Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

In the world of logistics and transportation, maintaining the integrity of perishable goods is paramount. This is where the truck refrigeration system plays a crucial role, ensuring that products remain at optimal temperatures throughout their journey. Understanding how these systems function and selecting the right unit can significantly impact efficiency and product quality.

Understanding Truck Refrigeration Systems

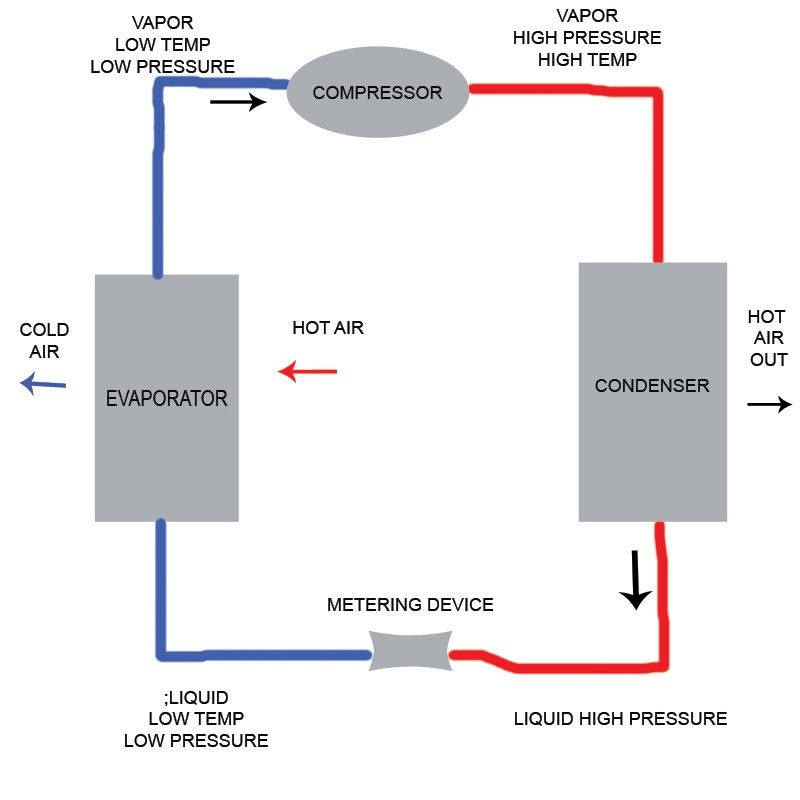

A truck refrigeration system operates by utilizing a combination of mechanical components to maintain low temperatures inside the cargo area. But how does a truck refrigeration unit work? Essentially, it circulates refrigerant through its four main components: the compressor, condenser, expansion valve, and evaporator. Each part plays a vital role in transforming refrigerant from gas to liquid and back again, effectively cooling down the interior space.

Importance of Choosing the Right Unit

Choosing the right unit for your needs is not just about picking any truck refrigeration system; it’s about finding one that aligns with your specific requirements. Different applications may call for varying types of cooling capabilities—considering factors like load size and temperature range is essential for optimal performance. Selecting an efficient commercial truck refrigeration unit manufacturer can also ensure you receive reliable support and service throughout your equipment's lifespan.

Key Features to Assess

When evaluating potential truck refrigeration systems, it's important to assess key features such as energy efficiency ratings, cooling capacity, and compatibility with different types of refrigerants. Factors like insulation quality can significantly influence how do truck fridges work in maintaining desired temperatures during transit. Additionally, understanding what refrigerant is used in refrigerated trucks will help you make informed decisions regarding environmental impact and regulatory compliance.

Overview of Truck Refrigeration Systems

Truck refrigeration systems are essential for transporting perishable goods safely and efficiently. Understanding how these systems operate and the differences between various types can help you make informed decisions when selecting the right unit for your needs. In this section, we will explore how a truck refrigeration unit works, compare truck refrigeration systems to van refrigeration units, and highlight the essential components that ensure optimal performance.

How Does a Truck Refrigeration Unit Work?

So, how does a truck refrigeration unit work? At its core, a truck refrigeration system operates by removing heat from the cargo area, thereby lowering its temperature to preserve perishable items during transport. This process typically involves four main components: the compressor, condenser, expansion valve, and evaporator—all working together in a continuous cycle to maintain the desired temperature range.

