Introduction

"Arctic Active Cooling. Endless Possibilities. We capture new technologies in mobile and compact cooling. Full-size cooling in a miniature design, customized to make your device stand out with innovative thermal management."

Maintaining the ideal cold room temperature is crucial for preserving perishable goods, ensuring food safety, and optimizing storage conditions. The question often arises: what is the ideal temperature for a cold room? This temperature varies depending on the type of items stored; for instance, vegetable cold room temperatures typically hover between 0°C to 4°C, while cold room temperature for meat should be kept at around -1°C to 2°C.

However, managing a cold room comes with its fair share of challenges. Fluctuations in temperature can lead to spoilage, affecting both quality and safety. Common issues include equipment failures, improper insulation, and inadequate monitoring systems that can compromise the integrity of your stored products.

To navigate these challenges successfully, implementing best practices is essential. Utilizing tools such as a cold room temperature chart can help maintain precise control over conditions within the space. Additionally, employing advanced solutions like the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit ensures reliability and efficiency in maintaining optimal cold room temperatures.

Understanding Cold Room Temperature

Cold room temperature is a critical factor in preserving the quality and safety of perishable goods. Maintaining the right temperature not only extends shelf life but also prevents spoilage and foodborne illnesses. Understanding what constitutes ideal cold room temperature is essential for effective cold room management.

What is Ideal Cold Room Temperature?

So, what is the ideal temperature for a cold room? Generally, for most perishable items, maintaining a cold room temperature between 0°C to 4°C (32°F to 39°F) is optimal. For specific items like vegetables, the vegetable cold room temperature typically ranges from 0°C to 2°C (32°F to 36°F), while for meat products, it’s crucial to keep the cold room temperature at or below 4°C (39°F) to ensure freshness and safety.

Utilizing a cold room temperature chart can be incredibly helpful in determining the best storage conditions for various products. This chart acts as your quick reference guide, allowing you to adjust your cooling systems accordingly based on what you’re storing. By adhering closely to these guidelines, businesses can maximize product quality and minimize waste.

Effects of Improper Temperature Control

Improper control of cold room temperatures can lead to disastrous consequences for stored goods. When temperatures rise above recommended levels, perishable items can spoil quickly, leading not just to financial loss but also potential health hazards due to foodborne pathogens thriving in warmer conditions. For instance, meat stored above the recommended cold room temperature may become unsafe for consumption within hours.

Additionally, fluctuations in cold room temperatures can degrade product quality over time—think wilted vegetables or freezer-burnt meats—resulting in unsatisfied customers and diminished brand reputation. It’s essential that businesses take these risks seriously by ensuring that their refrigeration systems are functioning optimally at all times. Regular monitoring helps catch any deviations before they turn into significant issues.

