Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the realm of food storage and preservation, cold room refrigeration systems play a pivotal role. These specialized setups are essential for maintaining optimal temperatures for perishable goods across various industries, from foodservice to pharmaceuticals. Understanding what a cold room refrigeration system entails is crucial for businesses aiming to enhance their operational efficiency and product quality.

Understanding Cold Room Refrigeration Systems

Cold room refrigeration systems are designed to create controlled environments that keep products at specific temperatures, ensuring freshness and safety. Essentially, they consist of insulated spaces equipped with powerful cooling units that regulate internal conditions. By utilizing advanced technologies, these systems can efficiently manage temperature fluctuations and maintain the integrity of stored items.

Importance of Efficient Refrigeration Solutions

The significance of efficient refrigeration solutions cannot be overstated, particularly in sectors where temperature control is critical. Businesses rely on these systems not only to preserve their products but also to minimize waste and reduce operational costs. An effective cold room refrigeration system can lead to substantial savings while ensuring compliance with health regulations.

Key Features of Walk-In Cold Rooms

Walk-in cold rooms offer unique advantages over traditional refrigeration methods, making them an ideal choice for many establishments. They provide ample space for storage while maintaining consistent temperatures throughout the area, thanks to superior insulation and advanced cooling technologies. Additionally, features such as customizable shelving and easy access make walk-in cold rooms convenient for daily operations.

What is Cold Room Refrigeration System?

Cold room refrigeration systems are integral to maintaining optimal conditions for perishable goods across various industries. These specialized systems ensure that temperature-sensitive items, such as food products and pharmaceuticals, are stored at consistent temperatures to prolong their shelf life and maintain quality. Understanding what cold room refrigeration entails can help businesses make informed decisions about their cooling needs.

Definition and Functionality

So, what is cold room refrigeration system? At its core, it refers to a controlled environment designed specifically for the storage of temperature-sensitive materials. These systems utilize powerful refrigeration units to maintain low temperatures, often below 0°C (32°F), which prevents spoilage and degradation of products stored inside.

The functionality of a cold room refrigeration system revolves around its ability to regulate temperature and humidity levels effectively. By employing advanced insulation techniques and reliable refrigerants, these systems can efficiently manage the internal climate, ensuring that the stored items remain fresh and safe for consumption or use. This makes cold rooms an essential component in various sectors where product integrity is paramount.

Common Applications in Various Industries

Cold room refrigeration finds applications across numerous industries due to its versatility and effectiveness in preserving goods. In the food industry, restaurants, supermarkets, and warehouses rely on these systems to store meat, dairy products, fruits, vegetables, and frozen foods at safe temperatures. Similarly, pharmaceutical companies utilize cold rooms for storing vaccines and sensitive medications that require strict temperature control.

Additionally, floral shops benefit from cold room refrigeration by keeping flowers fresh longer during transport or display. The agricultural sector also employs these systems for storing produce before distribution or processing. With such diverse applications, it's clear that understanding how cold room refrigeration works can significantly impact operational efficiency across multiple fields.

Advantages of Cold Room Refrigeration

There are several advantages associated with using a cold room refrigeration system that make them indispensable for businesses dealing with perishables. Firstly, they provide consistent temperature control which is crucial for preventing spoilage—this directly translates into reduced waste and increased profitability over time. Secondly, improved product quality leads to enhanced customer satisfaction; when customers receive fresher products, they're more likely to return.

Moreover, modern cold room solutions often come equipped with energy-efficient technologies that minimize operational costs while maximizing performance—a win-win situation! Businesses can also customize their setups based on specific needs by selecting appropriate sizes and configurations tailored to their inventory requirements. Ultimately, investing in effective cold room refrigeration solutions not only safeguards your products but also boosts your bottom line.

Which Refrigerant is Best for a Cold Room?

Overview of Popular Refrigerants

There are several popular refrigerants used in cold room refrigeration systems, each with its unique characteristics. Hydrofluorocarbons (HFCs) like R-134a and R-404A have been widely adopted due to their efficiency in heat transfer and relatively low toxicity. However, natural refrigerants like ammonia (R-717) and carbon dioxide (R-744) are gaining traction because they offer excellent thermodynamic properties and lower global warming potential.

In addition to HFCs and natural refrigerants, some businesses are exploring hydrocarbon options such as propane (R-290) for smaller systems due to their high efficiency and minimal environmental impact. While these alternatives may require specific handling procedures, they provide effective solutions for various applications within cold room refrigeration systems. Ultimately, choosing which refrigerant is best for a cold room depends on factors like application type, budget constraints, and environmental goals.