The compressor compresses refrigerant gas, increasing its pressure and temperature before sending it to the condenser. Here, heat is dissipated into the atmosphere as the refrigerant changes from gas to liquid. The liquid refrigerant then flows through an expansion valve into the evaporator, where it absorbs heat from inside the cargo area before returning to the compressor to restart this efficient cycle.

Differences Between Van Refrigeration Units and Truck Refrigeration Systems

When comparing van refrigeration units with truck refrigeration systems, several key differences emerge that can influence your choice of equipment. Van refrigeration units are typically smaller and designed for lighter loads or short-distance deliveries; they may not have as robust cooling capacities as larger truck systems. On the other hand, commercial truck refrigeration units are engineered for heavy-duty applications with higher cooling demands over longer distances.

Another significant difference lies in their configurations: van units often integrate directly into vehicle designs while maintaining aesthetics and aerodynamics; conversely, truck systems may feature external components that allow for more powerful cooling capabilities without compromising vehicle performance. Ultimately, understanding these distinctions helps businesses choose between van or truck solutions based on their specific transportation needs.

Essential Components of a Truck Refrigeration System

What are the 4 components of a refrigeration system? The primary components include: 1) compressor; 2) condenser; 3) expansion valve; and 4) evaporator—each playing an integral role in maintaining optimal temperatures within your refrigerated cargo space. The compressor is responsible for circulating refrigerant throughout the system while compressing it into high-pressure gas form.

The condenser cools down this gas by releasing heat outside before transforming it back into liquid form—ready for expansion through valves that regulate flow into evaporators where heat absorption occurs inside your cargo area. Proper insulation also plays an essential role in enhancing efficiency by minimizing temperature fluctuations during transport—a critical factor when dealing with sensitive products like fresh produce or pharmaceuticals.