Measuring Cold Room Temperature Accurately

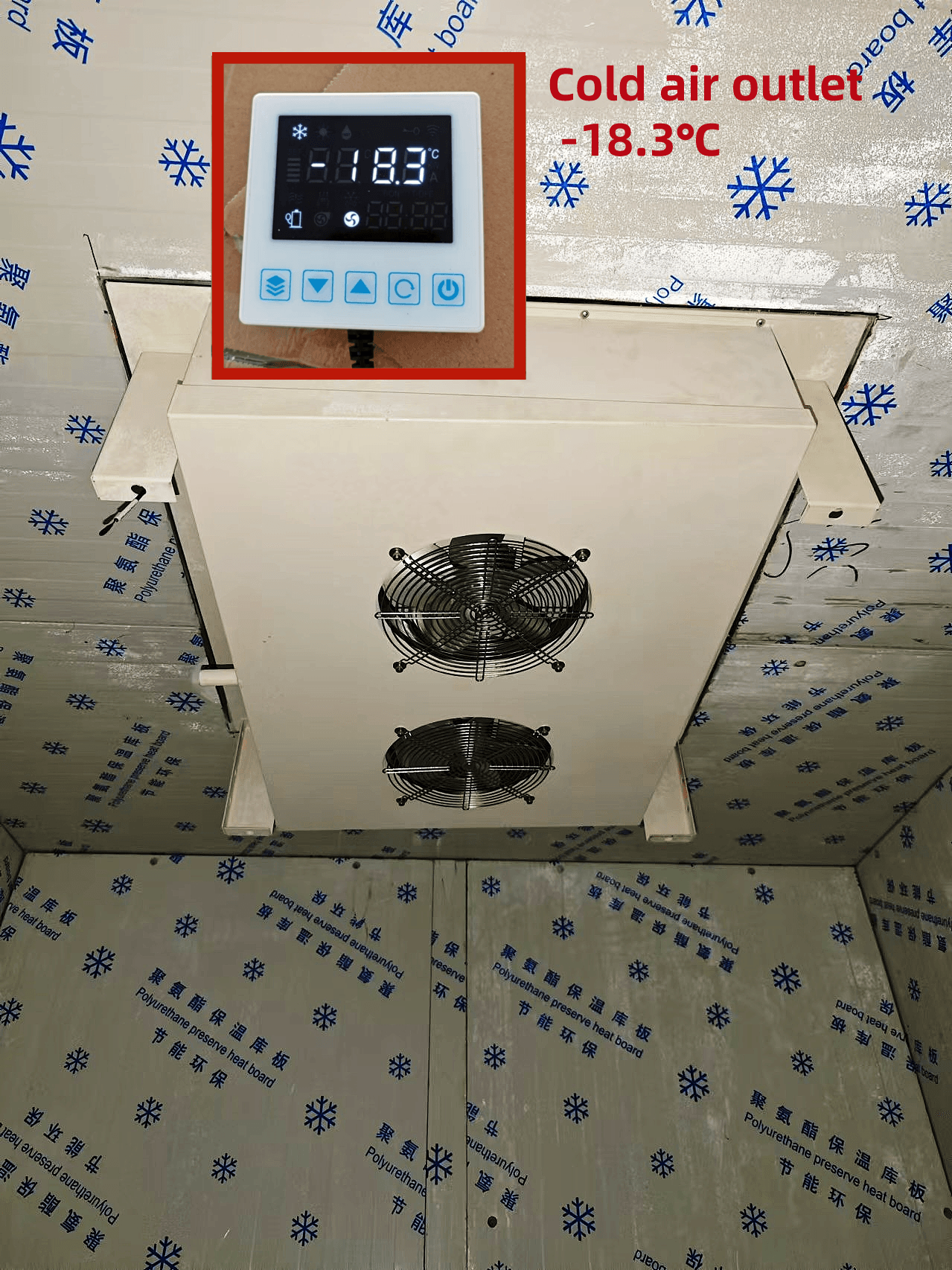

Accurate measurement of cold room temperatures is vital for effective management and compliance with safety standards. Using a reliable cold room temperature controller allows operators to monitor conditions continuously and make adjustments as necessary—no more guessing games! Many modern controllers come equipped with digital displays that provide real-time readings along with data logging features that help maintain a comprehensive record through a cold room temperature record sheet.

To ensure accuracy, it’s advisable to place multiple thermometers throughout the space since different areas may experience varying temperatures due to airflow patterns or equipment placement. Regular calibration of measuring devices will further enhance precision; after all, even minor discrepancies can lead to major problems down the line! By keeping an eye on these metrics consistently, businesses can ensure optimal storage conditions are maintained at all times.

Selecting the Right Refrigeration Unit

Choosing the right refrigeration unit is crucial for maintaining the ideal cold room temperature, ensuring that your stored products remain fresh and safe. With various options available, understanding the features and benefits of each type can help you make an informed decision. This section will delve into Arctic Active Cooling solutions, how to select the appropriate size and type of unit, and why energy efficiency should be a top priority.

