Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the world of precision engineering and manufacturing, maintaining optimal temperatures is crucial for the performance and longevity of equipment. This is where laser chillers come into play, particularly for CO2 lasers that are widely used across various industries. By utilizing an efficient chiller system, operators can ensure their laser equipment runs smoothly, thereby enhancing productivity and reducing downtime.

Understanding the Importance of Laser Chill

Laser chillers are essential for managing heat generated during laser operations, especially in CO2 lasers that often produce significant thermal output. Without a proper cooling mechanism like a water cooled chiller, these lasers can overheat, leading to decreased efficiency and potential damage. Understanding the importance of laser chill systems allows businesses to invest wisely in cooling solutions that extend equipment lifespan while optimizing performance.

The Role of CO2 Lasers in Industry

CO2 lasers have become indispensable tools in industries such as manufacturing, healthcare, and telecommunications due to their versatility and precision. These lasers are used for cutting, engraving, welding, and even medical procedures—tasks that require consistent power output and accuracy. To achieve this level of performance consistently, integrating a reliable chiller cooling water system is vital for maintaining stable operating temperatures.

An Overview of Chiller Systems

Chiller systems play a pivotal role in keeping industrial equipment at optimal temperatures by circulating cool water through components that generate heat. A well-designed water chiller not only prevents overheating but also enhances overall system efficiency by minimizing energy consumption during operation. With various types available on the market today—including compact models like Arctic Active Cooling's Mini Water Chiller—businesses have access to innovative solutions tailored to their specific cooling needs.

What is a CO2 Laser Chiller

CO2 laser chillers are essential components in maintaining the optimal performance of CO2 lasers used in various industrial applications. These specialized water chillers help regulate the temperature of laser systems, ensuring they operate efficiently and effectively. By cooling the laser's components, these systems prevent overheating and prolong equipment lifespan.

The Science Behind Laser Chill

At the core of any effective chiller system is the principle of heat exchange, which allows for efficient removal of excess heat generated by CO2 lasers during operation. The process involves circulating cool water through a series of coils or tubes that absorb heat from the laser system, thereby maintaining a stable operating temperature. This science behind laser chillers ensures that lasers can perform consistently without interruptions caused by thermal stress.

The cooling process is crucial because excessive heat can lead to reduced performance and potential damage to sensitive components within the CO2 laser setup. Efficient chiller cooling water systems not only enhance operational efficiency but also contribute to improved quality in products manufactured using these lasers. Understanding this science helps users appreciate why investing in high-quality water cooled chillers is vital for their operations.

Types of Laser Chill Systems

There are several types of laser chill systems available on the market, each designed to meet specific needs based on application requirements and operational environments. Among these, air-cooled and water-cooled chillers are two primary categories; both serve to regulate temperatures but differ significantly in their mechanisms and efficiency levels. Water cooled chillers tend to be more efficient than air-cooled options due to their ability to dissipate heat more effectively through direct contact with cool water.

Within these categories, you can find mini water chillers tailored for compact spaces or specific applications that require precise temperature control without taking up too much room. For instance, Arctic Active Cooling's Mini Water Chiller features an integrated design that combines multiple refrigeration parts into one unit, making it ideal for those who need a portable solution without compromising on performance. Choosing between different types of chiller systems ultimately depends on factors such as space constraints, cooling requirements, and budget considerations.