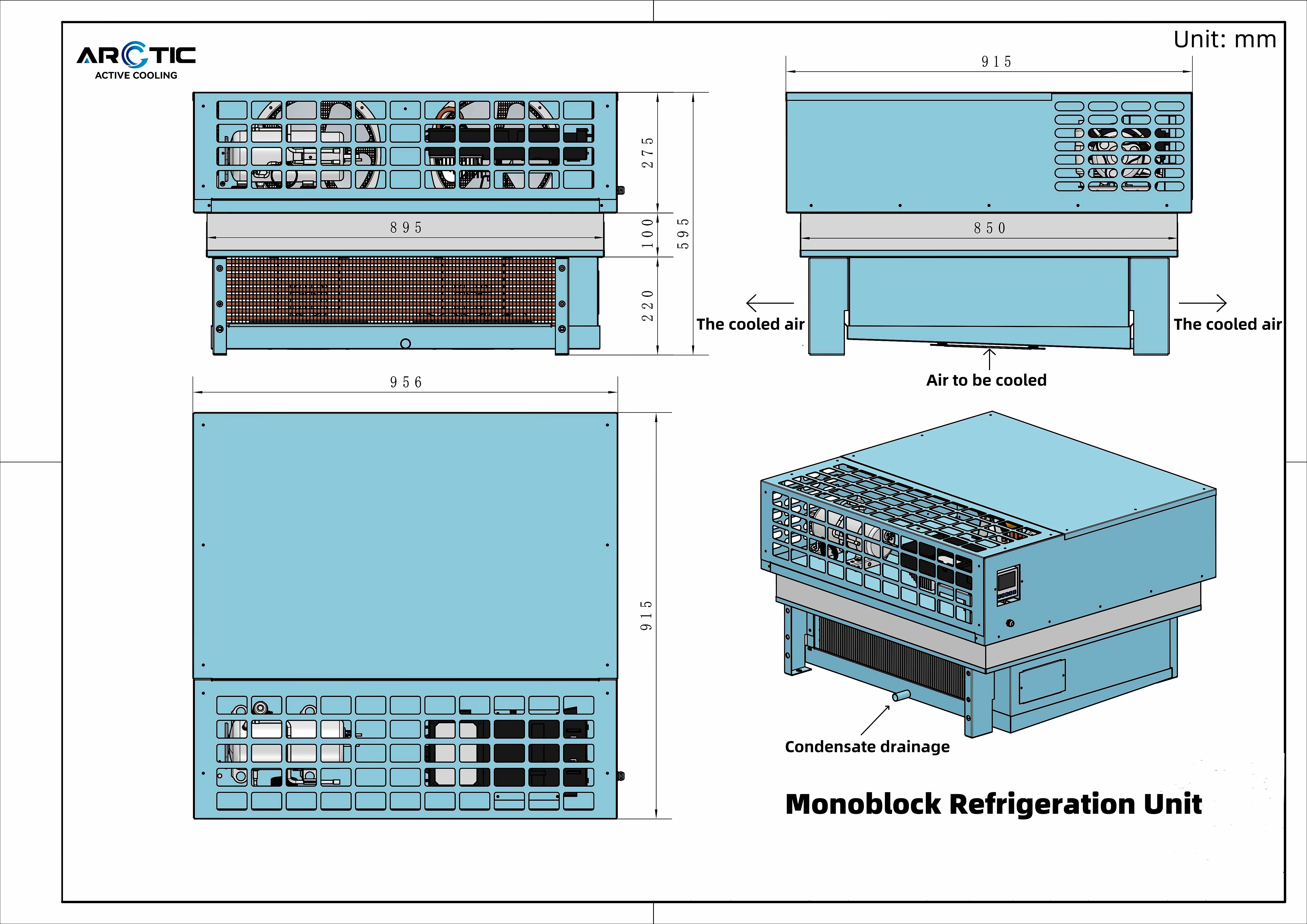

For businesses seeking reliable solutions that combine efficiency with advanced technology in their refrigerated transport needs—consider options like Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit designed specifically for commercial use! This innovative unit provides unparalleled performance while ensuring optimal humidity levels suitable even for delicate items such as fresh flowers stored at florists or wholesale markets.

Key Components of a Refrigeration System

Understanding the key components of a refrigeration system is essential for ensuring that your truck refrigeration system operates efficiently and effectively. Each component plays a critical role in maintaining the desired temperature and preserving the integrity of perishable goods during transport. By grasping how these parts work together, you can make informed decisions about your refrigeration needs.

What Are the 4 Components of a Refrigeration System?

The four primary components of a refrigeration system are the compressor, condenser, evaporator, and expansion valve. These elements work in harmony to facilitate heat exchange, which is fundamental to how does a truck refrigeration unit work? The compressor pressurizes refrigerant gas, while the condenser cools it down into liquid form; this liquid then passes through an expansion valve before entering the evaporator, where it absorbs heat from inside the truck fridge and evaporates back into gas.

Understanding what are the 4 components of a refrigeration system helps in troubleshooting potential issues as well. If one part malfunctions, it can lead to inefficient cooling or even complete failure of your truck fridge. Regular maintenance checks on these components can prevent costly repairs and ensure that your commercial truck refrigeration unit operates at peak performance.

Role of the Compressor in Refrigeration

The compressor is often dubbed the heart of any truck refrigeration system because it circulates refrigerant throughout the entire system. It compresses low-pressure refrigerant gas into high-pressure gas before sending it to the condenser for cooling. Without a functioning compressor, how do truck fridges work? They simply wouldn’t—no pressure means no circulation!

Moreover, understanding its role helps you appreciate why choosing a reliable commercial truck refrigeration unit manufacturer is crucial. A high-quality compressor ensures efficient operation and longevity of your refrigerated transport solution. If you’re considering options like Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit, rest assured that their compressors are engineered for maximum reliability and performance.

Importance of Insulation in Truck Refrigeration

Insulation is one aspect often overlooked but crucial for maintaining optimal temperatures within any refrigerated space—especially in trucks where ambient conditions can fluctuate dramatically. Effective insulation minimizes heat transfer between external environments and internal spaces, thus enhancing overall efficiency in how does a truck refrigeration unit work? Poor insulation leads to increased energy consumption as units struggle to maintain set temperatures.

