiency, making it an ideal choice for industries that require strict temperature management.

What is a water loop system? In this context, it refers to a closed-loop mechanism that circulates chilled water through the refrigeration unit to absorb heat efficiently. This process not only improves energy savings but also supports sustainability initiatives by reducing greenhouse gas emissions associated with traditional cooling methods. With Arctic's monoblock units maintaining optimal humidity and temperature for sensitive products like fresh flowers in florists and wholesale markets, it's clear why many businesses are making the switch.

Effective Use in Cold Rooms and More

Cold rooms benefit immensely from implementing a water closed loop system, as they provide consistent temperatures essential for preserving perishable goods. The ability to maintain specific climate conditions allows businesses to store everything from pharmaceuticals to food products without compromising quality or safety. Additionally, what are water loops for? They serve as an efficient means of distributing cooling resources throughout the space while minimizing energy wastage.

The versatility of a loop water distribution system means it can be tailored to various applications beyond cold storage; think data centers or manufacturing facilities where precise temperature control is crucial. By utilizing advanced technologies integrated into these systems, companies can achieve higher operational efficiency while significantly cutting costs related to energy consumption and maintenance. When paired with effective monitoring solutions, these systems ensure optimal performance across diverse environments.

Achieving Optimal Performance in Various Industries

Industries ranging from healthcare to food service are discovering how beneficial a water loop system can be for their operations. By employing what is a closed-loop water system?, companies can recycle chilled water efficiently within their facility instead of relying solely on external sources or traditional air-based cooling methods. This not only leads to significant cost savings but also promotes sustainability through reduced environmental impact.

In sectors such as hospitality or food processing where temperature control is paramount, implementing a loop water distribution system provides enhanced reliability and consistency in product quality. Moreover, case studies have shown that organizations using advanced technologies alongside these systems report improved productivity levels due to minimized downtime caused by equipment failures or inefficient cooling processes. As more businesses recognize the advantages offered by this innovative approach, we anticipate an even greater shift towards adopting efficient cooling solutions like Arctic Active Cooling’s monoblock refrigeration units.

Conclusion

In conclusion, the water loop system represents a significant advancement in cooling technology that can revolutionize how businesses manage their temperature control needs. Understanding what is a water loop system is crucial for organizations looking to enhance efficiency while reducing costs. As we explored, these systems not only provide effective cooling solutions but also support eco-friendly practices that are increasingly important in today’s business landscape.

Key Takeaways on Water Loop Systems

Key takeaways about water loops include their ability to efficiently distribute resources across various applications, which makes them ideal for industries that require precise temperature management. What are water loops for? They serve multiple purposes such as improving energy efficiency, reducing operational costs, and enhancing overall performance in both commercial and industrial settings. Additionally, understanding what is a closed-loop water system can help businesses appreciate how closed-loop systems minimize waste and maximize resource use.

The Future of Water Recycling Technologies

The future of water recycling technologies looks promising as more businesses adopt innovative solutions like the loop water distribution system to meet sustainability goals. With increasing pressure to reduce environmental footprints, companies are turning to advanced systems that recycle and reuse resources effectively—this includes what is a closed-loop water system designed specifically for efficiency and minimal waste. As industries continue to evolve, integrating technologies like Waterloop refrigeration technology will be essential in achieving both operational excellence and environmental responsibility.

Why Businesses Should Consider Water Loops

Businesses should consider implementing a water loop system not just for its cost-effectiveness but also for its ability to provide enhanced temperature control tailored to specific needs. What is a loop water distribution system? It’s an intelligent solution that optimizes resource allocation while maintaining quality standards across various applications—from food storage facilities using Arctic Active Cooling's Monoblock Refrigeration Units to industrial manufacturing plants requiring stringent climate controls. Ultimately, investing in these systems positions businesses as leaders in innovation while contributing positively towards sustainability efforts.