Key Components of a CO2 Laser Chiller

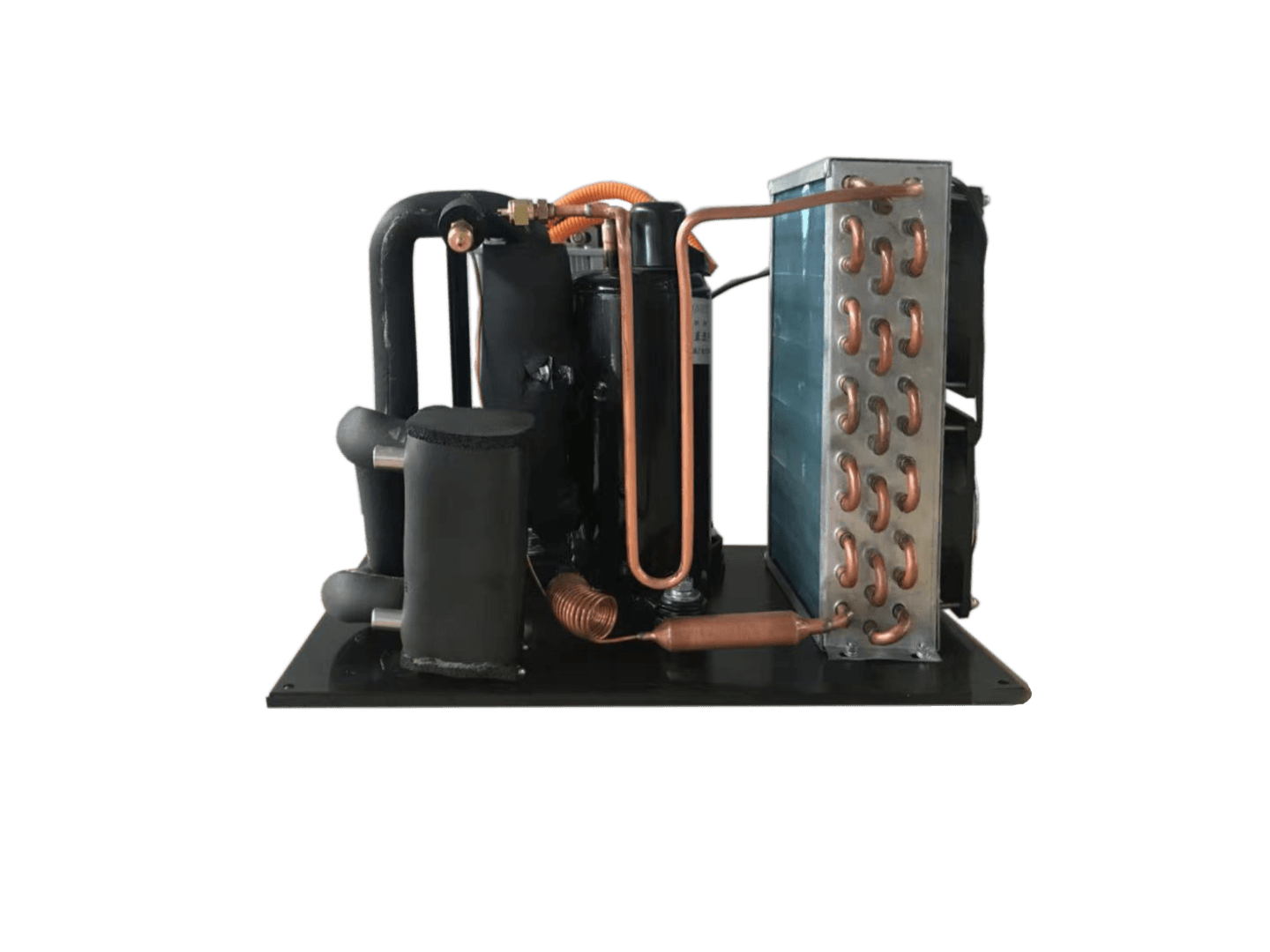

Understanding the key components of a CO2 laser chiller is essential for anyone looking to invest in one for their operations. Typically, these systems include a refrigeration compressor, condenser, evaporator plate, filter drier, and various sensors or controls necessary for optimal functionality. Each component plays a critical role; for example, the compressor circulates refrigerant while absorbing heat from the chiller cooling water.

Moreover, advanced designs like those found in Arctic Active Cooling's Mini Water Chiller integrate all refrigeration parts seamlessly into one compact unit. This sophisticated construction not only simplifies installation but also ensures reliable performance across varying conditions—ideal for users who want hassle-free operation without sacrificing quality or efficiency. A well-designed water chiller will ultimately enhance your overall experience with CO2 lasers by providing stable temperatures and minimizing downtime due to overheating issues.

How a CO2 Laser Chiller Works

Understanding how a CO2 laser chiller operates is essential to appreciate its role in maintaining optimal performance for laser systems. At its core, the chiller system utilizes a carefully designed process to ensure that the cooling water remains at an ideal temperature, thus preventing overheating of the laser components. This efficient management of heat allows for continuous operation and enhances productivity in various industrial applications.