Additionally, proper insulation contributes significantly to extending product shelf life during transit by creating stable conditions inside van refrigeration units or other types of refrigerated trucks. When assessing options from various commercial truck refrigeration unit manufacturers, consider those who prioritize advanced insulation techniques as part of their design philosophy. For example, Arctic Active Cooling's systems not only offer efficient cooling but also integrate quality insulation materials for added performance.

Types of Refrigerants Used

What Refrigerant Is Used in Refrigerated Trucks?

Refrigerated trucks typically use a variety of refrigerants, with R-134a and R-404A being among the most common choices. These refrigerants are specifically designed to work efficiently within the cooling cycle, ensuring that the truck refrigeration system can maintain optimal temperatures during transport. As you ponder over what refrigerant is used in refrigerated trucks?, it's essential to note that newer options like R-452A are gaining popularity due to their lower environmental impact.

Impact of Refrigerants on Efficiency

The choice of refrigerant can significantly impact how do truck fridges work? A more efficient refrigerant allows for better heat absorption and transfer, resulting in lower energy consumption and enhanced cooling capacity. This means that not only do you get a reliable truck refrigeration system, but you also save on fuel costs—an important consideration for any commercial truck refrigeration unit manufacturer aiming to meet customer expectations.

Regulatory Factors Affecting Refrigerant Choices

Regulatory factors play a pivotal role in determining what refrigerant is used in refrigerated trucks. Governments worldwide are increasingly imposing restrictions on certain high-GWP (Global Warming Potential) substances, pushing manufacturers toward more environmentally friendly options. As regulations evolve, commercial truck refrigeration unit manufacturers must adapt their designs and materials to comply while still delivering effective solutions—making it an ongoing challenge within the industry.

Assessing Cooling Capacity and Efficiency

When it comes to the performance of a truck refrigeration system, understanding how these units operate is essential. A truck refrigeration unit is designed to keep perishable goods at optimal temperatures during transport, ensuring freshness upon delivery. By assessing how do truck fridges work, you can better appreciate the technology that goes into maintaining controlled environments for various cargo types.

How Do Truck Fridges Work?

Truck fridges operate on the principles of thermodynamics and utilize a closed-loop refrigeration cycle. At the heart of this cycle are the four components of a refrigeration system: compressor, condenser, expansion valve, and evaporator. Each component plays a vital role in transferring heat away from the cargo area, allowing refrigerated trucks to maintain lower temperatures effectively.

The compressor compresses refrigerant gas, raising its pressure and temperature before sending it to the condenser. Here, the gas releases heat and transforms into a liquid state while passing through coils exposed to outside air. The refrigerant then travels through an expansion valve where it expands and cools before entering the evaporator—this process effectively chills the air inside the truck’s cargo area.

Factors Influencing Cooling Capacity

Several factors influence cooling capacity in a truck refrigeration system, which can significantly impact product quality during transit. For instance, ambient temperature plays a crucial role; higher outside temperatures require more energy to maintain desired internal conditions. Additionally, insulation quality within refrigerated trucks greatly affects their efficiency—better insulation means less energy consumption while keeping contents cool.

Another factor is load size; overloading can strain cooling systems and reduce overall efficiency. The type of goods being transported also matters; some items require specific temperature settings that may demand more from your commercial truck refrigeration unit manufacturer’s design specifications. Understanding these factors will help you make informed decisions when choosing or upgrading your refrigerated transport solutions.

Energy Efficiency Ratings in Refrigeration Systems

Energy efficiency ratings are critical indicators of how well a truck refrigeration system performs relative to its energy consumption. These ratings provide insights into operational costs over time as well as environmental impacts associated with energy use—important considerations for any business looking to optimize their logistics operations. Manufacturers often provide detailed information about energy efficiency ratings for their products; thus making comparisons easier among different models.

When selecting a unit such as Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit, it's essential to consider these ratings alongside performance metrics like cooling capacity and durability under various conditions. This particular model is designed for commercial refrigerators and freezers while maintaining optimal humidity levels—a crucial feature when transporting sensitive items like fresh flowers or pharmaceuticals.

By prioritizing energy-efficient options within your fleet management strategy, you not only save on fuel costs but also contribute positively towards sustainability goals in logistics operations—an increasingly important aspect in today’s eco-conscious market.

