Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the bustling world of food service and retail, commercial refrigeration rack systems play a pivotal role in keeping products fresh and safe. These systems are designed to optimize temperature control, making them essential for businesses that rely on refrigeration. Understanding the intricacies of refrigeration racks not only helps in making informed choices but also enhances operational efficiency.

Understanding Commercial Refrigeration Rack Systems

Commercial refrigeration rack systems consist of multiple components working together to maintain optimal temperatures for various applications. Typically, they feature a centralized system that distributes refrigerant to multiple display cases or storage units, ensuring consistent cooling throughout. By grasping what these systems entail, businesses can appreciate their importance in preserving product quality and minimizing energy consumption.

Benefits of Modern Refrigeration Racks

Modern refrigeration racks offer numerous advantages over traditional systems, including enhanced energy efficiency and reduced operational costs. With advanced technology and design improvements, these racks can significantly lower electricity bills while maintaining superior cooling performance. Additionally, the modular nature of contemporary refrigeration racks allows for easy scalability and customization to meet specific business needs.

Key Features to Look For

When selecting a commercial refrigeration rack system, it's crucial to consider several key features that can impact overall performance and longevity. Look for systems with high-efficiency compressors, reliable temperature controls, and robust insulation materials that improve energy savings. Furthermore, understanding questions like What are the three types of refrigeration systems? or Where do commercial refrigeration rack systems get their name? can provide valuable context for making an informed decision.

What Are the Three Types of Refrigeration Systems?

Distinguishing Between Types

The three primary types of refrigeration systems are vapor-compression, absorption, and thermoelectric. Vapor-compression systems are the most commonly used in commercial refrigeration rack systems due to their reliability and efficiency. Absorption systems, on the other hand, utilize heat sources instead of electricity, making them suitable for specific applications where energy costs are a concern. Lastly, thermoelectric systems use solid-state technology to provide cooling without moving parts, offering a quieter alternative but generally at a higher cost per cooling unit.

Applications of Each System

Vapor-compression refrigeration racks are widely employed in supermarkets and cold storage facilities because they can efficiently handle large volumes of perishable goods. Absorption refrigeration is often found in locations where waste heat is available or where electricity supply is unreliable; think remote areas or industrial settings that can leverage waste heat from other processes. Thermoelectric units may be less common but find their niche in small-scale applications such as portable coolers or specialized equipment requiring precise temperature control.

Impact on Efficiency and Cost

The choice between these three types of refrigeration systems ultimately affects both operational efficiency and overall costs for businesses utilizing commercial refrigeration rack systems. Vapor-compression models typically offer lower operating costs due to their high efficiency but may require more maintenance over time compared to absorption units that can have higher initial costs yet lower energy expenses in specific scenarios. Understanding these distinctions helps businesses evaluate what is most suitable for their needs while maximizing performance and minimizing expenses.

Where Do Commercial Refrigeration Rack Systems Get Their Name?

The term commercial refrigeration rack systems has a rich history that reflects the evolution of refrigeration technology itself. Initially, these systems were designed to house multiple refrigeration units in one compact space, resembling a rack. This design not only optimized the use of space but also enhanced efficiency, leading to the adoption of the name rack systems.

Historical Context

The origins of commercial refrigeration rack systems can be traced back to the early 20th century when refrigeration technology began to take off. The need for efficient food preservation in restaurants and supermarkets drove innovation, resulting in the development of centralized cooling solutions. These early systems utilized large compressors and condensers that were often mounted on racks, paving the way for what we now recognize as modern refrigeration racks.

Evolution of Rack Systems

Over time, commercial refrigeration rack systems have evolved significantly due to technological advancements and changing market demands. Initially bulky and inefficient, today's refrigeration racks are designed with energy efficiency in mind, utilizing advanced refrigerants and modular components. The integration of smart technologies has further transformed these systems into intelligent units capable of optimizing performance based on real-time data.