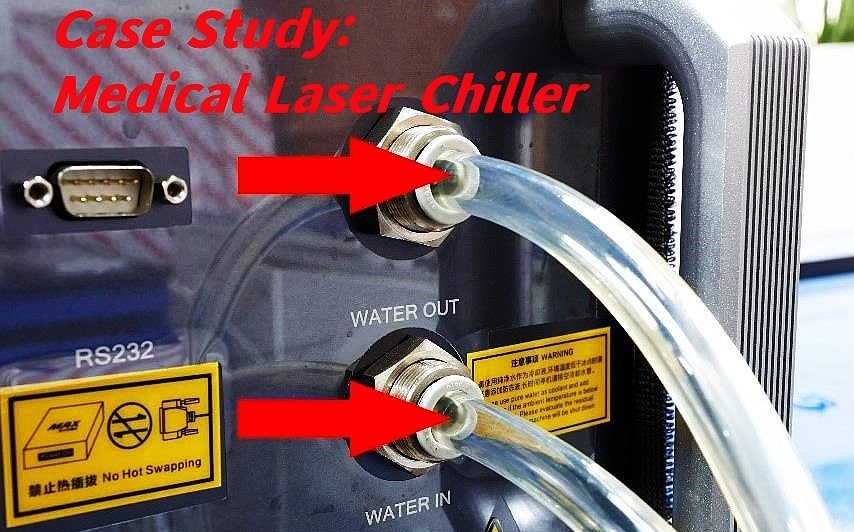

The Chiller Cooling Water Process

The chiller cooling water process begins with the circulation of water through the CO2 laser system. As the laser operates, it generates heat, which is absorbed by the cooling water circulating within the system. This heated water then flows back to the chiller unit, where it undergoes a cooling process before being recirculated, ensuring that consistent cool water is supplied to maintain optimal temperatures.

The effectiveness of this process hinges on several factors, including flow rate and temperature differential between inlet and outlet points. A well-designed water chiller ensures that these elements are optimized for maximum efficiency, allowing users to benefit from enhanced performance and longevity of their CO2 lasers. Regular maintenance of this cooling system is crucial; any disruption can lead to decreased efficiency or even equipment failure.

The Function of a Water Cooled Chiller

A water cooled chiller plays a pivotal role in managing thermal loads generated by CO2 lasers during operation. By utilizing ambient air as part of its cooling mechanism, this type of chiller effectively dissipates heat away from critical components, ensuring they remain within safe operating limits. This function not only protects sensitive parts but also enhances overall operational stability.

Moreover, with advancements in technology like Arctic Active Cooling’s Mini Water Chiller, users can enjoy compact designs without sacrificing performance quality. The integration of high-efficient refrigeration components allows for precise control over coolant temperatures while minimizing energy consumption—a win-win situation for both productivity and sustainability! Properly functioning water chillers are essential for maintaining consistent output quality in laser applications.

Understanding Laser Chiller Efficiency

Laser chiller efficiency is measured by how effectively it can remove heat from the laser system while consuming minimal energy resources. A highly efficient chiller minimizes operating costs by reducing electricity consumption while maximizing output performance—essentially giving you more bang for your buck! Factors influencing efficiency include design features such as compressor technology and heat exchanger configurations found in modern systems like those offered by Arctic Active Cooling.

Additionally, regular maintenance practices such as cleaning filters and checking refrigerant levels play an important role in maintaining peak efficiency levels over time. When selecting a cool water chiller for your application, it’s vital to consider these aspects alongside initial purchase costs—after all, investing in an efficient system can lead to significant long-term savings!

Benefits of Using Laser Chill Systems

When it comes to operating CO2 lasers, the importance of an efficient chiller system cannot be overstated. Laser chillers play a crucial role in maintaining optimal performance and ensuring longevity for these powerful machines. By utilizing advanced technology, water cooled chillers help regulate temperatures effectively, allowing for consistent operation without the risk of overheating.