Choosing the Right Manufacturer

Selecting the right manufacturer for your truck refrigeration system is crucial to ensure reliability, efficiency, and longevity. The market is filled with options, but not all manufacturers offer the same level of quality or support. Understanding who stands out in this competitive landscape can help you make an informed decision.

Top Commercial Truck Refrigeration Unit Manufacturers

When it comes to commercial truck refrigeration unit manufacturers, a few names consistently rise to the top. Brands like Carrier Transicold and Thermo King have established themselves as leaders in the industry, known for their robust designs and innovative technology. However, Arctic Active Cooling has emerged as a strong contender with its advanced Top-Mounted Monoblock Refrigeration Unit, which promises unparalleled efficiency and reliability for various cooling applications.

These leading manufacturers offer units that cater to different needs—from large-scale transport operations to smaller businesses requiring van refrigeration units. Their products are engineered to withstand harsh conditions while maintaining optimal temperature control, ensuring that perishable goods stay fresh during transport. When considering a manufacturer, it’s essential to assess their range of products and how well they align with your specific requirements.

Evaluating Manufacturer Reputation and Support

Reputation matters when choosing a commercial truck refrigeration unit manufacturer. Look for companies that have built trust over time through positive customer reviews and industry recognition. A reputable manufacturer will not only provide quality products but also offer reliable support services—essential when dealing with something as critical as your truck refrigeration system.

It's wise to investigate how responsive a manufacturer is regarding warranties, repairs, and customer service inquiries. A solid support system can save you time and money should any issues arise with your refrigeration unit down the line. Additionally, check if they provide comprehensive resources such as installation guides or maintenance tips—these are invaluable for maximizing the lifespan of your truck fridges.

Comparing Arctic Active Cooling and Competitors

When comparing Arctic Active Cooling's offerings against competitors like Carrier Transicold or Thermo King, it's important to focus on performance metrics such as energy efficiency ratings and cooling capacity. For instance, Arctic's Top-Mounted Monoblock Refrigeration Unit stands out due to its innovative design tailored for cold rooms in various applications—from florists needing optimal humidity levels for flower storage to restaurants requiring consistent temperatures for perishables.

While each brand has its strengths, assessing factors such as ease of installation—How does a truck refrigeration unit work?—and overall maintenance requirements can help you make an educated choice based on your operational needs. Additionally, consider what refrigerant is used in refrigerated trucks from each manufacturer; this can affect both efficiency levels and regulatory compliance aspects of your business.

In conclusion, choosing the right manufacturer involves more than just picking a name off a list; it requires careful consideration of reputation, product offerings like van refrigeration units versus traditional systems, and excellent customer support that meets your unique needs.

Conclusion

In summary, understanding the intricacies of a truck refrigeration system is vital for anyone involved in transporting perishable goods. From knowing how does a truck refrigeration unit work to recognizing the importance of insulation, every aspect plays a crucial role in ensuring that products remain fresh and safe. Additionally, assessing the right commercial truck refrigeration unit manufacturer can make all the difference in efficiency and reliability.

Recap of Essential Considerations

When considering a truck refrigeration system, it's essential to evaluate its key components: the compressor, condenser, evaporator, and expansion valve—what are the 4 components of a refrigeration system? Each part has its unique function that contributes to optimal cooling performance. Furthermore, understanding what refrigerant is used in refrigerated trucks is critical for compliance with environmental regulations and overall efficiency.

Importance of Customization in Refrigeration Systems

Customization in refrigeration systems allows businesses to tailor solutions to their specific needs, especially when comparing van refrigeration units with larger truck systems. The ability to modify cooling capacity based on cargo type ensures that products are stored under ideal conditions. Moreover, manufacturers like Arctic Active Cooling offer innovative options such as their Top-Mounted Monoblock Refrigeration Unit for various applications—proving that one size does not fit all.

Future Trends in Truck Refrigeration Technology

The future of truck refrigeration technology looks promising with advancements aimed at enhancing energy efficiency and reducing environmental impact. Innovations such as smart monitoring systems could revolutionize how we assess cooling performance and respond proactively to potential issues—answering the question: how do truck fridges work? As regulations evolve concerning what refrigerant is used in refrigerated trucks, manufacturers will need to adapt quickly while maintaining high standards for reliability.