Introduction

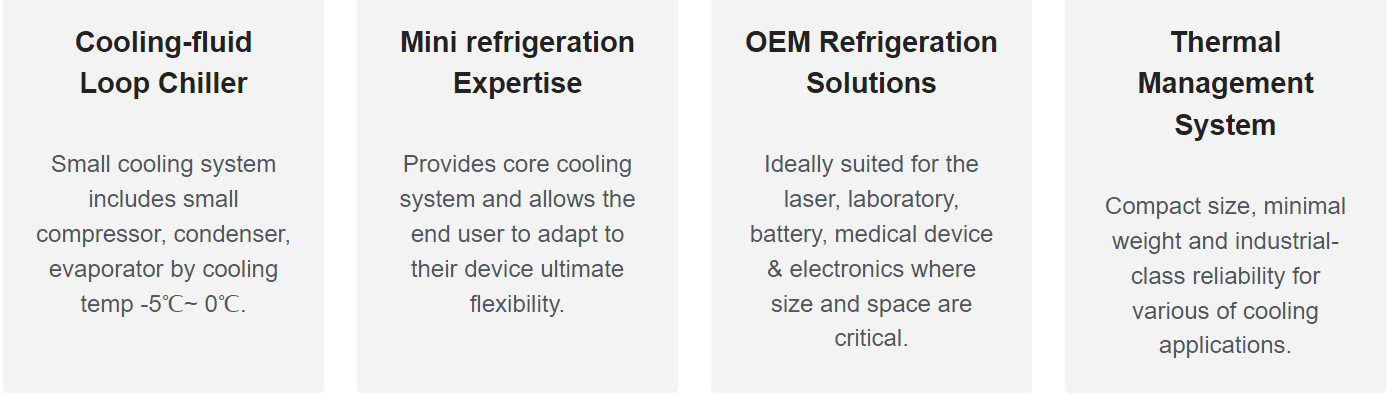

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

The Importance of Custom Cold Rooms

Custom cold rooms are vital for preserving perishable goods, ensuring quality control, and extending shelf life in sectors ranging from food service to pharmaceuticals. These specialized spaces provide the perfect environment for temperature-sensitive items, reducing waste and maximizing profitability. When you think about how much it costs to build a cool room, consider not just the initial investment but also the long-term benefits of maintaining product integrity.

Choosing the Right Storage Solution

Selecting the right storage solution involves evaluating your specific needs against available options in the market. Whether you're wondering about freezer rooms versus cold rooms or trying to figure out how do you design a cold room effectively, understanding your requirements will guide your choice. Making an informed decision ensures that you invest wisely in custom cold rooms that cater specifically to your operational demands.

Key Considerations for Cold Room Design

Designing an effective cold room is no small feat; it requires careful planning and consideration of multiple factors such as space optimization and climate control systems. The difference between a freezer room and a cold room lies not only in temperature settings but also in their intended use cases—knowing these distinctions helps streamline your design process. It's essential to prioritize features like temperature regulation, humidity control, and accessibility when embarking on this journey into custom cold rooms.

Understanding Custom Cold Rooms

Custom cold rooms are specially designed storage spaces that cater to specific temperature and humidity requirements for various products. Unlike standard refrigeration solutions, these rooms are tailored to meet the unique needs of businesses, ensuring optimal preservation of perishable goods. This customization not only enhances product longevity but also improves operational efficiency.

What Constitutes a Custom Cold Room?

A custom cold room is defined by its ability to be tailored in size, temperature range, and humidity levels according to the specific requirements of the stored items. Whether it’s for pharmaceuticals, food products, or sensitive materials, these rooms can be designed with precise specifications in mind. The question How do you design a cold room? often arises; the answer lies in understanding the needs of your inventory and integrating appropriate insulation and cooling technologies.

Applications Across Different Industries

Custom cold rooms find applications across a variety of industries including food processing, pharmaceuticals, laboratories, and even floral arrangements. In the food industry, they ensure that perishables like meat and dairy are stored at optimal temperatures to prevent spoilage. Similarly, in pharmaceuticals, maintaining strict temperature control is crucial for preserving the efficacy of medications—demonstrating just how versatile these custom cold rooms can be.

