Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the ever-evolving landscape of refrigeration technology, the BLDC compressor stands out as a game-changer, offering enhanced efficiency and performance. But what exactly is a BLDC compressor? As we delve into this fascinating world, we'll uncover its key features, especially in refrigerators, and explore why choosing a BLDC compressor can be a smart decision for both consumers and manufacturers alike.

Exploring the World of BLDC Compressors

BLDC stands for Brushless Direct Current, which highlights the innovative design behind these compressors. Unlike traditional compressors that rely on brushes to create motion, BLDC compressors utilize electronic commutation to enhance reliability and efficiency. This shift not only reduces wear and tear but also opens up new possibilities in terms of energy savings and performance optimization.

Key Features of BLDC Refrigerators

BLDC refrigerators come equipped with advanced technology that sets them apart from their linear counterparts. One prominent feature is their ability to adjust speed according to cooling needs, ensuring optimal energy consumption without compromising performance. Additionally, these refrigerators tend to operate more quietly than traditional models, making them ideal for homes where noise levels are a concern.

Benefits of Choosing a BLDC Compressor

Choosing a BLDC compressor offers numerous advantages that can significantly impact your refrigeration experience. For starters, they are known for their superior energy efficiency compared to linear compressors; this translates into lower electricity bills over time. Furthermore, with reduced noise levels during operation and enhanced durability due to fewer moving parts, it's clear why many are making the switch to BLDC technology in their refrigeration systems.

Understanding BLDC Compressors

In the world of refrigeration, the term BLDC compressor is becoming increasingly prominent. These innovative devices are revolutionizing how refrigerators operate, offering enhanced efficiency and performance. Let’s delve into what exactly a BLDC compressor is and how it stands out in the crowded field of cooling technology.

What is BLDC Compressor?

A BLDC compressor, or Brushless Direct Current compressor, is an advanced type of electric motor that drives refrigeration systems. Unlike traditional compressors that rely on brushes for operation, a BLDC compressor uses electronic commutation to control motor speed and torque more effectively. This results in improved efficiency and a longer lifespan for the appliance, making it an excellent choice for modern refrigerators.

When you ask, What is BLDC compressor? think of it as the brain behind energy-efficient cooling solutions that minimize energy consumption while maximizing performance. The absence of brushes reduces wear and tear on components, which translates to less maintenance over time. This innovation not only benefits your wallet but also contributes to a more sustainable environment.

What does BLDC stand for?

The acronym BLDC stands for Brushless Direct Current. This name reflects the core technology behind these compressors: they utilize direct current without the need for brushes to transfer electricity within the motor system. As such, they are designed to operate smoothly and quietly compared to their brushed counterparts.

Understanding what does BLDC stand for can help you appreciate its advantages over traditional systems—primarily in terms of efficiency and reliability. The brushless design minimizes friction losses, leading to higher overall performance in refrigeration applications like those found in a typical BLDC compressor refrigerator.

Key Components of a BLDC System

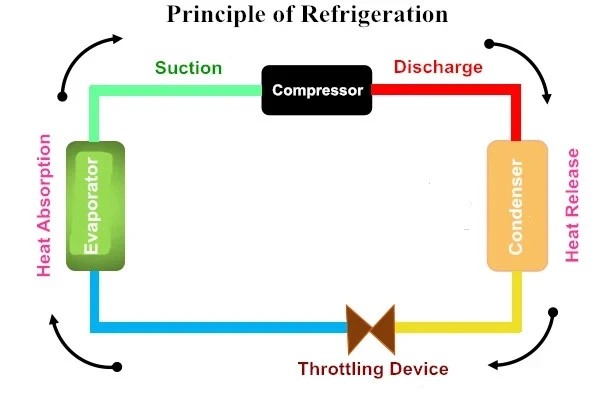

A typical BLDC system consists of several key components that work together seamlessly: the rotor, stator, controller, and sensors are among them. The rotor contains permanent magnets that interact with electromagnetic fields generated by the stator coils when powered by direct current from a controller unit. Advanced sensors monitor various parameters like speed and temperature to ensure optimal performance.