Modern Usage

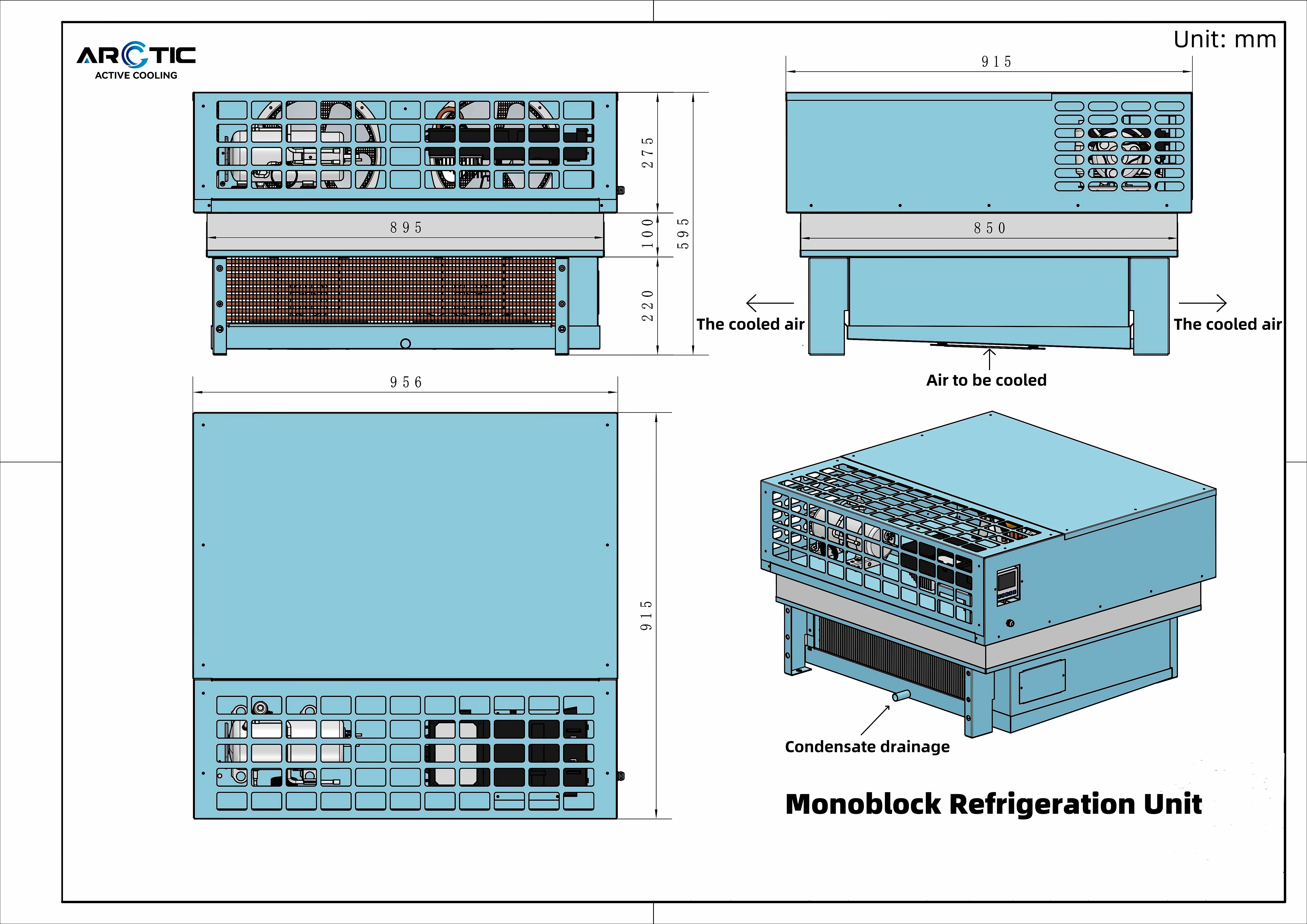

In contemporary settings, commercial refrigeration rack systems play a crucial role across various industries such as food service, grocery stores, and cold storage facilities. These systems are celebrated for their ability to maintain consistent temperatures while minimizing energy consumption—an essential factor given rising operational costs. Furthermore, innovative solutions like Arctic Active Cooling's Mini Water Chiller exemplify how modern designs continue to push boundaries by offering integrated parts that streamline installation and enhance user experience.