Benefits of Arctic Active Cooling Solutions

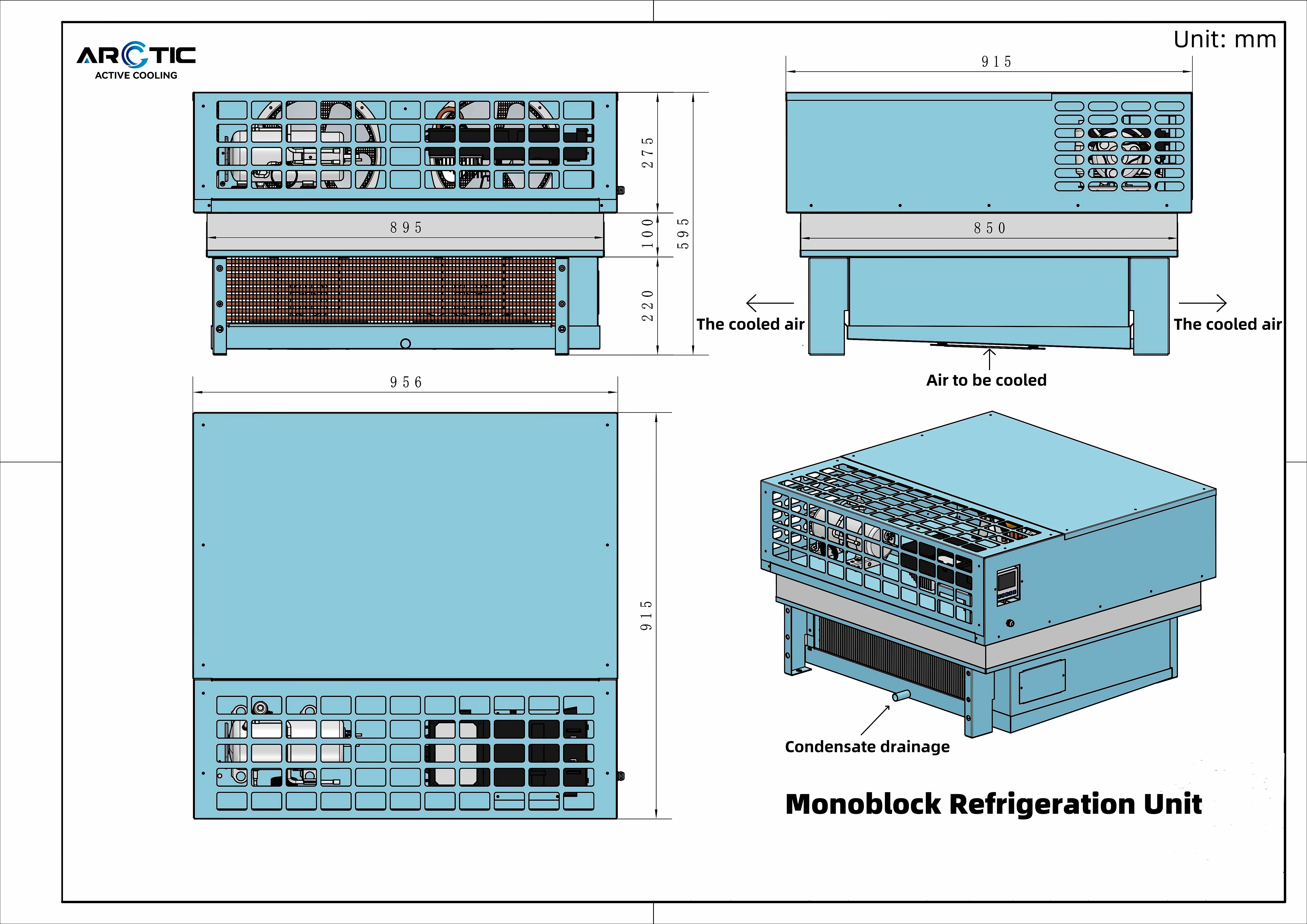

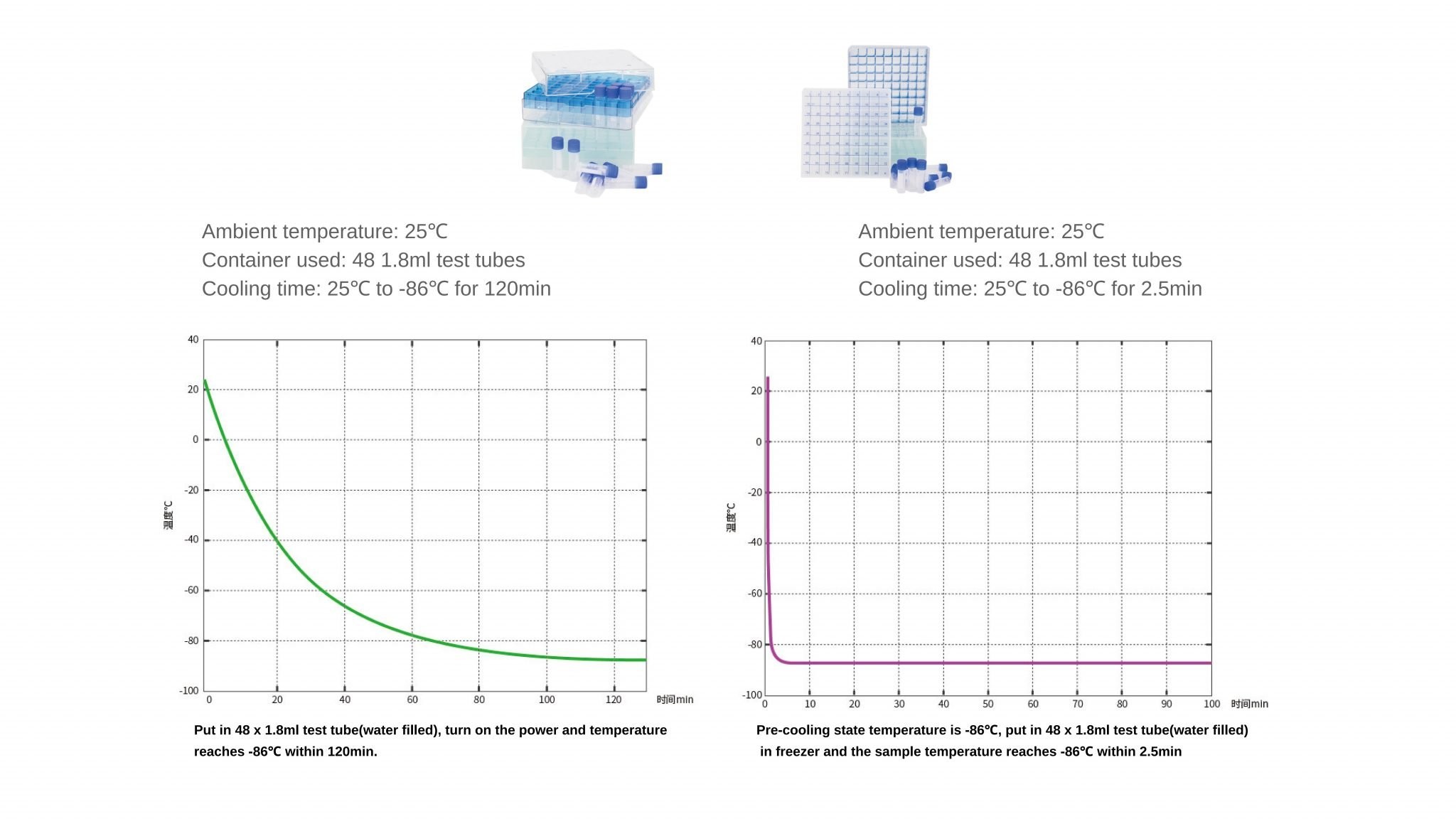

Their Top-Mounted Monoblock Refrigeration Unit is designed specifically for commercial refrigerators, freezers, and small to mid-sized cold rooms, making it a versatile choice for various applications. By investing in this advanced cooling technology, businesses can enjoy unparalleled efficiency and reliability while ensuring their products are stored at the correct vegetable cold room temperature or even specific temperatures for meat storage.

Moreover, these units are engineered with sustainability in mind; they consume less energy while delivering superior cooling performance. This means not only do you maintain a consistent cold room temperature but also save on energy costs over time. With features like easy installation and low maintenance requirements, Arctic Active Cooling solutions simplify your refrigeration needs while optimizing your operations.

Choosing the Right Size and Type

Selecting the appropriate size and type of refrigeration unit is essential for maintaining ideal cold room temperatures effectively. A unit that is too small may struggle to keep up with demand, leading to fluctuations in temperature that could compromise food safety or product quality. Conversely, an oversized unit can result in unnecessary energy consumption without providing any additional benefit to your storage capabilities.