The integration of these components allows a BLDC inverter compressor not only to maintain precise temperature controls but also adapt its operation based on real-time demands—something crucial in modern refrigeration technology. With fewer moving parts than conventional compressors, maintenance requirements are significantly reduced while enhancing reliability across various applications—from household refrigerators to commercial cooling units.

Comparing BLDC and Linear Compressors

What is the difference between BLDC and linear compressor?

The primary distinction between a BLDC compressor and a linear compressor lies in their operational mechanisms. A BLDC compressor utilizes brushless direct current technology, which allows for smoother operation with less wear over time. In contrast, a linear compressor functions through a linear motion mechanism that directly compresses refrigerant without the need for rotating components.

Another key difference is energy consumption; BLDC compressors often provide higher energy efficiency compared to their linear counterparts due to their advanced control systems. Furthermore, while both can be used in various refrigeration applications, the choice may ultimately depend on specific needs such as noise level or space constraints. Understanding these differences helps consumers make better choices when selecting a BLDC compressor refrigerator or any other cooling system.

Efficiency Metrics Explained

Efficiency metrics are essential when comparing the performance of BLDC compressors against linear compressors. One of the most significant metrics is the coefficient of performance (COP), which measures how effectively a system converts electrical energy into cooling power. Generally speaking, BLDC compressors tend to have higher COP values due to their ability to adjust motor speed based on demand, leading to less energy waste.

Moreover, energy consumption is another vital metric; many modern BLDC inverter compressors are designed with features that minimize electricity use while maximizing output efficiency. This makes them particularly appealing for environmentally conscious consumers looking for sustainable options in refrigeration technology. By examining these efficiency metrics closely, one can appreciate why many prefer a BLDC inverter compressor over traditional options.

Performance in Refrigeration Applications

When it comes to performance in refrigeration applications, both types of compressors have unique strengths that cater to different requirements. The adaptability of a BLDC compressor allows it to maintain consistent temperatures even under varying load conditions—making it ideal for environments where temperature stability is critical. Its rapid response time also means that cooling can be achieved quickly without excessive cycling.

On the other hand, linear compressors excel at providing precise temperature control but may not always match the flexibility offered by their BLDC counterparts when handling fluctuating demands. Additionally, noise levels play an important role; typically, you will find that many users prefer the quieter operation associated with modern BLDC designs compared to traditional models like linear compressors. Ultimately, understanding these performance factors will guide consumers toward selecting the right solution tailored specifically for their needs.

The Role of PMSM in BLDC Technology

When diving into the realm of BLDC compressors, understanding the role of Permanent Magnet Synchronous Motors (PMSM) is crucial. While both PMSMs and traditional BLDC motors share similarities, they have distinct differences that affect their performance and applications. Essentially, PMSMs utilize permanent magnets to create a consistent magnetic field, which enhances efficiency and control in various refrigeration systems.

What is the difference between PMSM and BLDC?

The primary difference between PMSM and standard BLDC motors lies in their operational characteristics. While both types use electricity to generate motion, PMSMs operate with a more constant speed due to their design, making them particularly suitable for applications requiring precise control like a BLDC compressor refrigerator. On the other hand, standard BLDC motors can experience fluctuations in speed under varying loads, which may not be ideal for all refrigeration scenarios.

Advantages of Permanent Magnet Synchronous Motors

PMSMs come with several advantages that make them stand out in the world of refrigeration technology. First off, they offer superior energy efficiency compared to traditional motors; this efficiency translates directly into lower energy bills for consumers using a BLDC inverter compressor. Additionally, their ability to maintain consistent torque at different speeds means that refrigerators equipped with these motors can operate quietly while providing optimal cooling performance.

Applications in Modern Refrigeration

The integration of PMSMs into modern refrigeration systems has transformed how we view energy consumption and performance standards. In particular, a BLDC compressor refrigerator utilizing PMSM technology can achieve remarkable cooling efficiencies while minimizing noise levels during operation. As manufacturers continue to innovate using this technology, we can expect even more advancements that will further enhance our everyday appliances' efficiency and reliability.