What Is a Rack System in Refrigeration?

When discussing commercial refrigeration rack systems, it's essential to understand what constitutes a rack system. A rack system in refrigeration is essentially a centralized setup that uses multiple compressors to serve several refrigerated cases or walk-in coolers simultaneously. This not only maximizes efficiency but also provides a reliable solution for various commercial applications, making it an integral part of modern refrigeration technology.

Defining Rack Systems

Rack systems are designed to optimize the cooling process by utilizing multiple compressors that work together to maintain desired temperatures across different units. These systems are particularly popular in large-scale operations like supermarkets and warehouses where consistent temperature control is crucial. When someone asks, What is a rack system in refrigeration? they’re essentially referring to this sophisticated network of components that ensures efficient cooling.

Components of a Rack System

A typical commercial refrigeration rack system consists of several key components: compressors, condensers, evaporators, and controls. The compressors are responsible for circulating refrigerant throughout the system, while condensers and evaporators manage heat exchange processes effectively. Additionally, advanced control systems allow operators to monitor performance and make real-time adjustments—ensuring optimal operation across all refrigerated areas.

Advantages Over Traditional Systems

One significant advantage of using commercial refrigeration rack systems over traditional setups is their improved energy efficiency. By consolidating multiple cooling units into one centralized system, businesses can reduce energy consumption and lower operational costs significantly. Moreover, these racks often require less maintenance due to their robust design and integrated components—providing long-term reliability that traditional systems may lack.

The Most Common Refrigerants in Commercial Refrigeration

In the world of commercial refrigeration rack systems, the choice of refrigerant plays a crucial role in both efficiency and environmental impact. Understanding what is the most common refrigerant in commercial refrigeration can help businesses make informed decisions about their cooling solutions. This section delves into the top refrigerants, their environmental considerations, and emerging trends.

Top Refrigerants Explained

When it comes to commercial refrigeration rack systems, several refrigerants stand out due to their performance and reliability. R134a has long been a favorite for its efficiency in medium-temperature applications, while R404A is often used for low-temperature scenarios due to its excellent cooling capacity. However, newer alternatives like R448A and R449A are gaining traction as they offer lower global warming potential (GWP) without compromising on performance—making them attractive options for modern refrigeration racks.

Environmental Impact Considerations

The environmental impact of refrigerants cannot be overlooked, especially with increasing regulations aimed at reducing greenhouse gas emissions. Many traditional refrigerants have high GWP levels that contribute significantly to climate change when released into the atmosphere. As businesses seek sustainable solutions within their commercial refrigeration rack systems, opting for low-GWP alternatives is becoming not just a trend but a necessity for compliance and corporate responsibility.

Trends in Refrigerant Use

The landscape of refrigerant use is evolving rapidly as industries adapt to new technologies and regulations. One notable trend is the shift towards natural refrigerants like ammonia and CO2, which boast minimal environmental impact compared to synthetic options. Additionally, Arctic Active Cooling's innovative Mini Water Chiller exemplifies this shift by integrating advanced refrigeration parts designed for optimal efficiency and performance—perfectly suited for OEM and ODM projects looking to innovate within their cooling systems.

The Role of Arctic Active Cooling in the Industry

In the ever-evolving landscape of commercial refrigeration rack systems, Arctic Active Cooling stands out with its innovative solutions that cater to diverse needs. Their Mini Water Chiller is a prime example of how modern technology can enhance efficiency and performance in refrigeration racks. This compact system is designed to meet the demands of various applications while ensuring optimal cooling capabilities.