Benefits of Tailored Cooling Solutions

The benefits of tailored cooling solutions extend beyond mere temperature control; they include cost savings and improved product quality over time. Businesses often ask How much does it cost to set up a cold room? While initial investments may vary based on size and technology used, long-term savings through energy efficiency can significantly offset those costs. Additionally, custom cold rooms provide peace of mind by ensuring that valuable inventory is kept in optimal conditions—ultimately elevating business operations.

Cost Factors for Setting Up Cold Rooms

Setting up custom cold rooms can be a significant investment for any business, but understanding the cost factors involved is crucial to making informed decisions. The overall expense can vary widely based on several elements, including size, design complexity, and specific requirements of the cold room. So, how much does it cost to set up a cold room? This question often arises in discussions about tailored cooling solutions.

How Much Does It Cost to Set Up a Cold Room?

The cost of establishing custom cold rooms typically ranges from several thousand to tens of thousands of dollars. Factors such as insulation quality, cooling technology, and additional features like shelving or monitoring systems will influence the final price tag. On average, businesses often find themselves asking: how much does it cost to build a cool room? Understanding these variables can help you budget effectively.

When considering custom cold rooms, it's essential to factor in both initial setup costs and ongoing operational expenses. While the upfront investment may seem daunting, remember that tailored solutions can lead to increased efficiency and reduced spoilage over time. Ultimately, weighing these costs against potential benefits will guide your decision-making process.

Breakdown of Materials and Labor Expenses

To get a clearer picture of what goes into setting up custom cold rooms, let’s break down materials and labor expenses. Key components include high-quality insulation panels, refrigeration units (like Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit), flooring designed for low temperatures, and necessary electrical wiring. Each of these elements contributes significantly to both functionality and durability.

Labor costs also play an important role in the total expenditure when designing your cold room. Skilled technicians are needed for installation and setup; their expertise ensures that everything runs smoothly from day one. Remember that investing in quality labor can save you headaches later on—after all, how do you design a cold room without professional help?

Long-term Savings Through Energy Efficiency

One major advantage of investing in custom cold rooms is the long-term savings achieved through energy efficiency measures. Modern refrigeration technologies minimize energy consumption while maximizing cooling performance—a win-win for your bottom line! By opting for advanced solutions like Arctic Active Cooling's innovative systems, businesses can enjoy lower utility bills over time.

Moreover, well-designed custom cold rooms reduce spoilage rates by maintaining optimal temperature conditions for stored goods—this translates into better product quality and fewer losses due to waste. As businesses increasingly focus on sustainability practices alongside profitability, energy-efficient designs become even more appealing options worth considering.

In conclusion, while setting up custom cold rooms requires thoughtful budgeting around initial costs and ongoing expenses—especially when asking how much does it cost to set up a cold room—the potential long-term savings make them worthwhile investments for many industries.

Designing Your Cold Room: Essential Steps

Designing a custom cold room may seem like a daunting task, but it can be straightforward with the right approach. It begins with understanding your specific needs, including the types of products you’ll store and their ideal storage conditions. Additionally, considering how much it costs to build a cool room will help you make informed decisions throughout the design process.

How Do You Design a Cold Room?

To design a cold room effectively, start by assessing your space and determining the dimensions required for your storage needs. Consider factors such as insulation materials, door sizes, and shelving options that best suit your inventory. Understanding how much does it cost to set up a cold room will guide you in selecting features that balance functionality with budget constraints.

Once you've outlined the basic specifications, it's crucial to incorporate cooling systems that align with your requirements. This includes selecting between various refrigeration options like Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit for optimal performance and energy efficiency. By focusing on these elements during the design phase, you'll create a custom cold room tailored to enhance productivity while maintaining temperature integrity.

Maximizing Space and Accessibility

Maximizing space in your custom cold rooms is essential for efficient operations and easy access to stored items. Begin by evaluating shelving layouts and considering vertical storage solutions that utilize every inch of available space without compromising accessibility. Implementing wide aisles can also facilitate movement within the cold room, allowing staff easy access to products without hassle.