Environmental Considerations

Environmental considerations play a crucial role when determining which refrigerant is best for a cold room. Many traditional HFCs are being phased out globally due to their high global warming potential (GWP). As regulations tighten around greenhouse gas emissions, businesses must consider eco-friendly options that comply with both local laws and international agreements.

Natural refrigerants such as ammonia or carbon dioxide present compelling alternatives because they have negligible GWP compared to synthetic options. However, safety must also be considered; ammonia can be hazardous if not handled correctly while carbon dioxide requires higher operating pressures that may not suit all applications within the realm of what is cold room refrigeration system?

Efficiency and Performance Factors

Efficiency and performance factors are critical when selecting a refrigerant for your cold room refrigeration needs. The ideal refrigerant should facilitate optimal heat exchange while ensuring minimal energy consumption—this translates into lower operational costs over time. Additionally, the boiling point of the chosen refrigerant affects how well it performs at different temperatures; thus it’s essential to match this characteristic with your specific cooling requirements.

Another important aspect is how well the refrigerant works with existing equipment or new installations like the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit: Advanced Cooling for Cold Rooms. This innovative unit offers superior performance by utilizing suitable refrigerants tailored to modern cooling demands while ensuring reliability in small to mid-sized applications.

Ultimately, achieving maximum efficiency hinges on understanding these variables as you navigate through which refrigerant is best for a cold room tailored specifically to your business needs.

Will a Refrigerator Work in a Cold Room?

When considering whether a conventional refrigerator can operate effectively in a cold room, one must first understand the unique conditions of such environments. Cold room refrigeration systems are designed to maintain specific temperatures that can be significantly lower than typical household settings. This raises questions about the functionality and efficiency of standard refrigerators when faced with these cooler climates.

Evaluating Conventional Refrigerators

Conventional refrigerators are built to work optimally within a certain temperature range, usually around 32°F to 40°F (0°C to 4°C). However, cold rooms often operate at much lower temperatures, sometimes dipping below freezing, which can hinder the performance of these appliances. In such situations, you might find that your fridge struggles to maintain its internal temperature or even freezes food items intended for storage.

Moreover, when evaluating conventional refrigerators for use in cold rooms, it's essential to consider their energy consumption and compressor functionality. Standard models may not be equipped with the necessary insulation or components designed for low-temperature environments. Thus, while they may technically work, their efficiency and reliability could be compromised.

Limitations and Challenges

One of the primary limitations of using conventional refrigerators in cold rooms is their inability to adapt to fluctuating external temperatures effectively. These units often rely on ambient warmth to function correctly; thus, when placed in an environment that's already cold, they may cycle on and off excessively or fail altogether. Additionally, frost buildup can become an issue as moisture condenses inside the fridge due to temperature differences.

Another challenge is related to energy consumption; using non-specialized equipment in such conditions can lead to increased operational costs over time due to inefficiency. Businesses relying on cold room refrigeration need consistent performance without unexpected spikes in energy bills or equipment failure. Therefore, it’s critical that companies assess whether conventional refrigerators truly meet their cooling needs before making any investments.

Recommended Solutions for Cold Environments

For businesses looking for reliable solutions tailored specifically for cold environments, specialized refrigeration units should be prioritized over traditional models. The Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit is an excellent example of advanced cooling technology suited for commercial applications like walk-in cold rooms and freezers. Designed with efficiency and sustainability in mind, this innovative unit ensures optimal performance even under challenging conditions.

In addition to choosing specialized refrigeration systems like Arctic Active Cooling's offerings, proper insulation and layout design play crucial roles in maintaining ideal temperatures within a cold room setting. Investing in high-quality insulation materials will further enhance your system's efficiency by minimizing heat transfer from outside sources while allowing your chosen refrigeration unit—whether it’s an Arctic model or another—to perform at its best.

By understanding what constitutes effective cold room refrigeration systems and recognizing the limitations of conventional fridges within these spaces, businesses can make informed decisions that lead not only to operational success but also long-term cost savings.

Cold Room Design Considerations

Designing a cold room refrigeration system requires careful planning to ensure optimal performance and efficiency. From insulation to equipment selection, every detail matters in creating an environment that meets specific cooling needs. This section will delve into essential considerations for effective cold room design.

Insulation and Temperature Control

Insulation is the backbone of any cold room refrigeration system, playing a pivotal role in maintaining the desired temperature. High-quality insulation materials minimize heat transfer, ensuring that the internal temperature remains stable despite external fluctuations. Effective temperature control mechanisms, such as thermostats and monitoring systems, are also vital to guarantee that your cold room operates within specified limits.