Innovative Mini Water Chillers

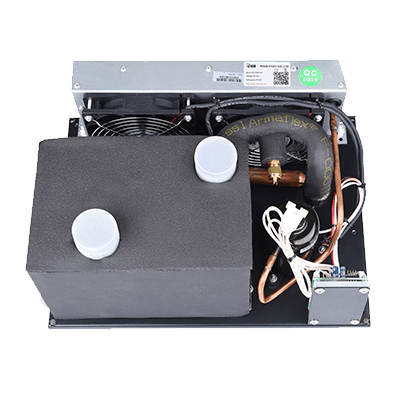

Arctic Active Cooling's Mini Water Chiller is a game-changer in the world of commercial refrigeration rack systems. Featuring a high-efficient refrigeration mini compressor using R134a coolant, this system integrates all essential components into one sleek unit, including the smallest condenser and plate evaporator. Such sophisticated design not only simplifies installation but also provides end users with cutting-edge micro cooling solutions tailored for their specific needs.

The Mini Water Chiller’s appeal lies in its adaptability for customers who prefer modular cooling subsystems to integrate with their machines or equipment. By allowing connections to their control boards, users can fine-tune compressor speeds for optimal performance based on individual requirements. This level of customization makes it an attractive option for those exploring what are the three types of refrigeration systems available today.

Benefits of Integrated Refrigeration Parts

One significant advantage of Arctic Active Cooling's approach is the integration of refrigeration parts within their systems, which streamlines functionality and reduces installation time for commercial refrigeration rack systems. With all components working seamlessly together, users experience fewer operational hiccups and enhanced reliability compared to traditional setups that often require separate installations for each component.

Moreover, this integrated design helps minimize space requirements, making it ideal for businesses where every square foot counts—especially when considering what is a rack system in refrigeration? The ease of assembly and maintenance translates into cost savings over time while ensuring that businesses can focus on maximizing efficiency rather than troubleshooting complex setups.

Applications for OEM and ODM Projects

Arctic Active Cooling's innovative solutions extend beyond standard applications; they are particularly well-suited for Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) projects seeking reliable cooling options within their product lines. By offering customizable mini water chillers that fit seamlessly into existing designs, they empower manufacturers to enhance their offerings without compromising quality or performance.

These applications highlight how commercial refrigeration rack systems can be tailored to meet specific industry demands—from food preservation to industrial processes requiring precise temperature control. As companies increasingly seek sustainable options amid discussions about what is the most common refrigerant in commercial refrigeration today, Arctic Active Cooling’s commitment to evolving technology positions them as leaders in integrating eco-friendly solutions into modern designs.

Conclusion

In wrapping up our exploration of commercial refrigeration rack systems, it's clear that these systems are not just a passing trend but a vital part of modern refrigeration technology. As we look ahead, the landscape of commercial refrigeration will continue to evolve, driven by innovation and efficiency demands. Understanding the nuances of refrigeration racks and their applications will be crucial for businesses aiming to stay competitive.

The Future of Commercial Refrigeration

The future of commercial refrigeration is leaning heavily towards sustainability and efficiency, with advancements in technology paving the way for smarter solutions. As businesses seek to reduce their carbon footprints, the importance of understanding what are the three types of refrigeration systems? becomes paramount; each type offers unique benefits tailored to different needs. Moreover, innovations like Arctic Active Cooling's Mini Water Chiller exemplify how integrated systems can enhance performance while minimizing environmental impact.

Choosing the Right Rack System

Selecting the right rack system is a decision that can significantly influence operational efficiency and cost-effectiveness in your business. When considering options, it’s essential to ask yourself: What is a rack system in refrigeration? This understanding helps you identify components that best suit your needs while maximizing space utilization and energy savings. Additionally, familiarity with where do commercial refrigeration rack systems get their name? provides historical context that can inform your choices today.

Maximizing Efficiency in Your Operations

Maximizing efficiency in your operations involves more than just selecting high-quality equipment; it requires an ongoing commitment to best practices and continuous improvement. Understanding what is the most common refrigerant in commercial refrigeration allows you to make informed decisions about refrigerant management and environmental responsibility. By integrating advanced technologies like Arctic Active Cooling’s Mini Water Chiller into your setup, you can enhance operational performance while ensuring compliance with evolving regulations.