Enhancing Performance of CO2 Lasers

The primary benefit of using laser chillers is the enhancement they provide to CO2 laser performance. With a reliable cooling system in place, operators can achieve higher output power and improved beam quality, which translates into better cutting and engraving results. The chiller cooling water circulates efficiently through the laser's components, preventing thermal fluctuations that could otherwise degrade performance.

Moreover, consistent cooling allows for faster processing speeds without compromising quality. In industries where precision is paramount, such as aerospace or automotive manufacturing, having a dependable water chiller ensures that the laser maintains its specifications over time. This enhanced performance not only boosts productivity but also increases competitiveness in a fast-paced market.

Extending Equipment Lifespan

Another significant advantage of implementing a water cooled chiller in your setup is its ability to extend the lifespan of your equipment. CO2 lasers are substantial investments; thus, maintaining their health through effective cooling is essential for long-term use. By keeping critical components within safe temperature ranges with a cool water chiller, operators can drastically reduce wear and tear on their systems.

Overheating can lead to premature failures or costly repairs; however, with an efficient chiller system managing heat dissipation effectively, users can enjoy years of reliable service from their laser equipment. Additionally, regular maintenance on these systems ensures that potential issues are identified early on before they escalate into more serious problems requiring expensive interventions.

Energy Savings with Efficient Cooling

In today's environmentally conscious world, energy efficiency has become increasingly important across all sectors—including industrial applications like CO2 lasers. Utilizing modern laser chillers not only optimizes cooling but also significantly reduces energy consumption compared to older models or inadequate systems. Water chillers designed specifically for these applications often incorporate advanced technologies that minimize power usage while maximizing output.

By investing in efficient chiller systems such as Arctic Active Cooling's Mini Water Chiller—which integrates high-efficiency refrigeration components—users benefit from lower operational costs while still achieving optimal cooling performance for their lasers. This dual advantage enhances both profitability and sustainability efforts within organizations striving to minimize their carbon footprint while maximizing productivity.

Choosing the Right Water Chiller

Selecting the right water chiller for your CO2 laser system is crucial for optimal performance and longevity. With various options available, understanding the specific needs of your application can help you make an informed decision. This section will guide you through factors to consider, comparisons of mini water chillers, and a spotlight on Arctic Active Cooling's offerings.

Factors to Consider When Selecting a Chiller

When choosing a chiller system, several factors come into play to ensure it meets your operational requirements effectively. First, consider the cooling capacity; it must be adequate to maintain optimal temperatures during laser operation without overworking the unit. Additionally, pay attention to energy efficiency ratings and noise levels since these can impact both operating costs and workplace comfort when using laser chillers.

Another critical factor is compatibility with your existing equipment; ensure that any water cooled chiller you choose integrates seamlessly with your CO2 laser setup. Look for features such as adjustable flow rates and temperature settings that allow fine-tuning of chiller cooling water according to specific tasks or materials being processed. Lastly, don't overlook maintenance requirements; a good chiller should offer easy access for routine checks to keep everything running smoothly.

Comparing Mini Water Chilllers for CO2 Lasers

Mini water chillers are particularly popular in settings where space is limited but cooling efficiency remains paramount. When comparing different models, look at their size versus performance ratio—some compact units pack quite a punch while maintaining minimal footprint! Assessing user reviews can also provide insights into real-world performance and reliability of these laser chillers.

Consider features such as dual temperature control or built-in alarms that alert users when maintenance is needed or if there's an operational issue with the cool water chiller. Furthermore, evaluate how easily each model connects with your existing systems; some may offer plug-and-play functionality while others require more complex integration efforts. Ultimately, finding a balance between size, efficiency, and ease of use will lead you toward the best choice for your CO2 laser application.

Arctic Active Cooling's Mini Water Chiller Features

Arctic Active Cooling has engineered its Mini Water Chiller with cutting-edge technology tailored specifically for users who value high efficiency in compact designs. This model consists of a high-efficient refrigeration mini compressor utilizing R134a coolant along with an exceptionally small condenser and plate evaporator—all integrated into one sophisticated unit designed by skilled engineers. Such thoughtful design not only simplifies installation but also ensures users have access to state-of-the-art micro cooling solutions.