Additionally, incorporating modular designs can provide flexibility as business needs change over time; this approach allows for quick adaptations without extensive renovations or additional costs. When thinking about how much does it cost to set up a cold room, remember that an efficient layout can save both time and money in daily operations by reducing retrieval times and minimizing waste from expired goods.

Lastly, ensure that all areas of the custom cold rooms are easily navigable for both employees and equipment like forklifts or pallet jacks if necessary. Accessibility not only promotes safety but also enhances overall workflow efficiency—key factors when evaluating long-term investments in cooling solutions.

Importance of Temperature and Humidity Control

Temperature and humidity control are critical components in designing effective custom cold rooms; they directly impact product quality and shelf life. Implementing reliable monitoring systems ensures consistent temperature ranges suitable for different types of products—be it perishable foods or pharmaceuticals—which significantly reduces spoilage risks over time.

Moreover, understanding what is the difference between a freezer room and a cold room is essential when setting these controls; freezer rooms operate at lower temperatures than standard cold rooms designed for refrigeration purposes alone. By carefully calibrating these environmental factors based on specific inventory requirements, businesses can optimize their storage conditions while ensuring compliance with industry standards.

Investing in advanced technology such as Arctic Active Cooling’s innovative units further enhances temperature stability through precise control mechanisms designed specifically for commercial applications. With proper attention given to temperature and humidity management during design phases, businesses will reap long-term benefits from reduced waste costs while maintaining high-quality standards across their product offerings.

Types of Cold Rooms: Understanding the Options

When it comes to cold storage solutions, understanding the differences between various types of cold rooms is crucial for making informed decisions. Custom cold rooms can be tailored to meet specific needs, whether for temperature-sensitive goods or bulk storage. However, distinguishing between freezer rooms and standard cold rooms is essential for optimizing your cooling strategy.

Freezer Rooms vs. Cold Rooms

The primary difference between a freezer room and a cold room lies in their intended temperature ranges. Freezer rooms are designed to maintain sub-zero temperatures, ideal for preserving frozen foods or pharmaceuticals that require extreme cooling conditions. In contrast, standard cold rooms operate at higher temperatures, typically ranging from 32°F to 55°F (0°C to 13°C), making them suitable for fresh produce, dairy products, and other perishable items.

When considering how much it costs to set up a cold room versus a freezer room, one must account for the additional refrigeration power required for lower temperatures in freezer installations. This can lead to higher energy consumption and operational costs over time. Understanding these distinctions helps businesses decide which custom cold rooms fit their needs best.

When to Choose Freezer Rooms

Choosing a freezer room becomes essential when dealing with products that need long-term preservation at low temperatures. If you’re storing ice cream, frozen meats, or vaccines requiring consistent freezing conditions, then investing in a freezer room is non-negotiable. Additionally, if your business model revolves around high turnover of frozen goods or compliance with strict health regulations regarding food safety, opting for a dedicated freezer space is wise.

It's also worth noting that while initial setup costs may be higher—prompting questions like “How much does it cost to build a cool room?”—the investment pays off by extending product shelf life and reducing spoilage rates significantly. Thus understanding when to choose freezer rooms could save businesses both money and headaches down the line.

Unique Features of Cold Rooms

Custom cold rooms come packed with unique features tailored specifically for diverse applications across various industries. These spaces often include advanced temperature control systems that allow precise adjustments based on the specific requirements of the items stored within them. Furthermore, humidity control mechanisms ensure that delicate products like fruits and vegetables retain their quality without wilting or spoiling prematurely.

Another standout feature is the flexibility in design; businesses can customize layouts according to available space while maximizing efficiency—an aspect crucial when pondering how do you design a cold room? Moreover, modern advancements like Arctic Active Cooling's Top-Mounted Monoblock Refrigeration Units enhance performance by providing reliable cooling solutions that adapt seamlessly into custom setups.