When considering What is cold room refrigeration system?, it’s essential to understand how insulation impacts energy consumption and operational costs. Poor insulation can lead to excessive energy use as cooling systems work harder to compensate for heat loss. Therefore, investing in robust insulation solutions not only enhances efficiency but also extends the lifespan of your refrigeration equipment.

Layout and Space Optimization

The layout of a cold room significantly influences its functionality and efficiency in refrigeration processes. A well-designed space optimizes airflow and facilitates easy access to stored items, which is crucial for operations in busy commercial environments. When planning your layout, consider shelving options that maximize vertical space while allowing for proper air circulation around products.

Space optimization goes hand-in-hand with understanding Which refrigerant is best for a cold room? Different refrigerants require varying considerations regarding storage practices and equipment specifications. By creating an efficient layout, businesses can enhance their operational workflow while ensuring compliance with safety standards related to refrigerant handling.

Choosing the Right Equipment

Selecting suitable equipment is critical when designing an efficient cold room refrigeration setup. Factors such as size, capacity, and functionality should align with your specific storage needs and operational goals. The Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit stands out as an ideal choice due to its advanced cooling capabilities tailored for small to mid-sized applications.

This innovative unit not only provides excellent performance but also promotes sustainability—an increasingly important consideration in today's eco-conscious market. Understanding Will a refrigerator work in a cold room? becomes easier when you realize that specialized units like Arctic Active Cooling are engineered specifically for these environments, offering reliability where conventional refrigerators may falter.

In summary, effective design considerations encompassing insulation quality, spatial arrangement, and appropriate equipment selection play essential roles in optimizing cold room refrigeration systems across various industries.