Features of BLDC Inverter Compressors

BLDC inverter compressors are revolutionizing the refrigeration landscape, offering a blend of efficiency and performance that traditional systems struggle to match. Understanding how these advanced compressors operate is essential for anyone looking to invest in a BLDC compressor refrigerator. With their sophisticated technology, they provide significant advantages over conventional models.

How BLDC inverter compressor works

A BLDC inverter compressor operates by utilizing a brushless direct current motor, allowing for precise control of the compressor's speed and power consumption. This means that instead of running at a fixed speed, like traditional compressors, the BLDC inverter compressor can adjust its operation based on the cooling demand. As a result, it delivers consistent temperatures while minimizing energy usage—an essential feature for any modern refrigerator.

In essence, what is a BLDC compressor? It’s an innovative solution designed to enhance efficiency and performance in refrigeration applications. The ability to modulate its speed not only contributes to lower energy costs but also extends the lifespan of the appliance by reducing wear and tear.

Energy Efficiency Benefits

One of the standout features of a BLDC inverter compressor is its remarkable energy efficiency benefits. Compared to traditional linear compressors, which often operate at full capacity regardless of need, a BLDC inverter compressor can significantly reduce electricity consumption by adjusting its output according to actual cooling requirements. This adaptability translates into lower utility bills and reduced environmental impact—a win-win for both consumers and our planet.

What does BLDC stand for? It stands for Brushless Direct Current, emphasizing its advanced technology that allows for this impressive energy management capability. By choosing a refrigerator equipped with a BLDC inverter compressor, users can enjoy substantial savings without sacrificing performance or reliability.

Noise Reduction in Operation

Another compelling advantage of using a BLDC inverter compressor is the noise reduction during operation. Traditional compressors tend to create noticeable sounds as they cycle on and off; however, with their variable speed capabilities, BLDC compressors operate more quietly throughout their cooling cycles. This means you can enjoy your kitchen or living space without disruptive noise from your refrigerator.

What is the difference between PMSM and BLDC? While both technologies share similarities in their use of permanent magnets for efficiency gains, PMSM (Permanent Magnet Synchronous Motor) typically offers even higher performance levels than standard brushless motors found in basic BLDC designs. Ultimately, this results in quieter operations across various applications—including modern refrigerators featuring advanced designs like those utilizing the latest generation of BLDC inverter compressors.

Choosing the Right BLDC Compressor for Refrigerators

When it comes to selecting the perfect BLDC compressor for your refrigerator, there are several factors to consider. The effectiveness of a BLDC compressor can significantly impact energy efficiency, noise levels, and overall performance in refrigeration applications. Understanding what features are most important will help you make an informed decision that aligns with your needs.

Factors to Consider

First and foremost, consider the size and capacity of the BLDC compressor needed for your refrigerator. Different models have varying cooling capacities, so it's crucial to match the right size with your refrigeration requirements. Additionally, energy efficiency is a key factor; look for models that boast high EER (Energy Efficiency Ratio) ratings to save on electricity bills while keeping food fresh.

Another important consideration is noise level during operation. Many consumers prefer quieter appliances, especially in open-plan living spaces or kitchens where noise can be disruptive. Opting for a BLDC inverter compressor often results in reduced operational noise compared to traditional compressors due to their ability to adjust speed based on cooling demand.

Lastly, think about durability and maintenance requirements when selecting a BLDC compressor refrigerator. Research brands known for reliability and check user reviews regarding long-term performance and servicing needs. By weighing these factors carefully, you can ensure that your chosen compressor meets both performance expectations and lifestyle demands.

ARCTIC Micro & Miniaturized Compressors

ARCTIC micro and miniaturized compressors represent some of the most innovative advancements in BLDC technology today. These compact units are designed specifically for space-constrained environments while still delivering impressive cooling capabilities typical of larger models. What sets them apart is their efficiency; they utilize advanced engineering to minimize energy consumption while maximizing output.