To determine what is the ideal temperature for a cold room based on your specific needs—whether it's a vegetable cold room temperature or one designed for meat—you must consider factors such as storage volume and product types being held. Additionally, consult a reliable cold room temperature chart to guide you in selecting units that align with industry standards for different products. Remember that proper sizing not only enhances cooling efficiency but also prolongs equipment life.

Importance of Energy Efficiency in Refrigeration

In today's environmentally conscious world, energy efficiency has become more than just a buzzword; it's a necessity when selecting refrigeration units for maintaining optimal cold room temperatures. Energy-efficient models help reduce operational costs while minimizing environmental impact—an appealing combination for any business owner aiming to maintain profitability without sacrificing quality or safety standards.

When evaluating refrigeration options like those from Arctic Active Cooling, look beyond initial purchase price; consider long-term savings associated with lower energy bills as well as potential rebates or incentives available through utility companies for choosing high-efficiency equipment. Additionally, using tools such as a cold room temperature record sheet can assist you in monitoring performance over time—ensuring that your chosen system consistently operates within desired parameters.

Ultimately, investing in an energy-efficient refrigeration solution not only supports sustainable practices but also contributes positively to overall business performance by enhancing reliability and reducing downtime due to equipment failure.

Proper Insulation Techniques

When it comes to maintaining an optimal cold room temperature, proper insulation techniques are essential. Insulation not only helps in achieving the ideal temperature for a cold room but also plays a crucial role in energy efficiency. By understanding and implementing effective insulation strategies, you can prevent heat infiltration that could compromise the integrity of your cold storage.

Understanding Insulation Materials

Choosing the right insulation materials is vital for controlling cold room temperature effectively. Common materials include foam boards, fiberglass batts, and spray foam, each with its own unique properties that contribute to thermal resistance. For instance, foam boards provide excellent R-values and moisture resistance, making them ideal for vegetable cold room temperatures where humidity control is necessary.

In addition to traditional materials, consider advanced options such as reflective insulation or insulated panels that can further enhance cooling efficiency. The right choice depends on factors like climate conditions and specific storage needs—like the cold room temperature for meat versus vegetables. Always refer to a cold room temperature chart to determine which materials will best suit your requirements.

Sealing Gaps and Cracks

Even the best insulation can't do its job if there are gaps or cracks in your structure. Sealing these openings is crucial for maintaining the desired cold room temperature and preventing energy loss. Use weather stripping or caulk to seal around doors, windows, and any penetrations in walls where pipes or wiring enter.

Regularly inspecting your facility will help you identify areas that need attention; after all, even small gaps can lead to significant fluctuations in your cold room temperature record sheet over time! Ensuring airtight seals contributes not just to stability but also enhances the performance of systems like the Arctic Active Cooling Top-Mounted Monoblock Refrigeration Unit by reducing workload on refrigeration units.

Maintaining Insulation Over Time

To ensure long-lasting effectiveness of your insulation techniques, routine maintenance is key. Over time, wear and tear can degrade insulation materials or cause seals to break down—both of which negatively impact your ability to maintain an ideal cold room temperature. Schedule regular inspections specifically focused on checking for moisture damage or physical deterioration of insulating materials.

Also remember that cleaning dust and debris from insulated surfaces can improve their effectiveness; this includes areas around refrigeration units where heat exchange occurs frequently due to airflow disruptions caused by dirt buildup. By keeping an eye on both material integrity and cleanliness, you’ll be well-equipped to maintain optimal conditions within your space while utilizing tools like a cold room temperature controller effectively.

Regular Maintenance Practices

Maintaining the ideal cold room temperature is crucial for preserving perishable goods such as vegetables and meats. Regular maintenance practices not only help in achieving optimal cooling but also extend the lifespan of refrigeration units. Implementing a routine can prevent costly breakdowns and ensure that your cold room operates efficiently.