Understanding these unique features helps businesses leverage custom cold rooms effectively as part of their operations while addressing questions about costs and efficiencies along the way.

Advanced Cooling Solutions for Efficiency

In the realm of custom cold rooms, efficiency is key to maintaining optimal storage conditions while keeping operational costs in check. Advanced cooling solutions have emerged as vital components in achieving these goals, particularly as businesses seek to enhance their refrigeration capabilities. This section will explore the innovative options available, focusing on Arctic Active Cooling units and their benefits.

Overview of Arctic Active Cooling Units

Arctic Active Cooling units are designed with cutting-edge technology tailored specifically for custom cold rooms and commercial refrigeration needs. These units provide a reliable and efficient solution for various cooling applications, catering to businesses that require precise temperature control. With their compact design and robust performance, they are perfect for those asking, How much does it cost to set up a cold room? since they offer significant long-term savings through energy efficiency.

The unique design of Arctic Active Cooling units allows them to fit seamlessly into existing setups or new installations without compromising space or accessibility. By integrating advanced features into a single unit, these systems simplify the installation process and reduce labor costs associated with setting up complex cooling systems. Therefore, when considering how much it costs to build a cool room, investing in an Arctic unit could prove beneficial both financially and operationally.

Benefits of Top-Mounted Monoblock Refrigeration

Top-mounted monoblock refrigeration systems represent one of the most effective cooling solutions for custom cold rooms today. These self-contained units combine all necessary components—compressors, condensers, and evaporators—into one compact package that can be easily installed on top of the cold room structure. This not only saves valuable floor space but also enhances overall system performance by minimizing refrigerant line lengths.

One major advantage is energy efficiency; top-mounted monoblock refrigeration minimizes energy consumption while maintaining consistent temperatures within your custom cold rooms. Businesses often inquire about how much it costs to set up a cold room; however, with this type of advanced cooling solution, you may find that your long-term savings outweigh initial expenditures due to reduced energy bills. Additionally, these systems require less maintenance compared to traditional setups because they are designed for durability and reliability.

Enhancing Performance with Technology

The integration of technology into custom cold rooms has transformed how businesses manage their refrigeration needs. Smart sensors and IoT connectivity allow real-time monitoring of temperature and humidity levels within your cool storage environment—a critical factor when discussing how do you design a cold room? With such technology at your fingertips, you can ensure that products remain fresh while optimizing energy consumption.

Moreover, advanced monitoring systems provide alerts when conditions deviate from preset parameters—helping prevent spoilage and waste in both freezer rooms and standard cold rooms alike. This proactive approach not only enhances product quality but also reduces operational risks associated with improper storage conditions—an essential consideration when evaluating what is the difference between a freezer room and a cold room? Ultimately, leveraging technology can lead to smarter decisions regarding inventory management while elevating overall business performance.

Conclusion

In a world where precision and adaptability are paramount, custom cold rooms stand out as essential assets for various industries. The future of these tailored solutions looks bright, with advancements in technology driving efficiency and sustainability. As businesses continue to seek ways to improve their operations, investing in custom cold rooms will likely become a standard practice rather than an exception.

The Future of Custom Cold Rooms

The evolution of custom cold rooms is being shaped by innovations that prioritize energy efficiency and operational flexibility. With options like Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit, businesses can expect enhanced performance while keeping costs manageable. As we look ahead, the integration of smart technology will further revolutionize how we design and operate these cooling solutions.

Making Informed Decisions on Costs

When considering how much it costs to set up a cold room or build a cool room, it's crucial to factor in both initial investments and long-term savings. Understanding the breakdown of materials and labor expenses can demystify the process, enabling better financial planning for your business. Remember that while upfront costs may seem daunting, energy-efficient designs often lead to significant savings over time.

Elevating Business Operations with Cold Storage Solutions

Custom cold rooms are not just about maintaining temperature; they play a pivotal role in enhancing overall business operations. By answering questions like What is the difference between a freezer room and a cold room? you can make informed decisions that align with your specific needs. Ultimately, investing in tailored cooling solutions equips businesses to meet market demands while ensuring product integrity.