The ARCTIC line also features enhanced temperature control mechanisms that allow these small yet mighty compressors to maintain optimal cooling conditions effectively. This makes them ideal not just for household refrigerators but also for specialized applications like portable coolers or medical refrigeration units where precision is key.

In addition to their compact design and efficiency benefits, ARCTIC compressors often come equipped with smart technology features that allow users better control over settings through mobile apps or integrated systems—adding another layer of convenience in today’s tech-savvy world.

Compatibility with Existing Systems

One critical aspect when choosing a BLDC compressor is its compatibility with existing systems or appliances you may already have at home or work. Before making a purchase, check whether the dimensions and specifications align with your current setup; this includes power supply requirements as well as physical space constraints within your fridge design.

Furthermore, if you're replacing an older model—perhaps wondering what is the difference between BLDC and linear compressors—you'll want assurance that the new unit integrates smoothly without requiring extensive modifications or additional components. A seamless transition not only saves time but also reduces installation costs associated with retrofitting other parts.

Finally, consult product documentation or reach out directly to manufacturers if uncertain about compatibility issues—especially if you're considering newer technologies like PMSM (Permanent Magnet Synchronous Motors) versus traditional options such as standard AC motors found in linear compressors. This diligence ensures you choose a reliable solution tailored specifically toward enhancing your refrigeration experience without unnecessary headaches down the line.

Conclusion

In wrapping up our exploration of the BLDC compressor, it’s clear that these innovative devices are reshaping the refrigeration landscape. The BLDC compressor offers numerous advantages, including energy efficiency, reduced noise levels, and enhanced performance compared to traditional compressors. As we’ve learned throughout this discussion, understanding what a BLDC compressor is and how it differs from linear compressors can empower consumers to make informed decisions.

Summarizing BLDC Compressor Benefits

The benefits of a BLDC compressor are hard to ignore. First off, they deliver superior energy efficiency, which translates into lower electricity bills for households and businesses alike. Additionally, the quiet operation of a BLDC inverter compressor makes them an ideal choice for environments where noise reduction is essential—like kitchens or offices—making them a popular choice in modern appliances.

Moreover, when discussing what does BLDC stand for—Brushless Direct Current—it’s important to highlight how this technology contributes to longevity and reliability in refrigeration systems. Unlike traditional compressors that rely on brushes and mechanical components prone to wear and tear, the design of a BLDC compressor minimizes friction and maximizes durability. All these factors combined make a compelling case for selecting a BLDC compressor refrigerator over conventional options.

Future of Refrigeration Technology

Looking ahead, the future of refrigeration technology appears bright with advancements in BLDC systems on the horizon. As energy efficiency becomes increasingly crucial amid global climate concerns, manufacturers are likely to invest more in developing smarter and more efficient compressors like those utilizing PMSM technology alongside traditional BLDC designs. The integration of IoT capabilities could also revolutionize how we interact with our refrigerators; imagine being able to monitor your refrigerator's performance remotely!

Furthermore, understanding what is the difference between PMSM and BLDC will become vital as these technologies evolve together in modern applications. Permanent Magnet Synchronous Motors (PMSM) offer unique advantages such as higher torque density and improved efficiency under varying loads compared to standard brushless designs. This synergy may lead us toward even greater innovation in cooling solutions.

Making Informed Choices for Efficiency

When it comes time to choose a refrigerator equipped with a high-performance compressor system, being well-informed about your options can save you money while ensuring optimal performance at home or work. Consider factors like energy ratings and compatibility with existing systems before making your decision on which type suits your needs best—especially when weighing choices between a standard model versus one featuring advanced technologies like the BLDC inverter compressor.

Also remember that understanding what is the difference between a BLDC compressor versus linear models can help clarify which option aligns best with your lifestyle requirements or business operations! By opting for cutting-edge solutions like those found within ARCTIC Micro & Miniaturized Compressors or other similar models available today, you’re not just making an investment; you’re contributing positively towards environmental sustainability.