Scheduled Equipment Checks

Regular equipment checks are essential to ensure that your cold room temperature remains within the desired range. What is the ideal temperature for a cold room? Generally, it should be around 0°C to 4°C for meat storage, while vegetable cold room temperature may vary between 0°C and 10°C depending on the type of produce. By scheduling these checks monthly or quarterly, you can identify potential issues before they escalate into major problems, keeping your cold room temperature stable.

Importance of Cleaning and Servicing

Cleaning and servicing your refrigeration unit are vital components of maintaining proper cold room conditions. Dust and debris can accumulate on coils and filters, hindering efficiency and causing fluctuations in cold room temperature in Celsius. Regularly cleaning these components not only helps maintain an ideal environment but also prolongs the life of your equipment—after all, a clean unit is a happy unit!

Quick Fixes for Common Issues

Even with regular maintenance, issues can arise that require immediate attention to maintain optimal conditions in your cold room. Keeping a cold room temperature record sheet handy allows you to track fluctuations and address them swiftly if they occur. Common quick fixes include adjusting the thermostat or checking seals; however, knowing when to call in professionals is equally important to avoid further complications.

Monitoring and Control Systems

In the realm of cold room management, monitoring and control systems are indispensable for maintaining optimal cold room temperature. These systems not only ensure that the environment remains conducive for various products, such as meat and vegetables, but also help in adhering to safety standards. By implementing effective monitoring solutions, businesses can avoid costly losses due to temperature fluctuations.

Importance of Temperature Monitoring Systems

Temperature monitoring systems are vital for tracking cold room temperature in real-time, allowing managers to respond swiftly to any anomalies. Understanding what is the ideal temperature for a cold room is crucial; typically, it should be around 0°C to 4°C for meat and slightly higher for vegetables. Without a reliable system in place, businesses risk compromising product quality and safety, which can lead to significant financial repercussions.

Utilizing Smart Technology for Efficiency

The integration of smart technology into cold room management has revolutionized how businesses monitor their refrigeration needs. Utilizing advanced solutions like Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit enhances efficiency by providing precise control over cold room temperature. These smart units can connect with mobile apps or cloud-based systems, enabling users to adjust settings remotely and optimize energy consumption while keeping a close eye on the cold room temperature chart.

Setting Alerts for Temperature Fluctuations

Setting alerts for temperature fluctuations is a proactive measure that can safeguard your products from spoilage due to improper cooling conditions. By using features available in modern cold room temperature controllers, users can receive instant notifications if temperatures deviate from preset thresholds. This capability allows quick action—whether it’s adjusting settings on the cold room temperature record sheet or troubleshooting equipment issues—ensuring that your investments remain protected against unexpected changes.

Conclusion

In summary, maintaining the ideal cold room temperature is crucial for preserving the quality and safety of stored items. Understanding what is the ideal temperature for a cold room can significantly minimize spoilage and waste, especially when it comes to sensitive products like meat and vegetables. Regular monitoring and employing advanced technology such as a cold room temperature controller can ensure that your cooling environment remains optimal.

Key Takeaways for Maintaining Cold Room Temperature

To maintain an effective cold room temperature, it's essential to adhere to established standards based on your specific storage needs. For instance, vegetable cold room temperature typically ranges from 0°C to 4°C, while cold room temperature for meat should be maintained at around -1°C to 2°C. Utilizing tools like a cold room temperature chart can help you keep track of these requirements effortlessly.

Long-Term Benefits of Proper Cooling Practices

Implementing best practices in managing your cold room not only safeguards product integrity but also enhances operational efficiency over time. By ensuring consistent cold room temperatures, businesses can reduce losses due to spoilage and improve customer satisfaction with fresher products. Additionally, energy-efficient solutions like Arctic Active Cooling’s Top-Mounted Monoblock Refrigeration Unit contribute to lower utility bills while maintaining optimal conditions.

Final Thoughts on Efficient Cold Room Management

Efficient cold room management is not just about keeping things cool; it's about creating an environment where quality thrives and waste diminishes. By regularly updating your practices—whether through scheduled equipment checks or using a cold room temperature record sheet—you can stay ahead of potential issues before they escalate into costly problems. Ultimately, investing in proper cooling practices today will pay dividends tomorrow, ensuring that your business remains competitive in an ever-evolving market.