The Mini Water Chiller is ideal for customers who prefer modular systems that allow them to control their own cooling subsystems directly—offering flexibility in how they integrate it with their machines or equipment setups. The ability to connect their control board with our BLDC compressor driver board enables precise adjustments in compressor speed tailored to individual cooling needs—a feature that enhances overall performance significantly! By keeping engineering practices up-to-date, Arctic continues delivering portable commercial refrigeration systems suitable for both OEM and ODM projects.

Maintenance and Troubleshooting Tips

Maintaining your CO2 laser chiller is crucial for ensuring optimal performance and longevity. Regular checkups not only help identify potential issues before they escalate but also keep your chiller system operating smoothly. By following a diligent maintenance routine, you can enhance the efficiency of your water cooled chiller and minimize downtime.

Regular Checkups for Optimal Performance

To maximize the effectiveness of your laser chillers, it's essential to conduct regular inspections. This includes checking the coolant levels, inspecting hoses for leaks, and ensuring that filters are clean to allow proper chiller cooling water flow. Additionally, monitoring temperature readings can help identify any deviations that may indicate underlying problems with the water chiller.

Regular maintenance should also involve cleaning components like heat exchangers or condensers to prevent dust accumulation that could hinder performance. A well-maintained CO2 laser chiller not only operates more efficiently but can also save on energy costs over time. Ultimately, consistent upkeep will lead to a longer lifespan for both the chiller system and the laser itself.

Common Issues with Water Chillers

Even with diligent care, water chillers may encounter common issues that can disrupt their functionality. One frequent problem is insufficient cooling due to low coolant levels or blockages in the cooling lines; this can lead to overheating of the CO2 laser if left unaddressed. Another issue might be pump failure, which could prevent proper circulation of cool water through the system.

In some cases, users may experience unusual noise or vibrations from their mini water chillers—this could indicate mechanical wear or misalignment within components like compressors or fans. Identifying these problems early through regular checkups will help you avoid costly repairs down the line. Knowing how to troubleshoot these common issues empowers you as an operator while keeping your equipment running smoothly.

How to Extend the Life of Your CO2 Laser Chiller

Extending the life of your CO2 laser chiller involves a combination of proactive maintenance practices and smart operational choices. First off, ensure that you are using high-quality coolant specifically designed for your system; this can significantly impact its efficiency and longevity. Additionally, consider investing in an advanced model like Arctic Active Cooling's Mini Water Chiller, which boasts a sophisticated design integrated with efficient refrigeration parts.

Another effective way to prolong your cool water chiller's lifespan is by avoiding overloading it with excessive workload beyond its rated capacity—this helps prevent overheating and premature wear on critical components like compressors and pumps. Lastly, training staff on proper usage techniques ensures that everyone understands how to operate and maintain these systems effectively without causing unnecessary strain on them.

Conclusion

In summary, CO2 laser chillers play a crucial role in maintaining optimal operating temperatures for laser systems, ensuring their efficiency and longevity. These chiller systems utilize advanced technology to circulate cool water chiller solutions, preventing overheating and enhancing performance. Understanding the functions of these sophisticated devices is essential for anyone involved in the laser industry.

Recap of CO2 Laser Chiller Functions

CO2 laser chillers are designed to manage the thermal output of high-powered lasers by circulating chilled water through the system. This process involves the efficient transfer of heat away from critical components, allowing for consistent operation without performance degradation. By utilizing a well-designed chiller cooling water system, users can ensure that their laser equipment operates at peak efficiency.

Benefits of Using Efficient Chiller Systems

The advantages of using efficient chiller systems extend far beyond mere temperature control; they also significantly enhance the overall performance and lifespan of CO2 lasers. With proper cooling from a reliable water cooled chiller, users can expect reduced wear on equipment and increased reliability during operation. Additionally, energy savings associated with modern cool water chiller designs can lead to lower operational costs over time.

Future Trends in Laser Cooling Technology

As technology continues to advance, we can expect exciting developments in laser cooling solutions that will further improve efficiency and integration capabilities. Innovations such as Arctic Active Cooling's Mini Water Chiller exemplify this trend with their compact design and high-efficiency refrigeration systems tailored for specific user needs. The future may also see more eco-friendly refrigerants and smarter control systems that enhance user experience while reducing environmental impact.