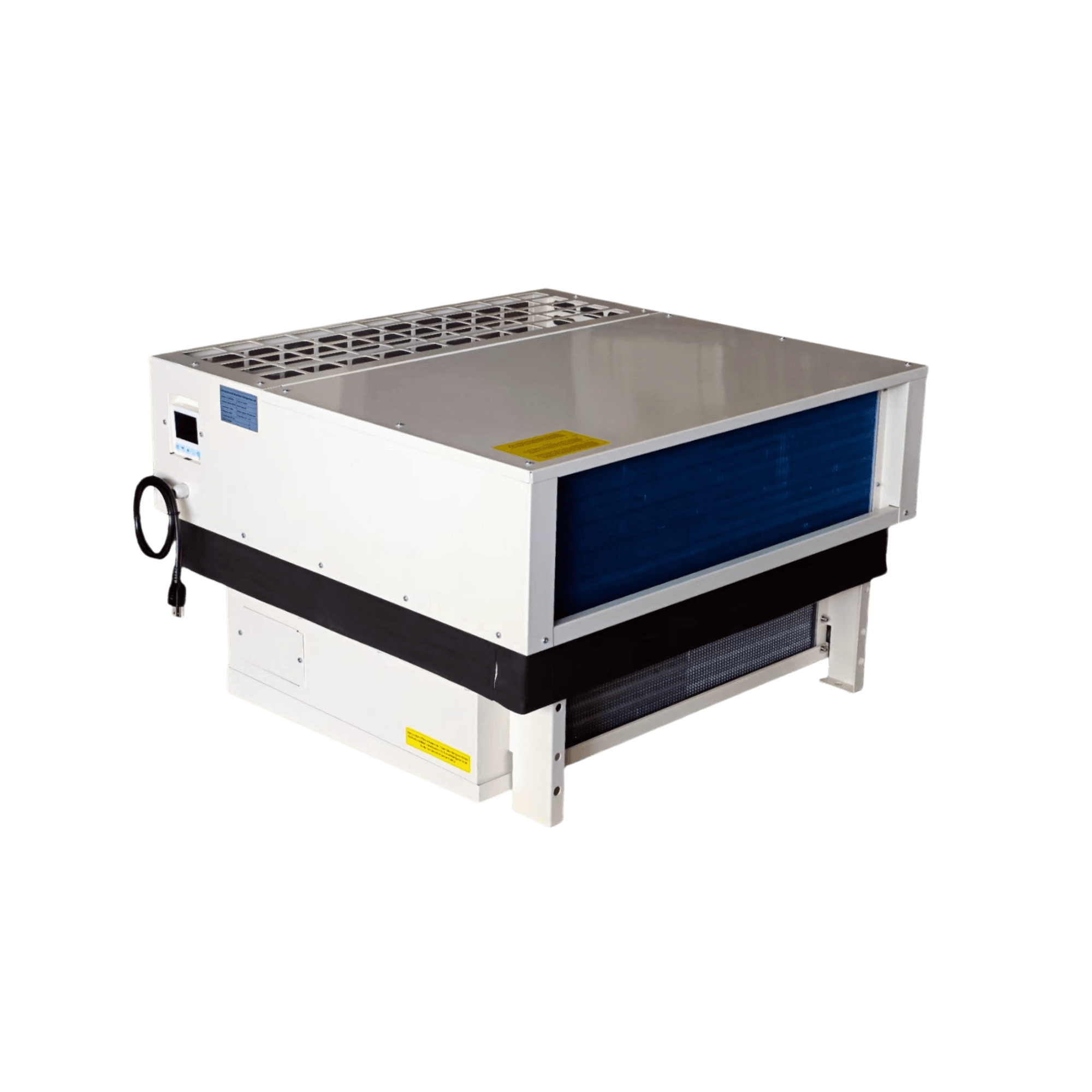

Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit

When it comes to cold room refrigeration, the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit stands out as a premier choice for efficient cooling solutions. This innovative unit is specifically designed for commercial refrigerators, freezers, and small to mid-sized cold rooms, ensuring that your perishables stay fresh and safe. With its advanced technology, businesses can expect unparalleled reliability and performance in their refrigeration systems.

Key Features and Benefits

The Arctic Active Cooling unit is packed with features that make it ideal for any cold room refrigeration setup. Its top-mounted design allows for easy access during maintenance while maximizing space efficiency within the cold room. Additionally, the monoblock system integrates all essential components into a single unit, simplifying installation and reducing the need for extensive ductwork.

Moreover, this refrigeration system is engineered to be energy-efficient, which helps businesses save on operational costs while minimizing their environmental footprint. The use of high-quality materials ensures durability and longevity, allowing companies to invest in a solution that will last for years without frequent replacements or repairs. Ultimately, choosing this unit means opting for a reliable partner in maintaining optimal temperatures in your cold room.

Installation and Maintenance Tips

Installing the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit requires careful planning to ensure maximum efficiency from day one. It’s essential to assess your specific needs based on what you are storing—whether it's food products or pharmaceuticals—and determine the appropriate size of the unit accordingly. Proper placement within your cold room can also enhance airflow and cooling efficiency.

Regular maintenance is crucial to keep this system running smoothly over time; routine checks should include cleaning condenser coils and ensuring that filters are clear of debris. It's advisable to schedule professional inspections at least once a year to catch potential issues early before they escalate into costly repairs or downtime in your cold room refrigeration operations. Keeping an eye on refrigerant levels will also help maintain optimal performance throughout its lifespan.

Case Studies of Successful Implementations

Numerous businesses have successfully integrated the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit into their cold room refrigeration setups with impressive results. For instance, a local grocery store upgraded its aging refrigeration systems with this modern solution and reported a significant reduction in energy costs while enhancing product freshness across all perishable items stored inside their walk-in cooler.

Another case involved a pharmaceutical company that required strict temperature controls for vaccine storage; by implementing this monoblock unit, they were able to achieve consistent temperatures while complying with regulatory standards efficiently. These examples highlight how effective cold room refrigeration systems like Arctic’s can transform operations across various industries by providing reliable cooling solutions tailored to specific needs.

Conclusion

Cold room refrigeration is an essential aspect of many industries, ensuring that perishable goods are stored at optimal temperatures. The effectiveness of a cold room refrigeration system hinges on its design, equipment, and the refrigerants used. As businesses increasingly prioritize efficiency and sustainability, understanding what cold room refrigeration entails becomes vital for making informed decisions.

Final Thoughts on Cold Room Refrigeration

Understanding what a cold room refrigeration system is can significantly impact operations in sectors like food storage, pharmaceuticals, and logistics. These systems not only preserve product quality but also help in reducing waste and enhancing profitability. As technology advances, the integration of smart systems into cold room refrigeration will further elevate efficiency and monitoring capabilities.

Benefits of Walk-In Cold Rooms for Businesses

Walk-in cold rooms offer numerous advantages that can transform business operations. They provide ample space for storing large quantities of perishable items while maintaining consistent temperatures—essential for any business relying on fresh inventory. Furthermore, investing in walk-in solutions enhances operational flexibility and can lead to significant cost savings over time.

Future Trends in Refrigeration Technology

The future of refrigeration technology promises exciting innovations that will revolutionize how we approach cold storage solutions. From energy-efficient refrigerants to advanced monitoring systems that optimize performance based on real-time data, the landscape is evolving rapidly. Additionally, products like Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit exemplify this trend by combining efficiency with reliability—ideal for modern cold rooms.